Light guide plate and backlight module

A technology of backlight module and light guide plate, which is applied in the direction of optics, light guide, electric light source, etc., and can solve the problems of poor light source utilization rate of light guide plate, easy generation, and affecting the display quality of liquid crystal display devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The detailed description and technical content of the present invention will be described as follows with illustrations, but the accompanying illustrations are for illustration purposes only, and are not intended to limit the present invention.

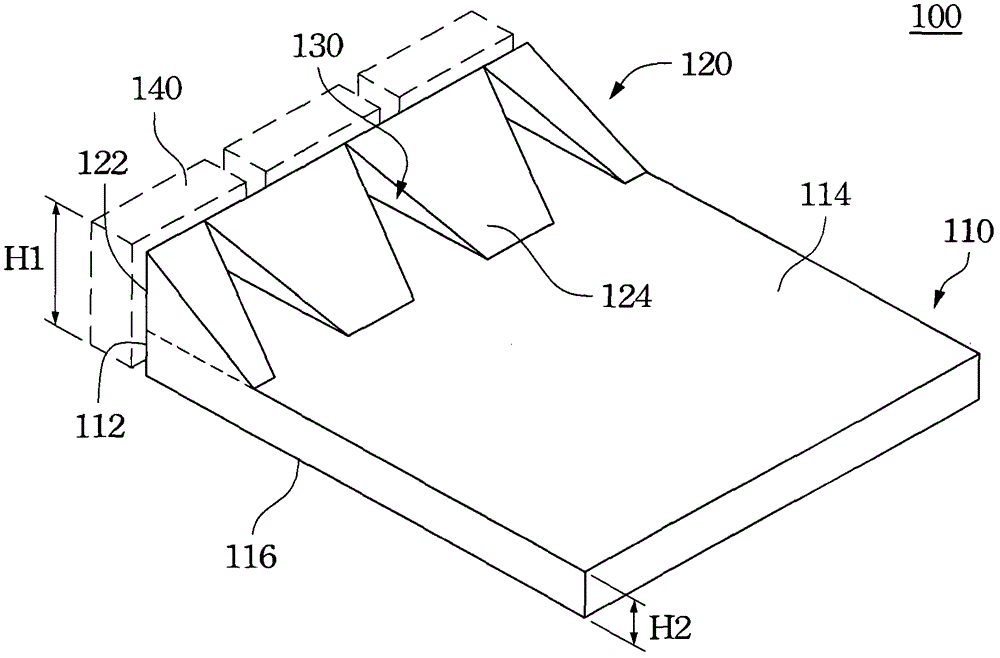

[0082] Please refer to figure 1 , is a three-dimensional schematic view of the first embodiment of the light guide plate of the present invention. The light guide plate 100 includes a light guide body portion 110 and an inclined light guide body 120 , wherein at least one groove 130 is formed between the inclined light guide bodies 120 . First, the light guide body 110 has a first light incident surface 112, a bottom surface 116 and a light exit surface 114. The first light incident surface 112 faces the light source 140 and receives the light emitted by the light source 140. The light source 140 of this embodiment A point light source (light emitting diode) is used as an example for illustration, but it can also be replaced by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com