Ultrahigh pressure primary reheat power generation system

A thermal power generation system and ultra-high pressure technology, applied in the directions of preheating, steam superheating, steam generation, etc., can solve the problems of difficult heat balance in reheater layout, inability to stably control the steam temperature at the outlet of the reheater, etc., to improve efficiency and economy. Benefit, the effect of stable outlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below according to specific embodiments.

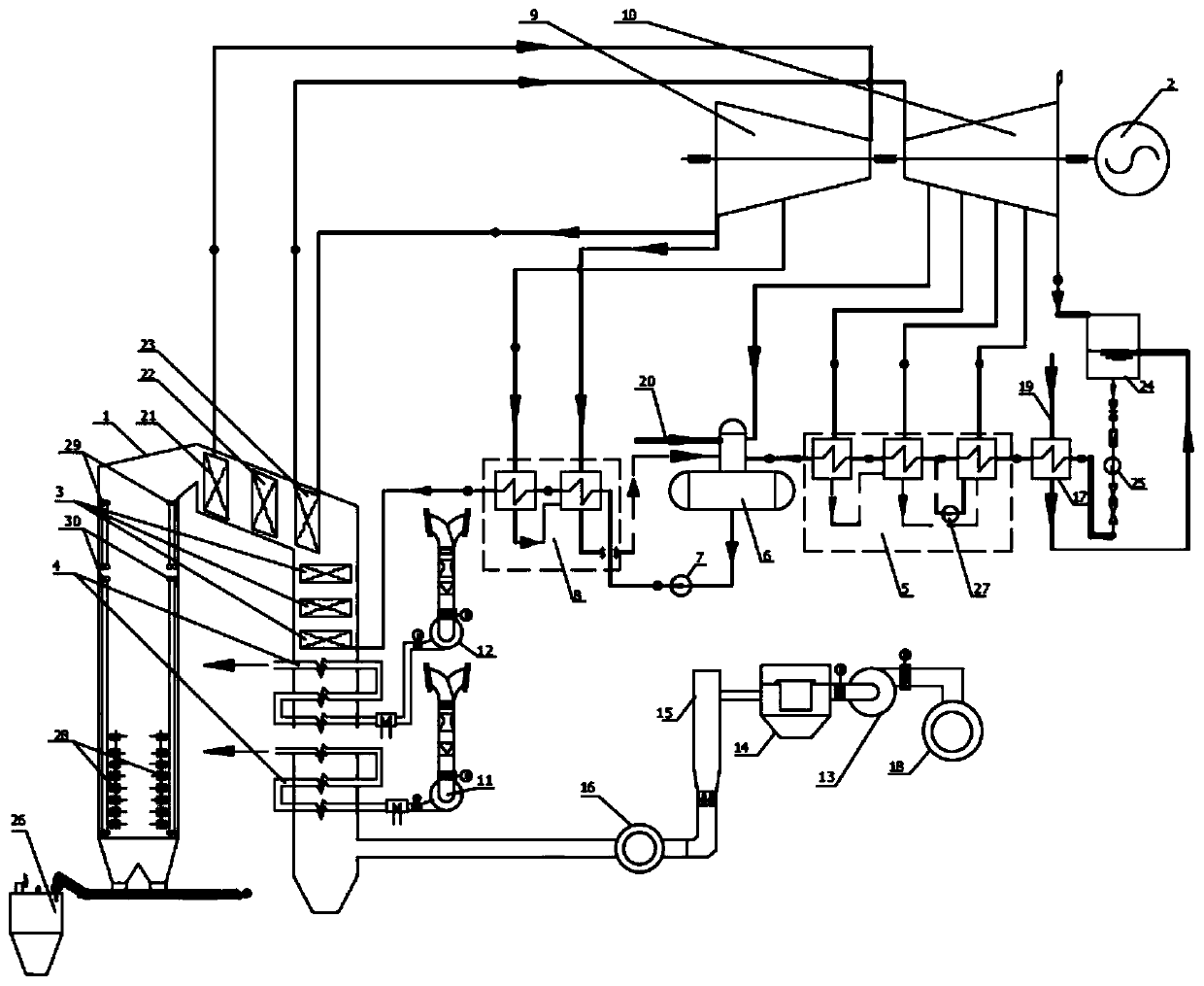

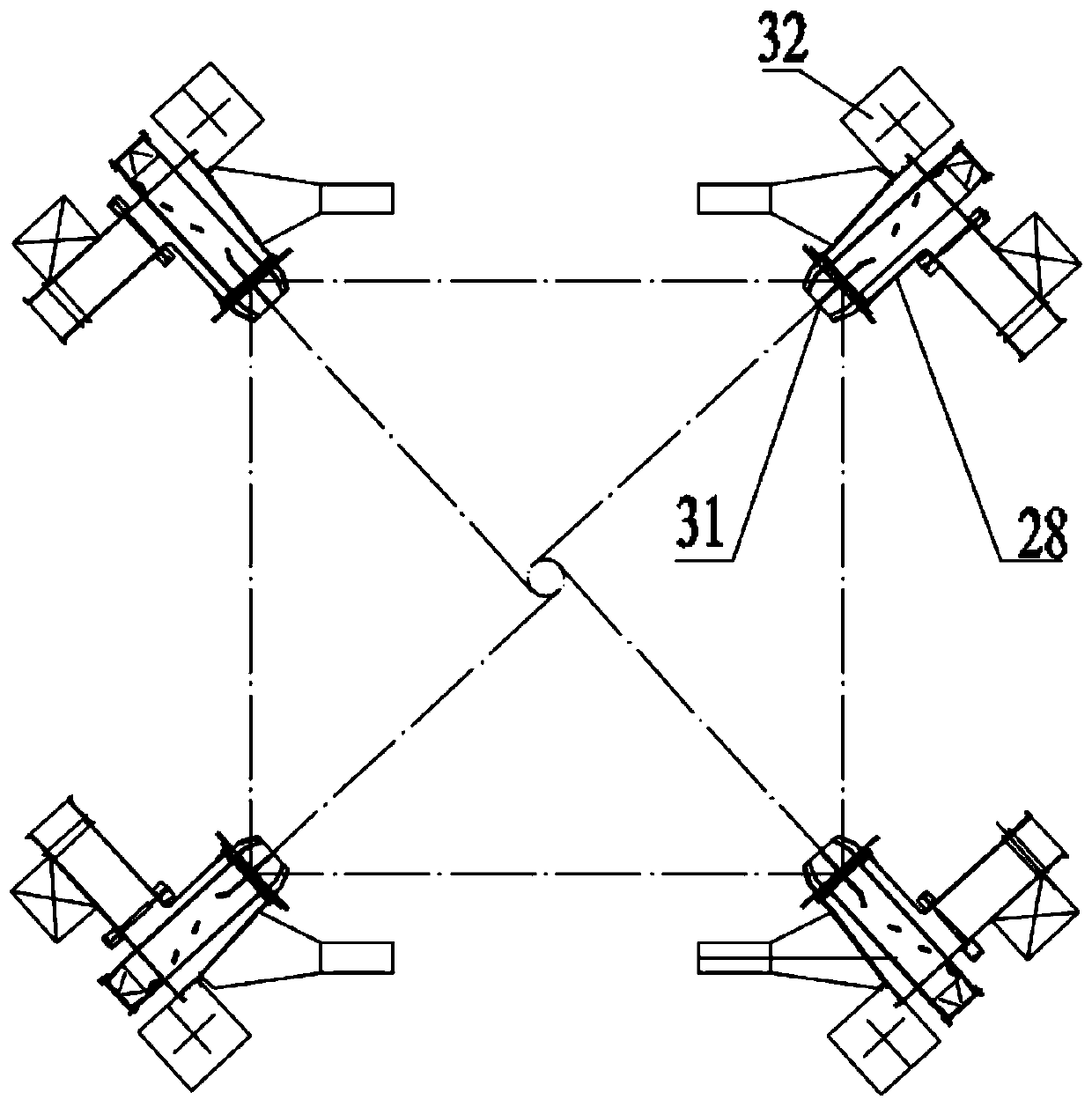

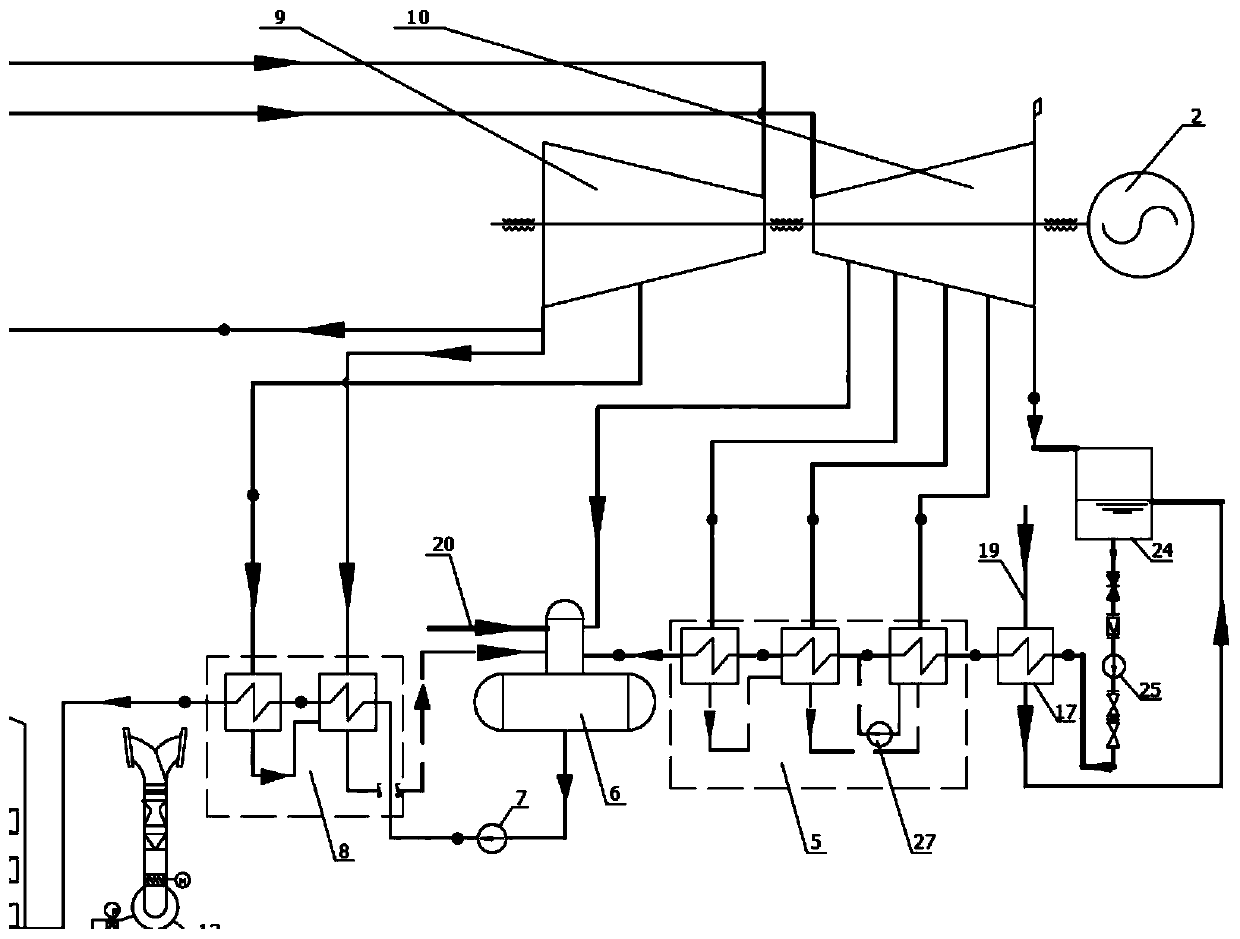

[0023] Such as Figure 1-4 The ultra-high pressure primary reheat power generation system shown includes a steam turbine and a combustion boiler 1. The combustion boiler 1 can adopt various forms of combustion boilers such as pulverized coal furnace, circulating fluidized bed boiler, and grate furnace. In this embodiment, The combustion boiler 1 adopts a pulverized coal furnace, and the steam turbine is connected with a generator 2. The steam turbine includes a steam turbine high pressure cylinder 9 and a steam turbine low pressure cylinder 10. The combustion boiler 1 is provided with an evaporating water wall 30, a swing burner 28, a wall reheater 29, High temperature superheater 21, low temperature superheater 22, reheater 23, economizer 3, air preheater 4, air preheater 4 is connected with primary fan 11 and secondary fan 12, the bottom flue of combustion boiler 1 The main du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com