Concentric-circle vacuum photo-thermal photoelectric conversion glass tube

A technology of photothermal photoelectricity and concentric circles, which is applied in the field of solar energy utilization, can solve the problems of inability to use photothermal conversion, damage to glass tubes in harsh environments, and great influence on photoelectric conversion efficiency, so as to avoid the influence of photoelectric conversion efficiency and accelerate its promotion The effect of speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

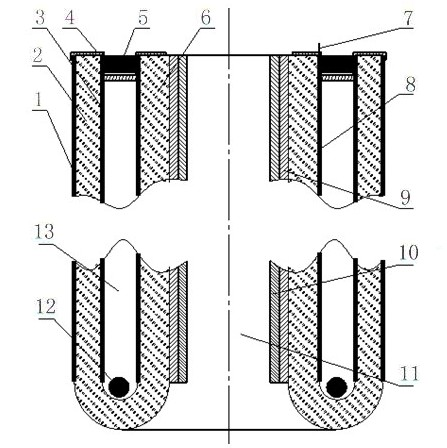

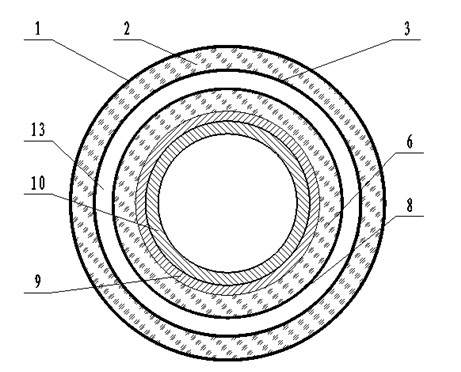

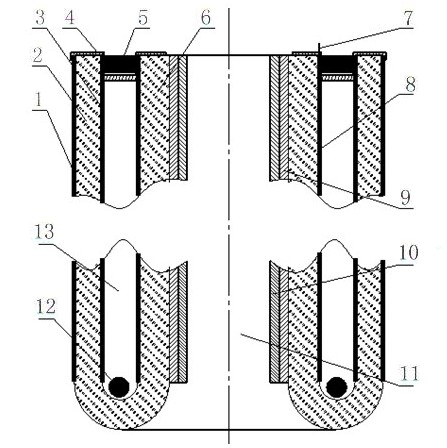

[0020] The concentric vacuum photothermal photoelectric conversion glass tube consists of an outer glass tube 1, an inner glass tube 6, two layers of anti-reflection coatings 1 and 3, a photoelectric conversion layer 8, a photothermal conversion layer 9, a heat conduction layer 10, and a sealing solder 5 , support frame 4, getter 12 etc. constitute. Sunlight irradiates the photoelectric conversion layer and the photothermal conversion layer through the outer glass tube, the photoelectric conversion layer converts sunlight into electrical energy, and the photothermal conversion layer converts sunlight into thermal energy.

[0021] The inner and outer glass tubes are tempered or semi-tempered high thermal resistance soda-lime glass tubes with a wall thickness of 4mm. Clean the glass tubes 2 and 6 thoroughly with deionized water and place them in a dryer for drying. Be careful not to touch any pollutants during this period. After the glass tube is dried, coat the anti-reflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com