Method for preventing nitrogen increase of molten steel in LF (Ladle Furnace) refining process by top-blowing argon gas

A refining process and top blowing technology, applied in the field of metallurgical technology, can solve problems such as increased cost, large amount of slag, unfavorable operation, etc., achieve significant social and economic benefits, and improve the quality of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

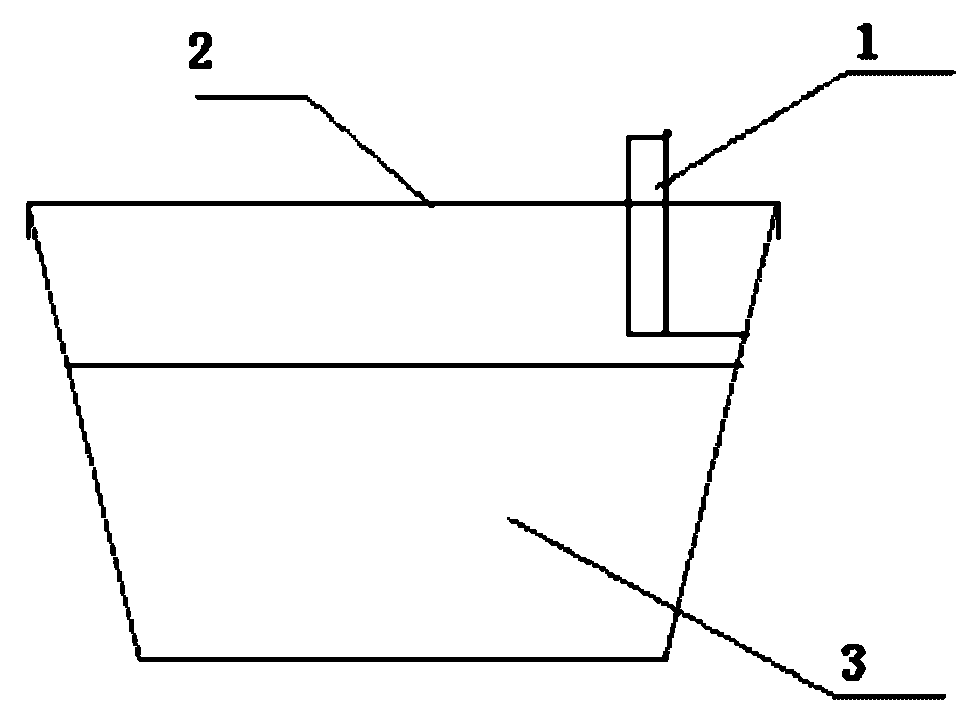

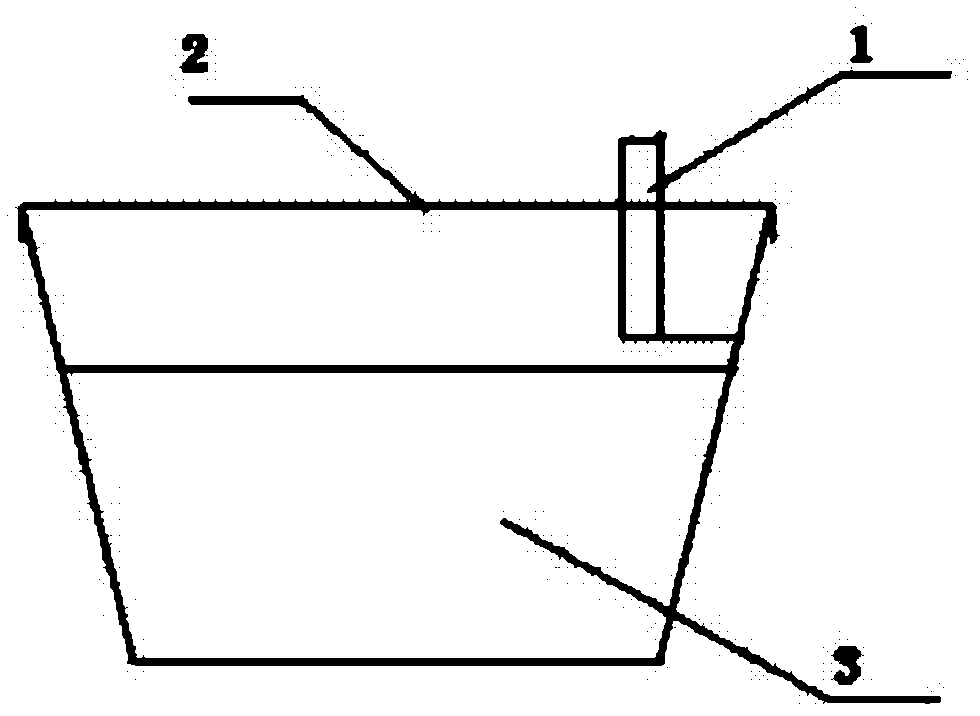

Image

Examples

Embodiment 1

[0017] After the ladle enters the LF processing station, lower the top-blown argon gun to 140mm above the liquid surface, blow in pure argon, the flow rate of the argon gas is 20NL / min, create an inert gas environment, and stably control the amount of nitrogen added to the molten steel to less than 5ppm, carry out normal LF refining treatment, after refining for 75 minutes, the argon gun stops blowing argon, lifts the argon gun, and the ladle leaves the processing station.

Embodiment 2

[0019] After the ladle enters the LF treatment station, lower the accidental argon gun to 170mm above the liquid surface, blow in pure argon gas, and the flow rate of argon gas is 45NL / min to create an inert gas environment, and stably control the amount of nitrogen added to the molten steel to less than 5ppm, carry out normal LF refining treatment, after refining for 47 minutes, stop blowing argon from the argon gun, lift the argon gun, and open the ladle to the treatment station.

Embodiment 3

[0021] After the ladle enters the LF processing station, lower the top-blowing argon gun to 150mm above the liquid surface, blow in pure argon, the flow rate of the argon gas is 80NL / min, create an inert gas environment, and stably control the amount of nitrogen added to the molten steel to less than 5ppm, carry out normal LF refining treatment, after refining for 50 minutes, the argon gun stops blowing argon, lifts the argon gun, and the ladle leaves the processing station.

[0022] Table 1 Example of LF anti-nitrogen production process

[0023] serial number N content in front of LF furnace, wt% N content after LF, wt% Nitrogen addition, wt% 1 0.0023 0.0028 0.0005 2 0.0022 0.0024 0.0002 3 0.0026 0.0027 0.0001

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com