A shell for induction logging tool and its design method

An induction logging and casing technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the inconvenience of installation, debugging and maintenance of induction logging instruments, and affect the use of internal coils and related components Life and other issues, to achieve the effect of meeting the requirements of non-magnetic insulation, shortening the length of the instrument, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

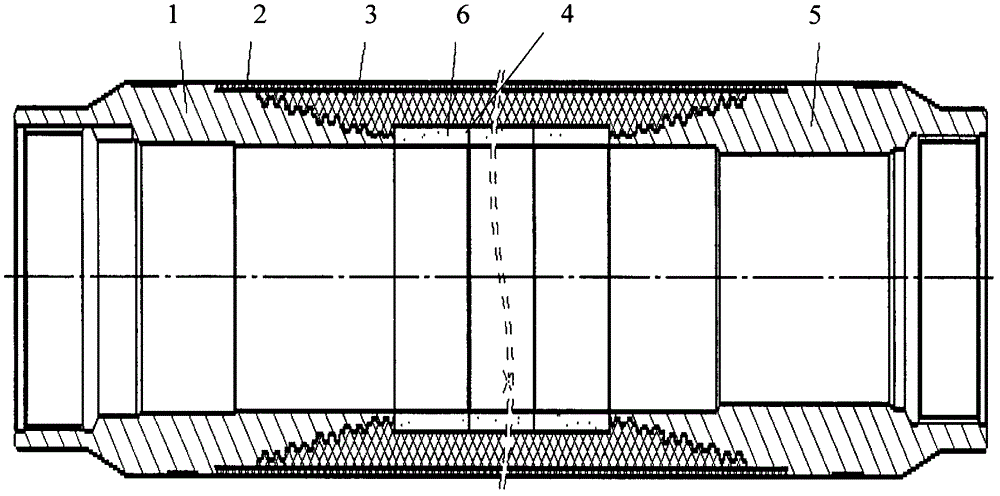

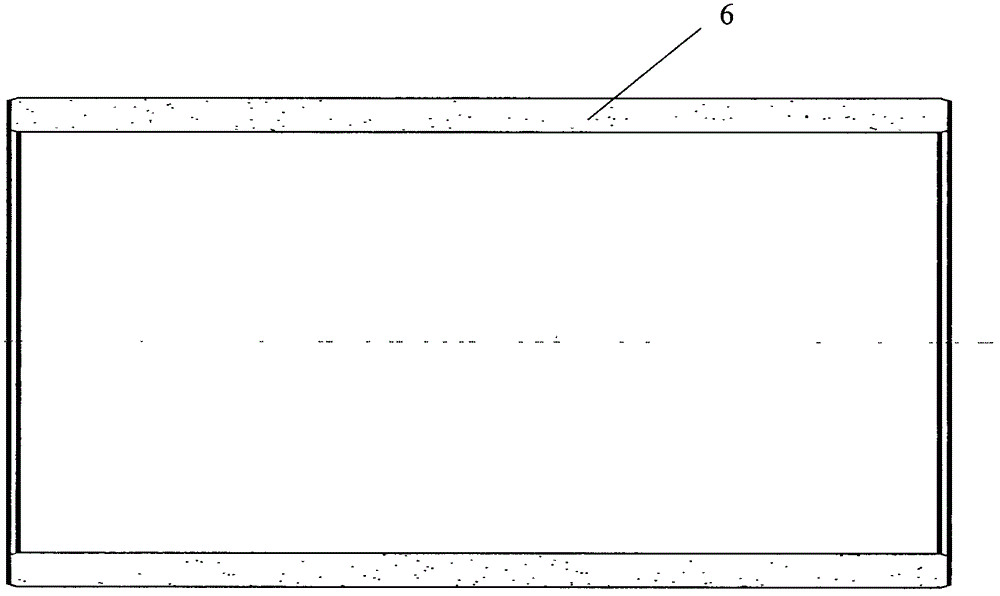

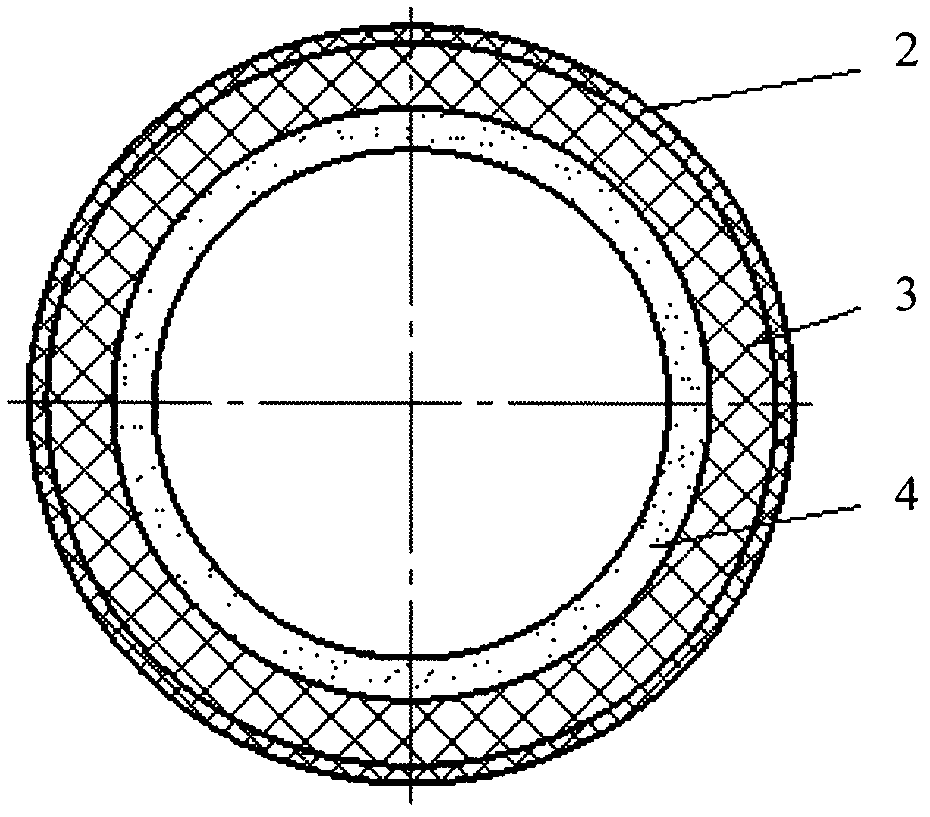

[0025] refer to figure 1 and image 3 , the present embodiment provides a casing for an induction logging tool, including a casing upper joint 1, a ceramic layer 4, a glass fiber reinforced plastic layer 3, a rubber layer 2 and a lower casing joint 5, the upper casing joint 1 and the lower casing joint 5 are both It is a hollow structure, and the ceramic layer 4, the glass fiber reinforced plastic layer 3 and the rubber layer 2 are set in sequence. The ceramic layer 4 is formed by bonding a plurality of ceramic rings 6 of the same specification, and the ceramic layer 4 is bonded to the upper joint 1 of the shell and the lower joint of the shell. 5, and the annular cavity of the ceramic layer 4 communicates with the hollow of the upper shell joint 1 and the shell lower joint 5, the glass fiber reinforced plastic layer 3 is located on the ceramic layer 4, and is connected with the shell lower joint 5 and the shell upper joint 1, and the rubber layer 2 is located on the FRP laye...

Embodiment 2

[0030] refer to figure 2 , the present embodiment provides a casing design scheme for an induction logging tool, which mainly includes the following steps:

[0031] Bond the ceramic ring 6 of the same specification to form the ceramic layer 4, bond one end of the ceramic layer 4 to the upper joint 1 of the shell, bond the other end of the ceramic layer 4 to the lower joint of the shell, and apply the sealant on the ceramic layer 4 The high-performance sealant and the ceramics are fully saturated to realize the insulated connection on the outside and each joint. The ceramic layer 4, the upper joint 1 of the shell and the lower joint 5 of the shell form a matrix, and the upper joint 1 of the shell and the lower joint 5 of the shell are all metal materials , the matrix formed by them and the ceramic layer 4 has a supporting effect on the outer shell layer;

[0032] Wrap FRP on the substrate to form a FRP layer 3, the FRP layer 3 is the middle layer of the casing, and is the mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com