Large-caliber plane mirror surface-shaped detection device

A detection device and large-caliber technology, applied in the field of optics, to achieve low cost, good repeatability, and good test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

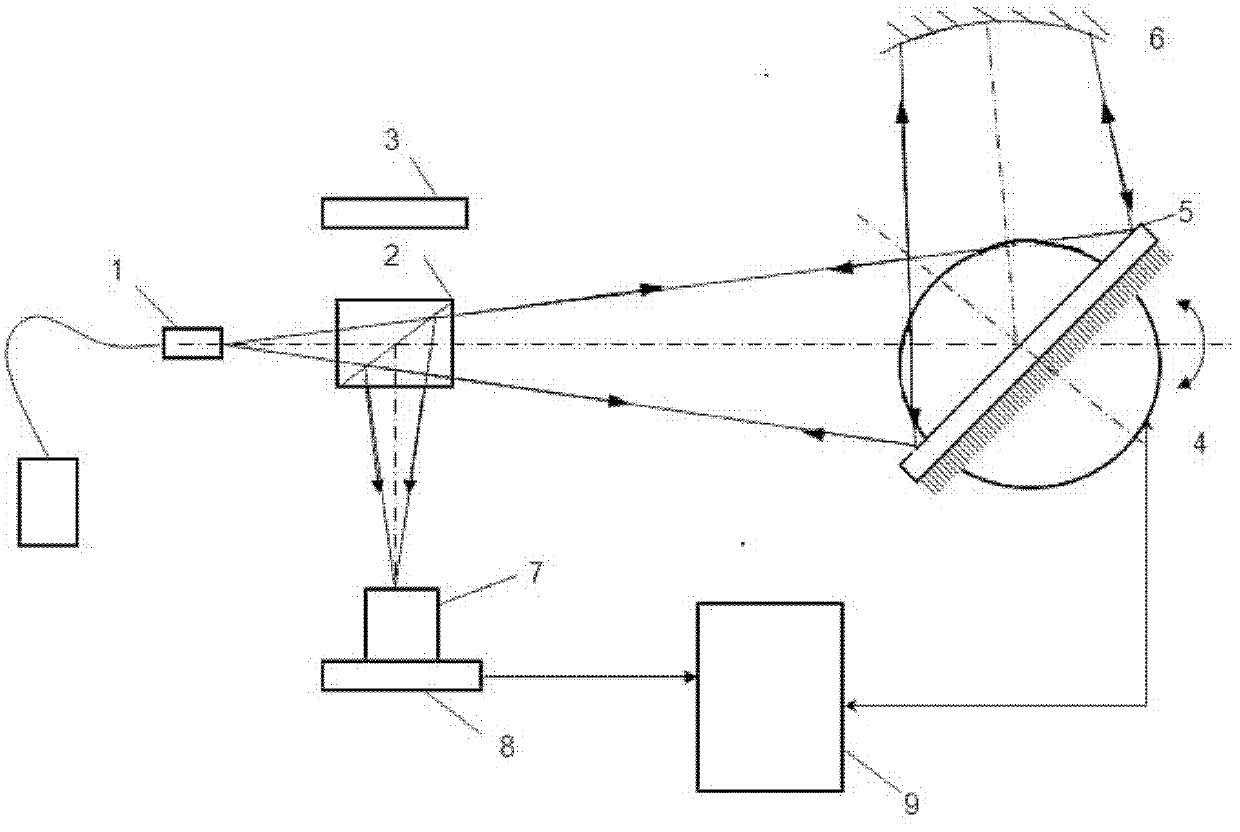

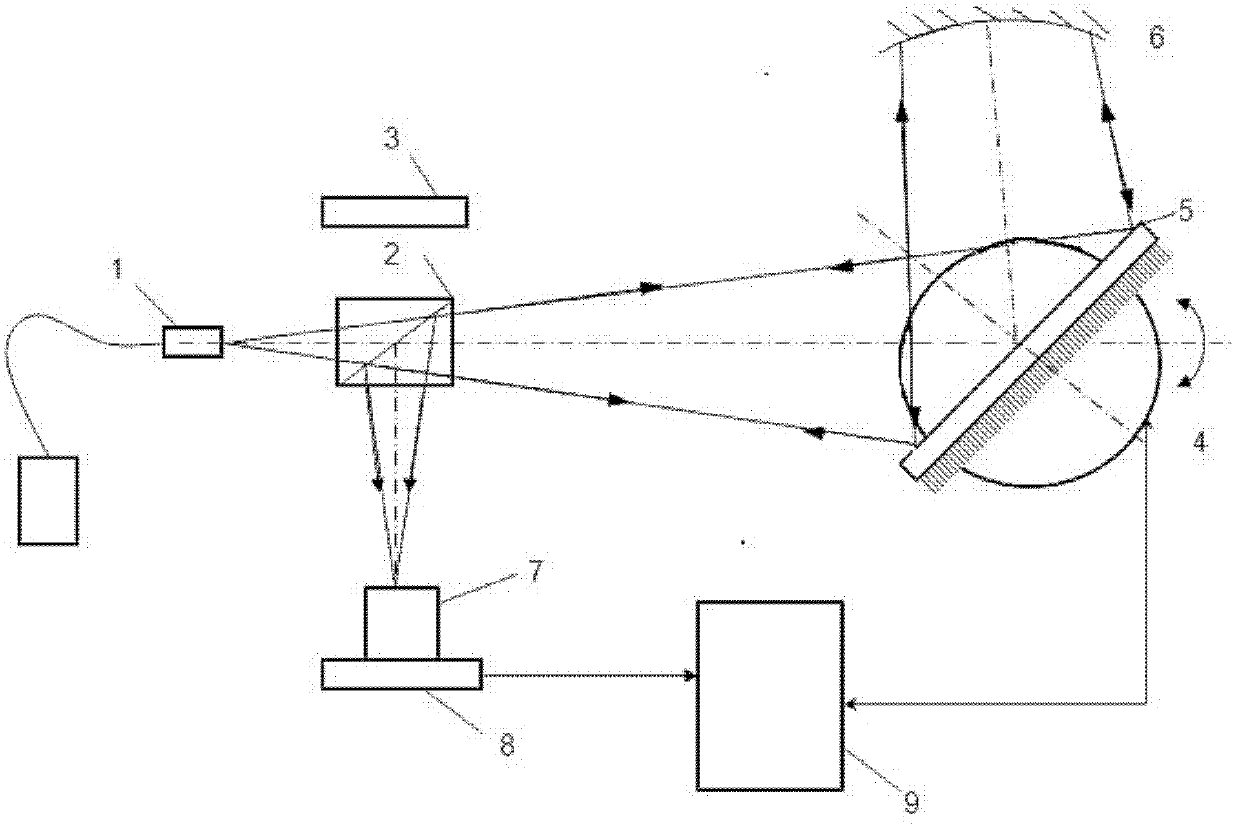

[0015] see figure 1 ,

[0016] Fiber laser 1, beam splitter 2, absorber 3, high-precision turntable 4, large-diameter plane mirror 5, standard spherical mirror 6, collimating lens 7, Hartmann wavefront sensor 8, control and acquisition computer 9. The beam splitter 2 is set on the outgoing light path of the fiber laser 1, and the beam splitter 2 divides the incident light incident on the beam splitter 2 into transmitted light and reflected light; the absorber 3 is set on the reflected light path after the beam splitter 2, absorbing the transmitted light The reflected light after the beam splitter 2 ensures the safety of testers; the standard spherical reflector 6 is set on the transmitted light path after the beam splitter 2; the standard spherical reflector 6 reflects the incident light incident on the standard spherical reflector 6 to the beam splitter mirror and reflected by the beam splitter 2 to the detection unit. The detection unit includes a collimator lens 7 and a H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com