Automatic transmission shift quality improved via selective use of closed-loop pressure feedback control

A transmission, pressure technology, applied in the direction of transmission control, fluid-driven clutch, non-mechanical drive clutch, etc., can solve the adverse effects of operation changes, unexpected performance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

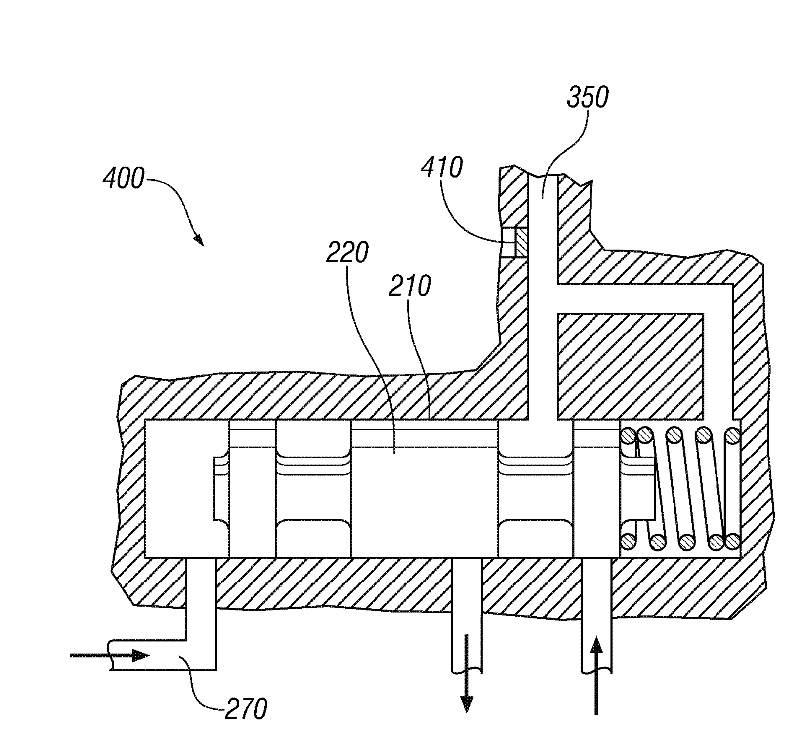

[0050] Referring now to the drawings, in which the figures are shown for the purpose of illustrating certain exemplary embodiments only and not for the purpose of limiting them, figure 1An exemplary clutch control system employing a modulating valve according to the present invention is schematically shown. Clutch control system 200 includes regulator valve 210 , pressure switch 240 , and hydraulic lines 270 , 272 , 274 , 276 , 278 , and 280 . Regulator valve 210 selectively controls the flow of pressurized hydraulic oil to and from hydraulically actuated clutches through movement of a selection mechanism (in the exemplary embodiment, spool valve plunger 220 ) within the regulator valve. The plunger 220 is selectively acted upon by the plunger's first end 222 and the plunger's second end 224, and the balance of forces determines the displacement position of the plunger within the regulator valve. The plunger 220 includes a plunger detail (or plunger detail) 226 (including hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com