Sheet type common-mode choke row

A common mode choke and choke technology, applied in the field of chip common mode choke, can solve the problems of many electrode layers, low impedance peak frequency, etc., to simplify the process, high frequency range, reduce product cracking the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

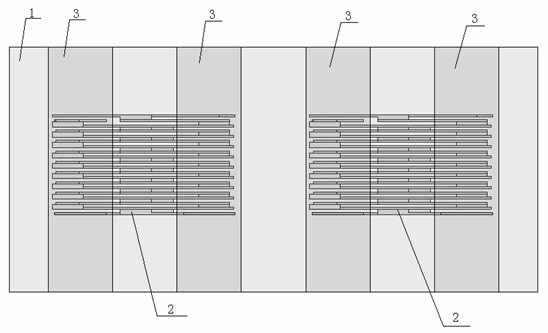

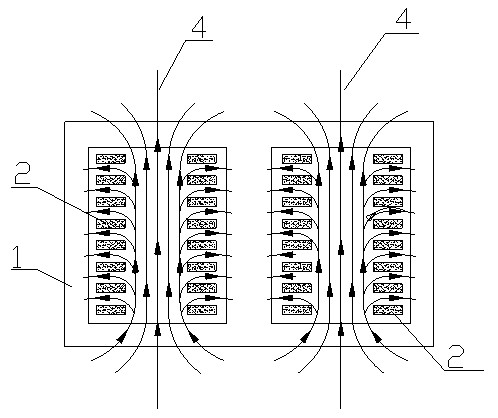

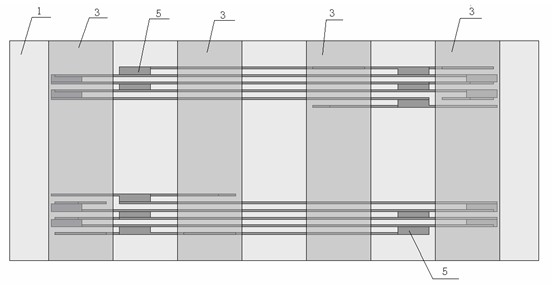

[0031] A chip common-mode choke row, comprising an upper substrate layer, a lower substrate layer, and at least two stacked common-mode chokes comprising coil layers with conductive coil patterns stacked between the upper substrate layer and the lower substrate layer The chokes are separated by the intermediate substrate layer between the upper and lower adjacent common mode chokes.

[0032] Such as Figure 3~7-5 As shown, the common mode choke row of this embodiment is in the form of a rectangular parallelepiped as a whole, including two chip common mode chokes, one of which (the upper coil) is located between the upper substrate layer 7 and the middle substrate layer 8, and the other The (lower coil) is located between the middle substrate layer and the lower substrate layer 9, and the common mode choke includes a multilay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com