Disc rotation type four-fracture vacuum arc extinguishing chamber

A vacuum interrupter, rotary type technology, applied in the direction of high-voltage air circuit breakers, electrical components, electric switches, etc., can solve the problem of service life, safety, operation reliability reduction, operating mechanism requires complex operating mechanism, and breaking synchronization The performance does not meet the technical requirements and other problems, so as to achieve the effect of convenient operation, overhaul and maintenance, reduction of moving parts, and improvement of stability and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

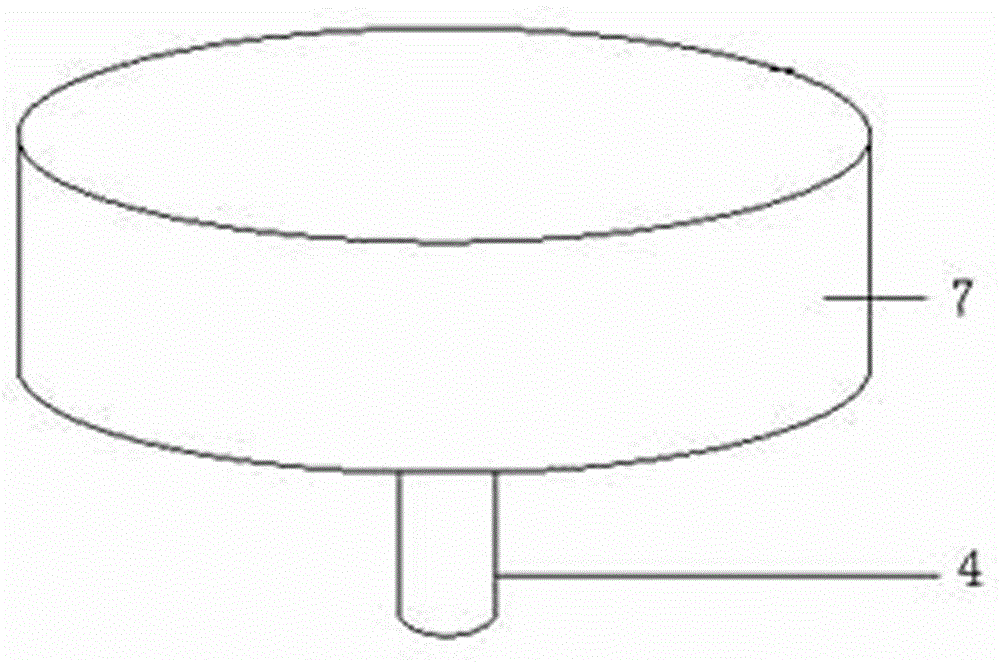

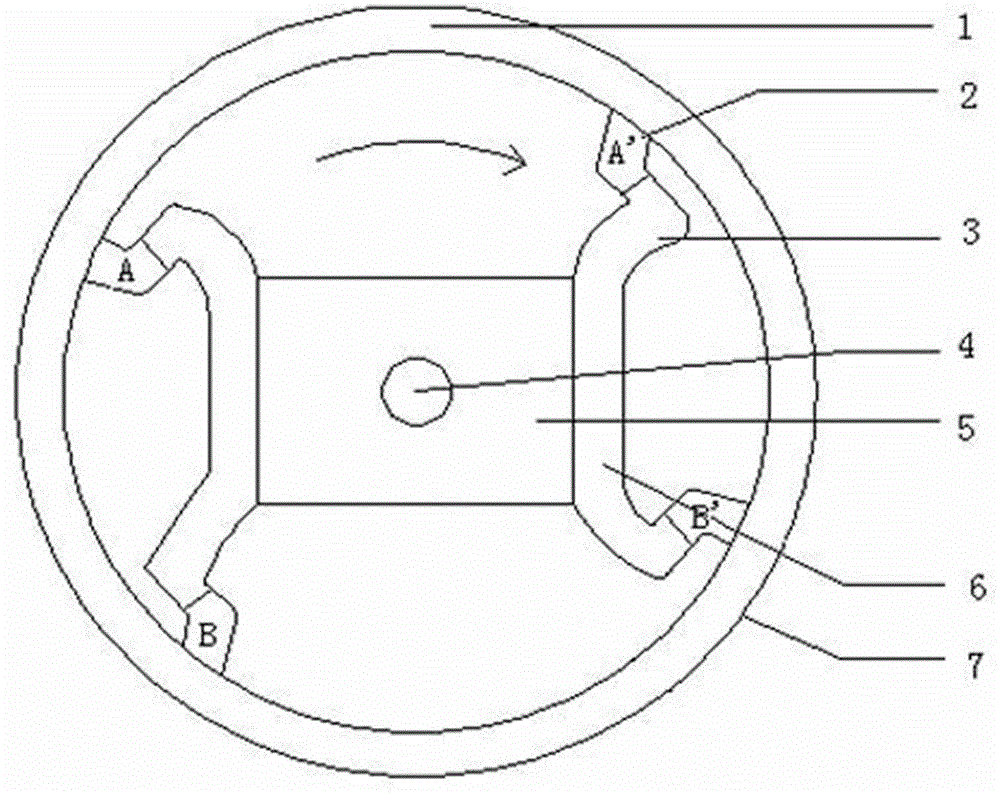

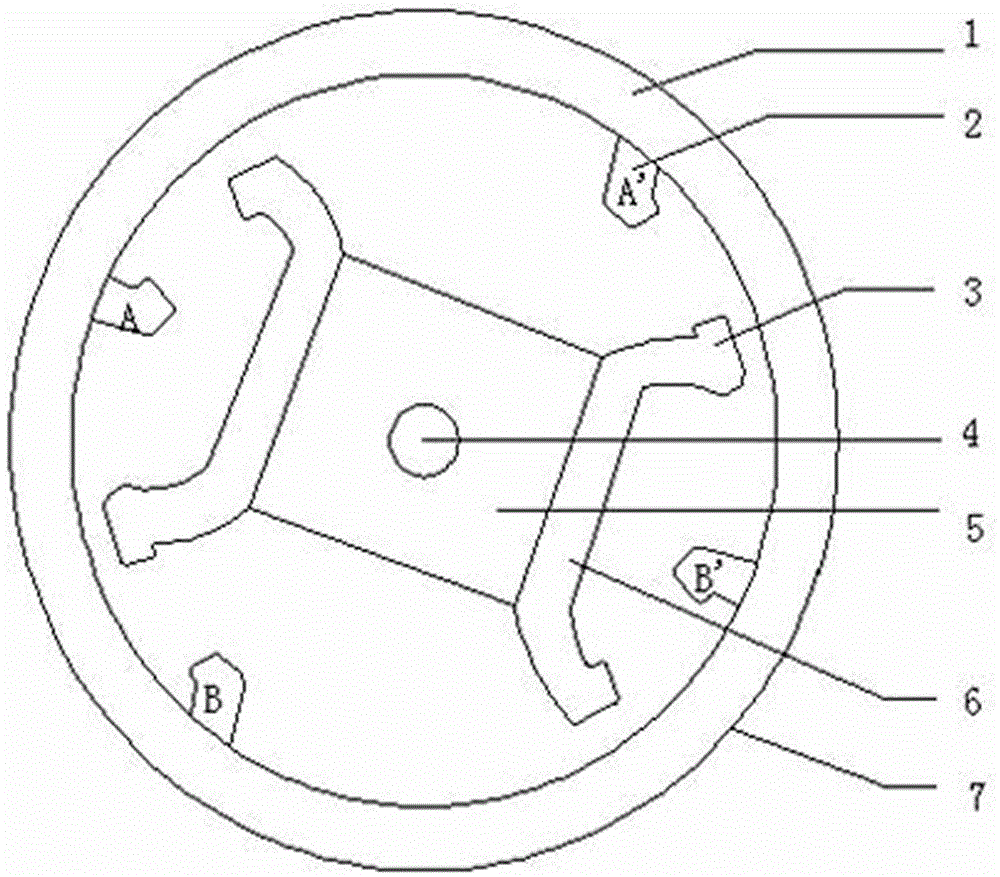

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is described in more detail: as Figure 1 ~ Figure 3 As shown, the disc-type rotating four-break vacuum interrupter provided by the present invention includes a disc-type rotating four-break vacuum interrupter 7 connected to the insulating shaft 4 and a disc-type rotating four-break vacuum interrupter 7 7. For the static contact 2 and the moving contact 3 inside, one end of the insulating shaft 4 is connected to the external drive motor or rotating equipment, and the other end of the insulating shaft 4 extends into the disc-type rotary four-fracture vacuum interrupter 7 and connects with the The insulating disks 5 with conductor connecting rods 6 at both ends are connected, the moving contact 3 is arranged on the end faces of the conductor connecting rods 6 at both ends of the insulating disk 5, and the static contact 2 is arranged on the four On the insulating outer wall 1 of the fractu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com