Fuel oil filtering system

A technology of fuel oil filtration and oil suction filter, which is applied in the direction of charging system, liquid fuel feeder, engine components, etc. It can solve the problems of low filtration precision, low filtration and water removal efficiency, etc., and achieve high filtration precision, filtration and High water removal efficiency and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

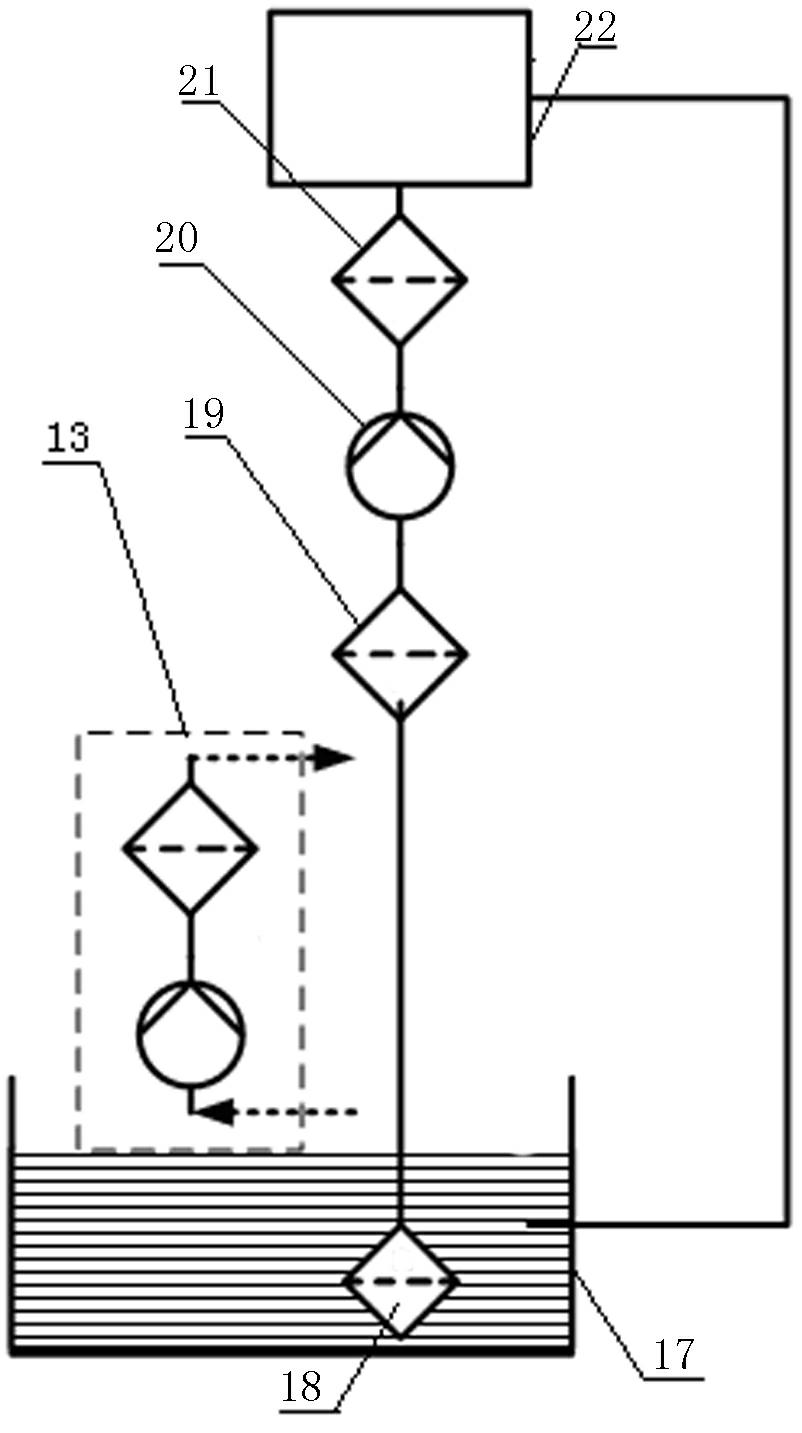

[0029] Embodiment 1: see Figure 4 , the fuel filter device 13 of the fuel filter system is connected in parallel between the oil suction filter 18 and the oil coarse filter 19, and the circuit of the combustion chamber 22 of the electronic fuel injection system is connected with the node between the fuel filter device 13 and the oil suction filter 18, and works The process is: the fuel in the fuel tank 17 is sucked into the fuel filter device 13 after passing through the oil suction filter 18, and the fuel filter device 13 intercepts and filters large particles, small particles, tiny particles and water in the fuel; A part of the finished fuel oil enters the coarse oil filter 19, and another part of the fuel oil is sucked away by the fuel filter device 13, and is filtered and purified again; the filter layer of the coarse oil filter 19 intercepts and filters large particles and moisture in the fuel oil; After the filtered fuel oil enters the fuel pump 20, it is pressurized an...

Embodiment 2

[0030] Example 2: see Figure 5, the oil inlet of the fuel filter device 13 of the fuel filter system is connected with the fuel tank 17, and the oil outlet is connected with the oil inlet of the coarse oil filter 19 and the circuit of the combustion chamber 22 of the EFI system. The specific working process is: The fuel in the tank 17 is sucked into the fuel filter device 13, and the fuel filter device 13 intercepts and filters large particles, small particles, tiny particles and water in the fuel; part of the fuel filtered by the fuel filter device 13 enters the oil coarse filter In 19, another part of the fuel returns to the fuel tank through the oil return pipeline; the filter layer of the coarse oil filter 19 intercepts and filters large particles and water in the fuel; after the coarsely filtered fuel enters the oil pump 20, it is pumped into the oil In the fine filter 21, the olein filter 21 intercepts and filters tiny particles in the fuel; the filtered fuel enters the...

Embodiment 3

[0031] Example 3, see Figure 6 , the oil inlet and outlet of the fuel filter device 13 of the fuel filter system communicate with the fuel tank 13 respectively. Large particles, small particles, tiny particles and moisture in the fuel; the fuel filtered by the fuel filter device 13 returns to the fuel tank 17, so that the fuel in the fuel tank 17 is repeatedly filtered in a short time; at the same time After the fuel oil in the fuel tank 17 passes through the oil suction filter 18, it is sucked in the oil coarse filter 19, and the filter layer of the oil coarse filter 19 intercepts and filters large particles and moisture in the fuel; the fuel oil after the coarse filtration enters the oil pump 20 Finally, it is pressurized and pumped into the olein filter 21, and the olein filter 21 intercepts and filters tiny particles in the fuel; the filtered fuel enters the combustion chamber 22 of the EFI system under the action of the pump pressure of the oil pump 20 to carry out Comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com