Antioxidant toughening modified polyphenylene sulfide monofilament and preparation method thereof

A technology of polyphenylene sulfide and toughening modification, which is applied in the manufacture of rayon, single-component synthetic polymer rayon, melt spinning, etc., can solve the problems of poor oxidation resistance and brittleness, and achieve low cost and high production efficiency. Excellent process stability, oxidation resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

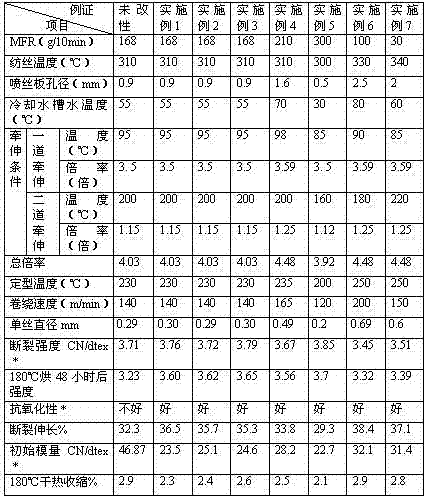

Examples

Embodiment 1

[0066] Using the MFR of 168g / 10min linear polyphenylene sulfide raw powder, its structural unit content ≥ 90% mol / mol to produce anti-oxidation toughened modified polyphenylene sulfide chips through the following formula:

[0067] PPS raw powder: 96%

[0068] Antioxidant AO1179: 0.2%

[0069] Antioxidant AO110: 0.2%

[0070] Nano calcium carbonate: 2.6%

[0071] Dispersion coupling agent EK602: 1%

[0072] Preparation of anti-oxidation and toughening modified polyphenylene sulfide chips: Add antioxidant, toughening agent and dispersing coupling agent to PPS raw powder, mix uniformly in a high-speed mixer and dry; mix and dry PPS raw The powder is extruded by a twin-screw extruder and pelletized to make anti-oxidation toughened modified polyphenylene sulfide chips for spinning to produce PPS monofilaments.

[0073] Preparation of anti-oxidative and toughened polyphenylene sulfide monofilaments: before melt spinning, the polyphenylene sulfide chips were dried in ...

Embodiment 2

[0075] Use the MFR of 200g / 10min linear polyphenylene sulfide raw powder, and its structural unit content is ≥70% mol / mol to produce anti-oxidation toughened modified polyphenylene sulfide chips through the following formula:

[0076] PPS raw powder: 95.8%

[0077] Antioxidant AO1179: 0.3%

[0078] Nano calcium carbonate: 2.9%

[0079] Dispersion coupling agent EK602: 1%

[0080] Preparation of anti-oxidation and toughening modified polyphenylene sulfide chips: Add antioxidant, toughening agent and dispersing coupling agent to PPS raw powder, mix uniformly in a high-speed mixer and dry; mix and dry PPS raw The powder is extruded by a twin-screw extruder and pelletized to make anti-oxidation toughened modified polyphenylene sulfide chips for spinning to produce PPS monofilaments.

[0081] Preparation of anti-oxidative and toughened polyphenylene sulfide monofilaments: before melt spinning, the polyphenylene sulfide chips were dried in a vacuum drum with a moisture c...

Embodiment 3

[0083] Using the MFR of 168g / 10min linear polyphenylene sulfide raw powder, its structural unit content ≥ 90% mol / mol to produce anti-oxidation toughened modified polyphenylene sulfide chips through the following formula:

[0084] PPS raw powder: 97%

[0085] Antioxidant AO110: 0.3%

[0086] Nano calcium carbonate: 1%

[0087] Dispersion coupling agent EK602: 1.7%

[0088] Preparation of anti-oxidation and toughening modified polyphenylene sulfide chips: Add antioxidant, toughening agent and dispersing coupling agent to PPS raw powder, mix uniformly in a high-speed mixer and dry; mix and dry PPS raw The powder is extruded by a twin-screw extruder and pelletized to make anti-oxidation toughened modified polyphenylene sulfide chips for spinning to produce PPS monofilaments.

[0089] Preparation of anti-oxidative and toughened modified polyphenylene sulfide monofilaments: before melt spinning, the polyphenylene sulfide chips were dried in a vacuum drum with a moisture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap