Test method for improving appearance yield of GaN-based LED chip

A technology of LED chips and testing methods, applied in the field of optoelectronics, can solve problems such as increasing production costs, and achieve the effects of low cost, good testing accuracy and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Blue light chip GaN-based LED chip (COT state) test

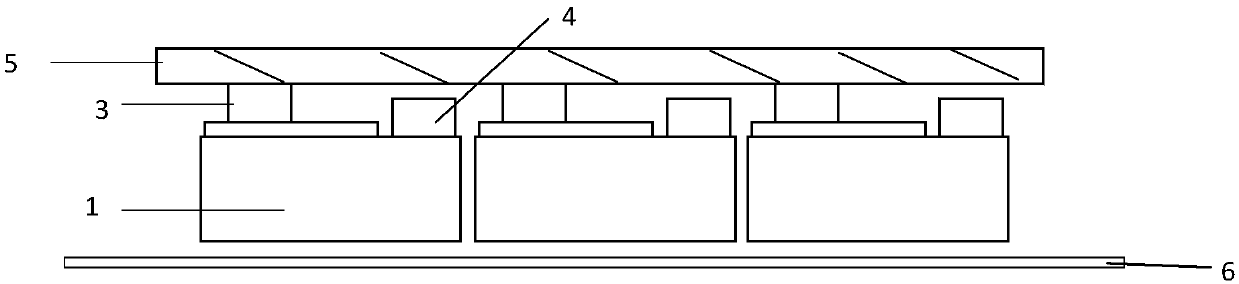

[0035] (1) Blu-ray chip GaN-based LED chip, the P / N electrode spacing of the chip is 25 μm, and the chip is covered with an anisotropic conductive film. The light transmittance of the anisotropic conductive film is about 70%, and the thickness is 1mm. membrane, the spacing between chips is 200µm, as figure 1 shown;

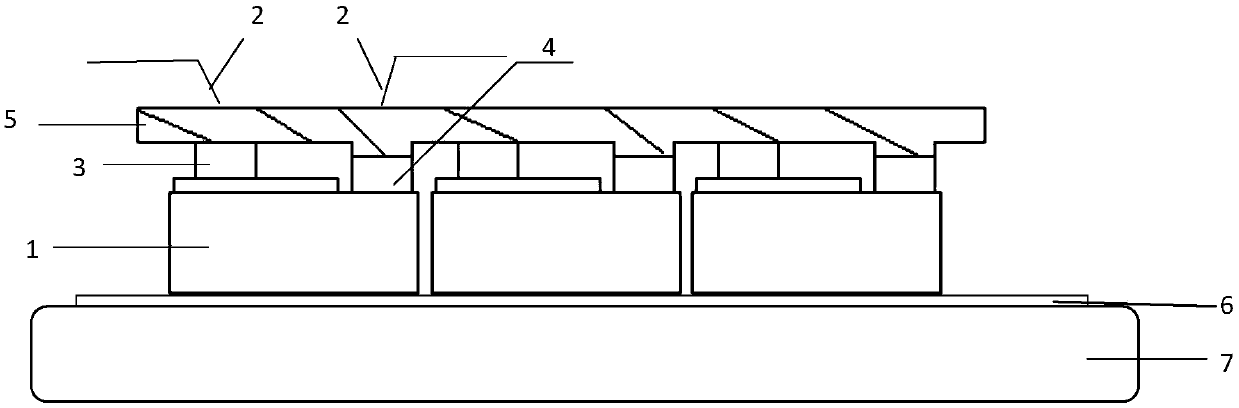

[0036] (2) Place the product to be tested in step (1) on the test machine platform, and use the test machine platform to heat the anisotropic conductive film at a temperature of 100°C for 8 minutes, such as figure 2 shown;

[0037] (3) Scan the LED chip covered with the anisotropic conductive film on the automatic testing machine. After the test system completes the image recognition, stick the two probes of the testing machine to the anisotropic conductive film area corresponding to the positive and negative electrodes of the chip. Adjust the test needle pressure so that the strength ...

Embodiment 2

[0040] Embodiment 2: GaN-based LED chip (COW state) test,

[0041] (1) Blue light GaN-based LED chip, the P / N electrode spacing of the chip is 30 μm, and the chip is covered with an anisotropic conductive film. The light transmittance of the anisotropic conductive film is about 70%, and the thickness is 2mm. The chip is placed on the blue film On, the spacing between chips is 15-20μm;

[0042] (2) Place the product to be tested in step (1) on the test machine platform, and use the test machine platform to heat the anisotropic conductive film at a temperature of 110°C for 9 minutes;

[0043] (3) Scan the LED chip covered with the anisotropic conductive film on the automatic testing machine. After the test system completes the image recognition, stick the two probes of the testing machine to the anisotropic conductive film area corresponding to the positive and negative electrodes of the chip. Adjust the test needle pressure so that the strength of the needle pressure achieves ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com