Method for carrying out rapid face excavation construction of loess tunnel by double rows of small conduits

A technology of loess tunnel and construction method, which is applied in the direction of tunnel, tunnel lining, earth-moving drilling and mining, etc., can solve the problems of high cost, difficult to control the outside insertion angle, easy to produce large deformation and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] The embodiments of the present invention are not limited to the following examples, and various changes made without departing from the gist of the present invention fall within the protection scope of the present invention.

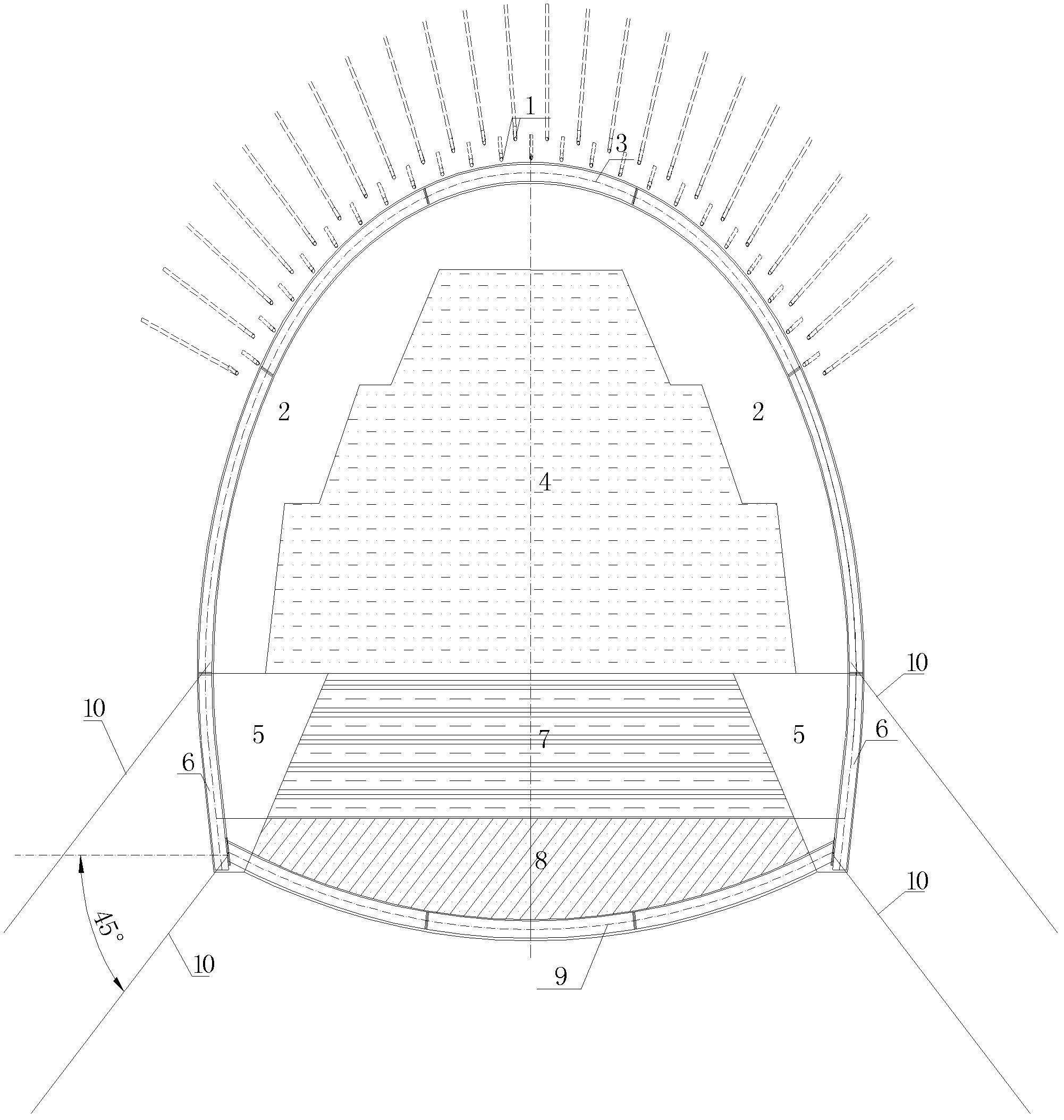

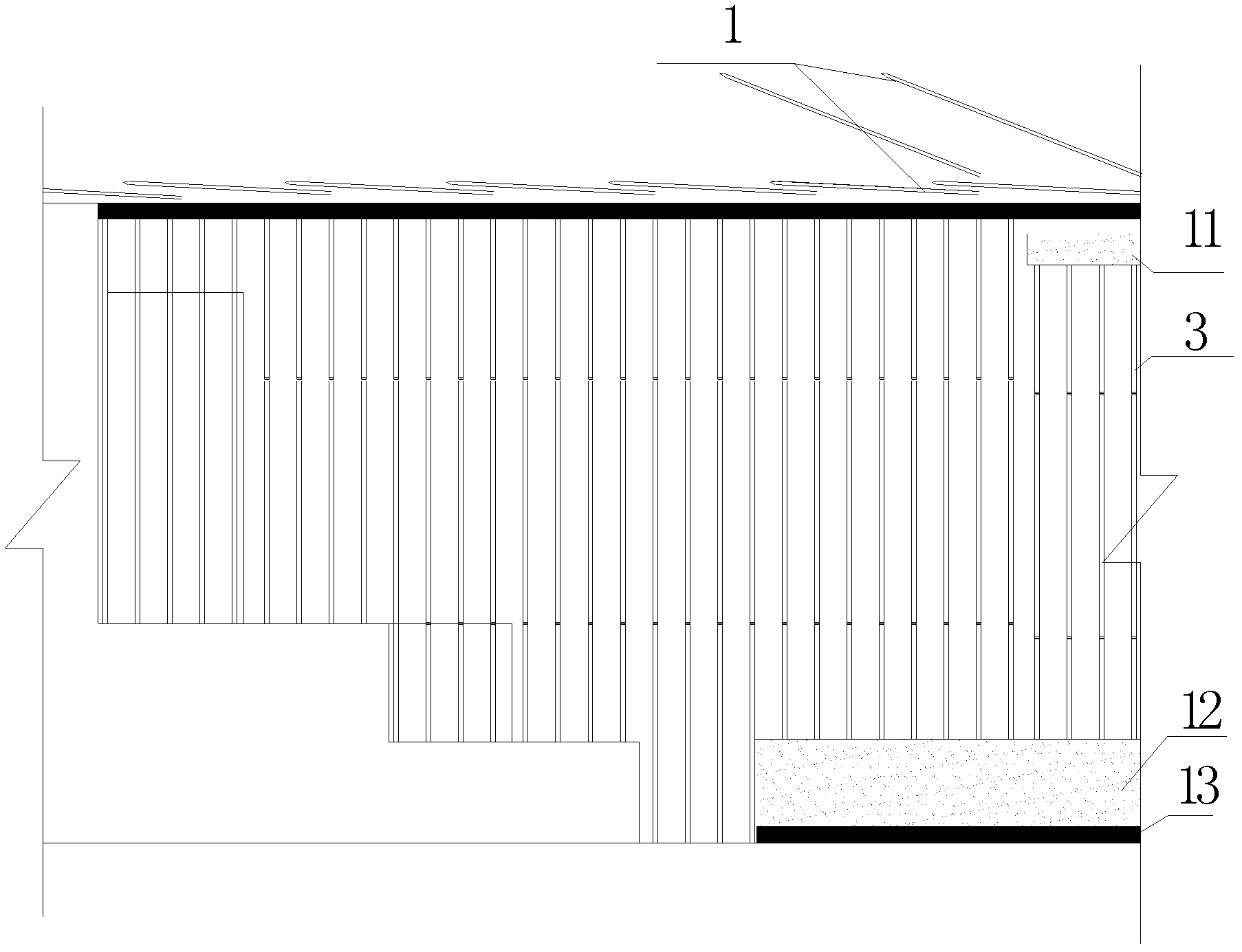

[0029] Such as figure 1 and figure 2 As shown, a kind of loess tunnel double-row small conduit rapid entry construction method of the present invention comprises the following steps:

