Epitaxial substrate, semiconductor light emitting element using the same and manufacturing process

A technology for epitaxial substrates and light-emitting elements, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high manufacturing cost and slow production speed, and achieve low manufacturing cost, fast production, and excellent photoelectric efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

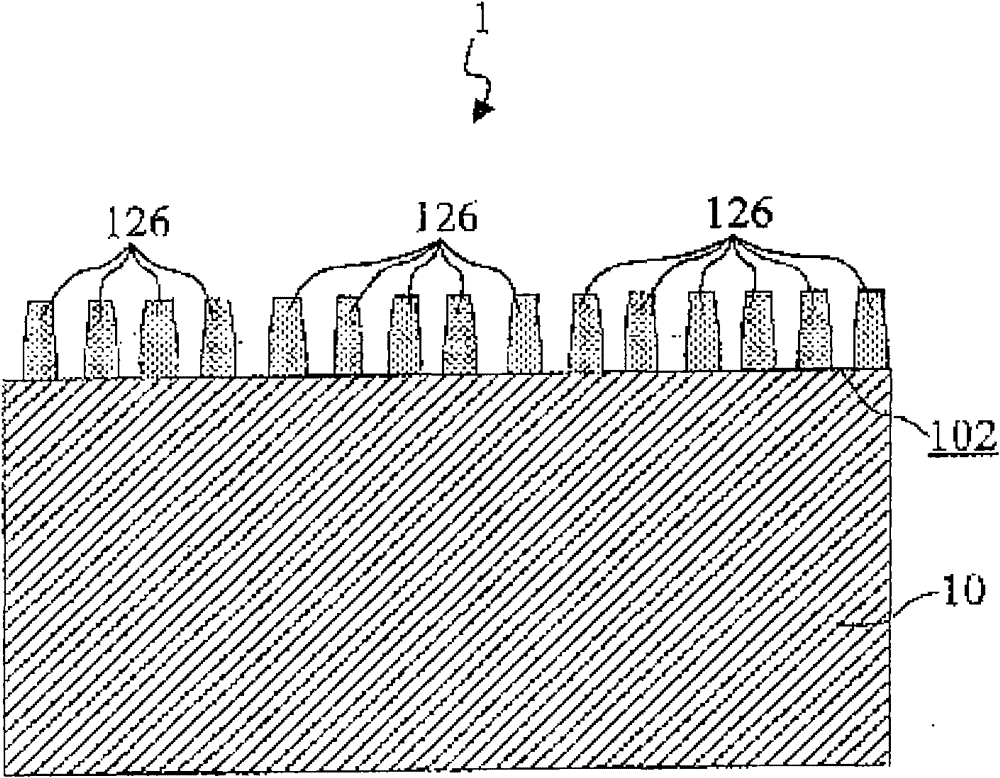

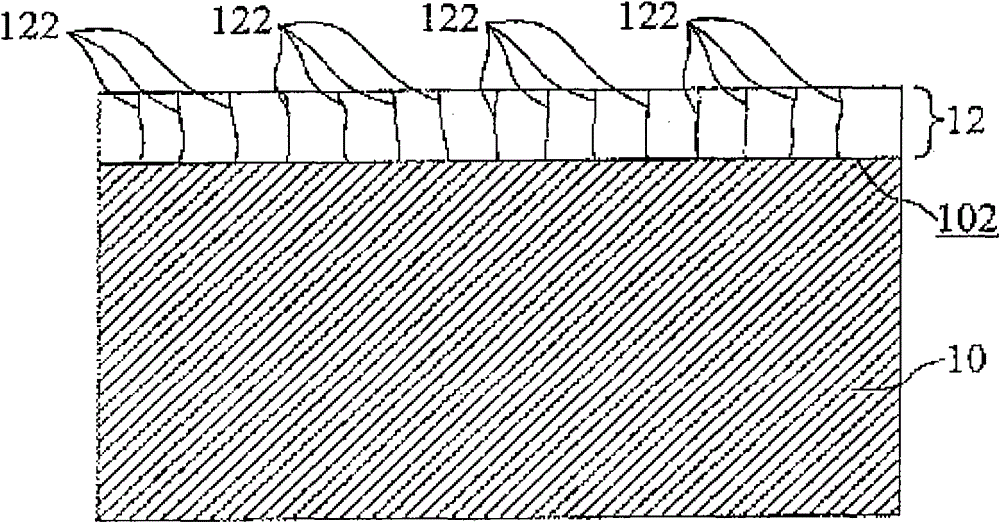

[0035] see figure 1 , figure 1 It is schematically drawn in a cross-sectional view on an epitaxial substrate 1 according to a preferred embodiment of the present invention. The epitaxy base 1 can be used for the epitaxy of a compound semiconductor material, for example, III-V compounds such as gallium nitride, aluminum gallium nitride, aluminum indium gallium nitride, or cadmium telluride, zinc oxide, zinc sulfide, etc. II-VI compounds.

[0036] Such as figure 1 As shown, the epitaxial substrate 1 according to the present invention includes a crystal substrate 10 . The crystal substrate 10 has a crystal surface 102 .

[0037] In particular, a plurality of nanoscale pillars 126 are randomly arranged on the crystal surface 102 of the crystal substrate 10 . The plurality of nanoscale pillars 126 are formed by an oxide of a second material, and the second material is different from the first material. It should be noted that the surface of the epitaxial substrate 1 according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com