Isolation type heat dissipation device of LED (light-emitting diode) lamp

A technology of LED lamps and cooling devices, which is applied in the direction of cooling/heating devices of lighting devices, lighting devices, components of lighting devices, etc., and can solve problems such as light decay, temperature rise of LED lamps, and failure to be effectively solved. To achieve the effect of improving work reliability, ensuring safety performance and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] In order to overcome a big problem of heat dissipation that has not been effectively solved in the existing LED lamps and the LED drive power supply on the LED lamps is installed in the radiator, the radiator is affected by the heating of electronic components and the safety problem of electrical insulation. The invention provides an isolated heat dissipation device for LED lamps. Reasonable structural measures are adopted for the isolated heat dissipation device for LED lamps, and the problems of electrical insulation and heat insulation are effectively solved.

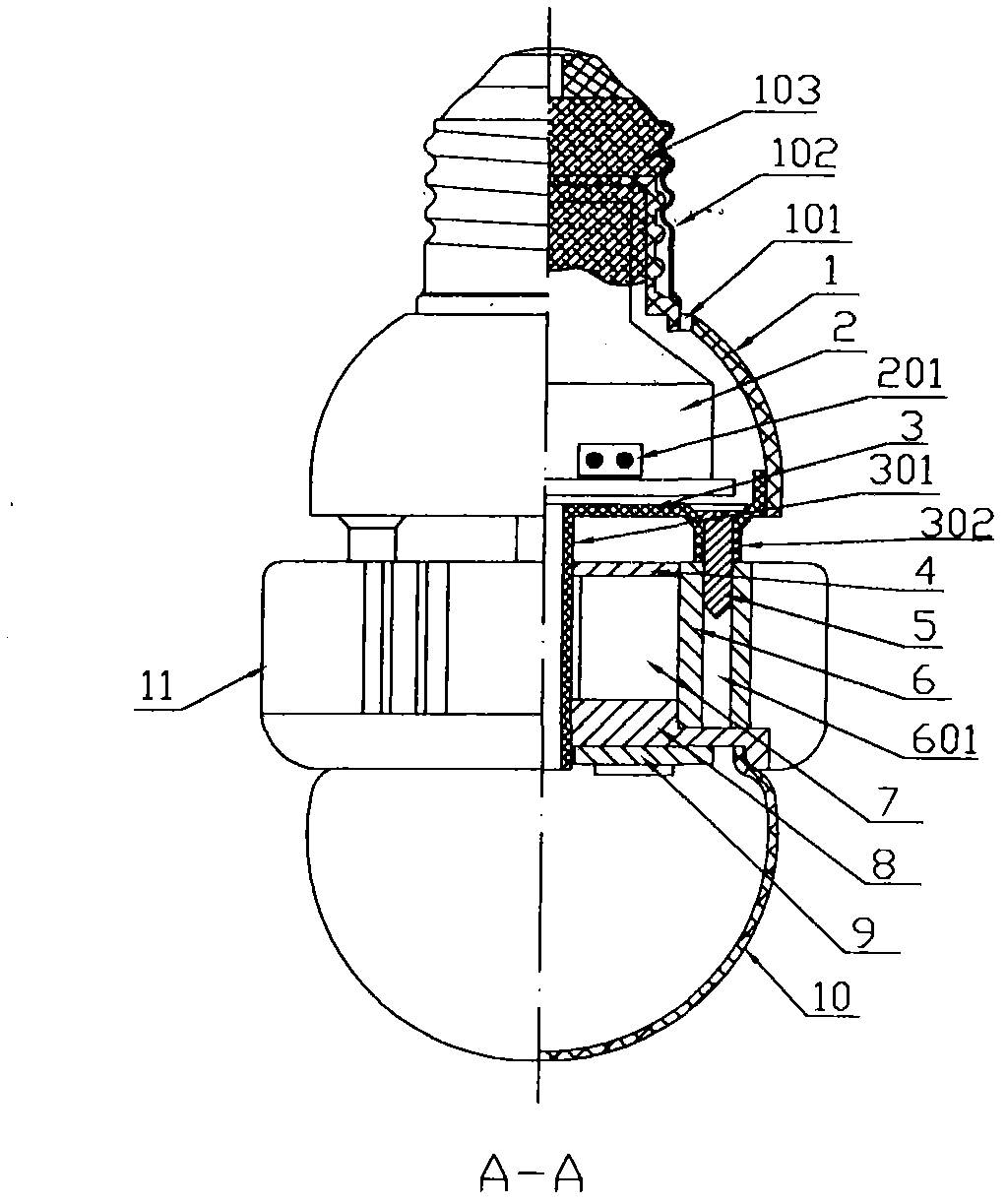

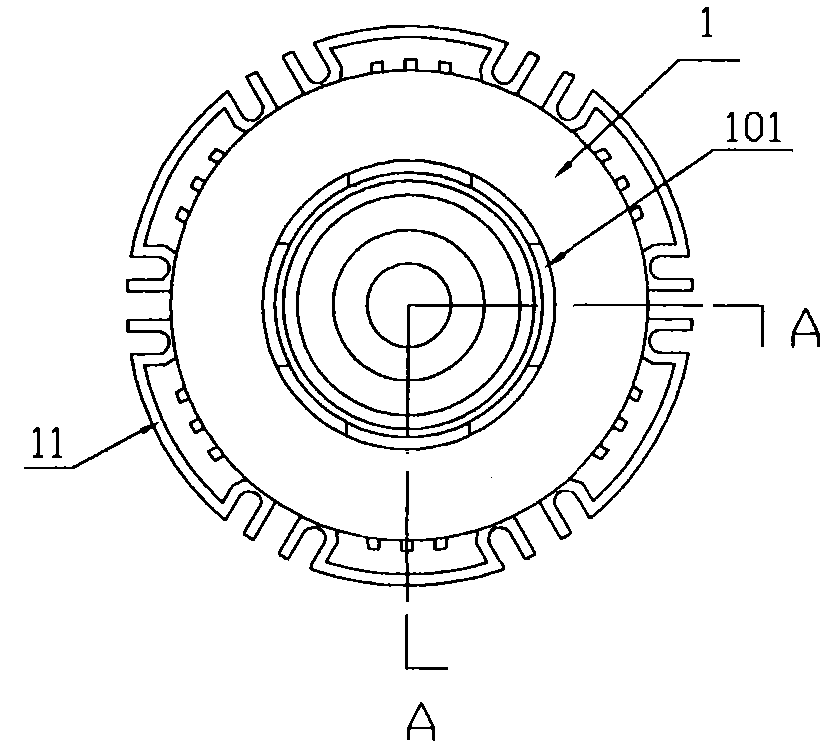

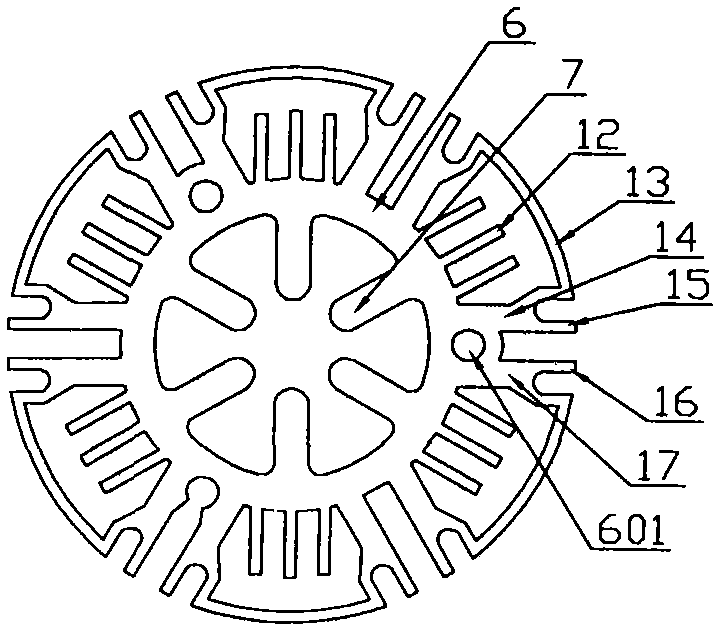

[0026] Depend on Figure 1 to Figure 6 As shown, the present invention includes an insulating lamp holder 1, an LED driver board 2, an isolation base 3, a column type heat sink 11, a heat transfer cylinder 6 and a heat transfer plate 8. When used for semiconductor lighting, the LED aluminum s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com