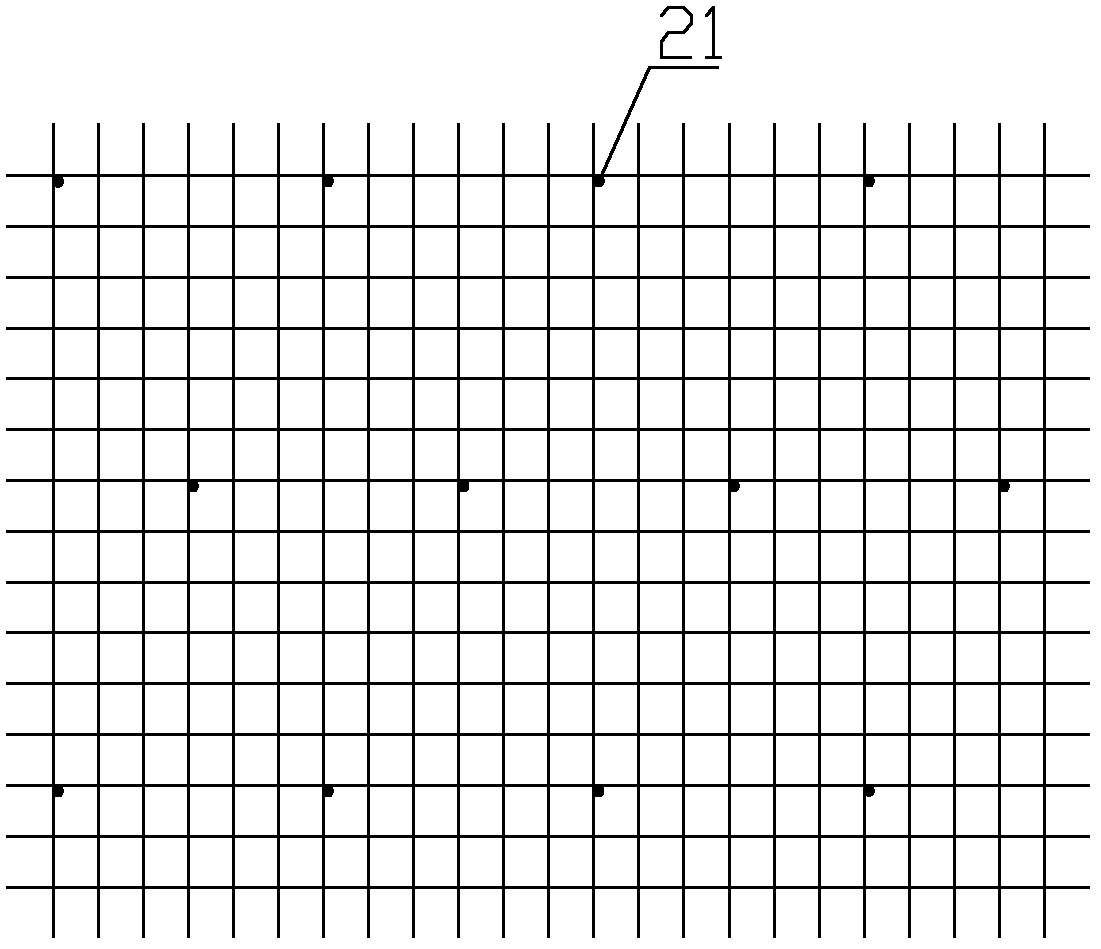

[0030] A. Excavation and support of the side slope. Immediately after the earthwork excavation of the side slope is completed, the temporary protection of the side slope is carried out with hanging net spraying and anchoring; the temporary protection of the side slope is carried out with Φ8 steel mesh, such as image 3 As shown, the grid spacing of the steel mesh is 20×20cm, the length of the charge anchor rod 21 is 4.5m, image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com