Method for utilizing base metal catalytic ink to manufacture printed circuit

A technology for catalyzing inks and printed circuits, applied to printed circuit components, inks, metal pattern materials, etc., can solve problems such as high costs, and achieve the effects of reduced manufacturing costs, good electrical conductivity, and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] Embodiment: A kind of method that utilizes base metal catalytic ink to make printed circuit

[0088] The base metal catalytic ink is uniformly formed by stirring and mixing raw materials in a certain proportion.

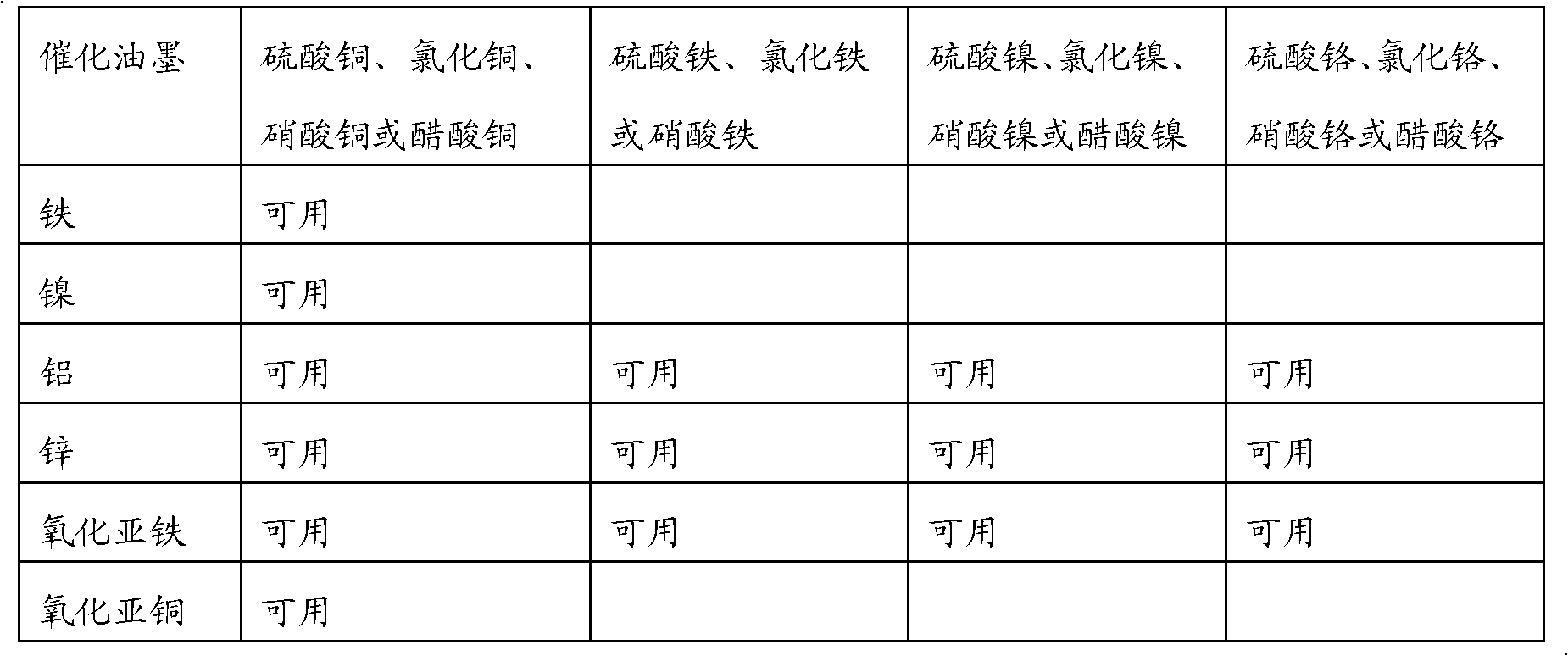

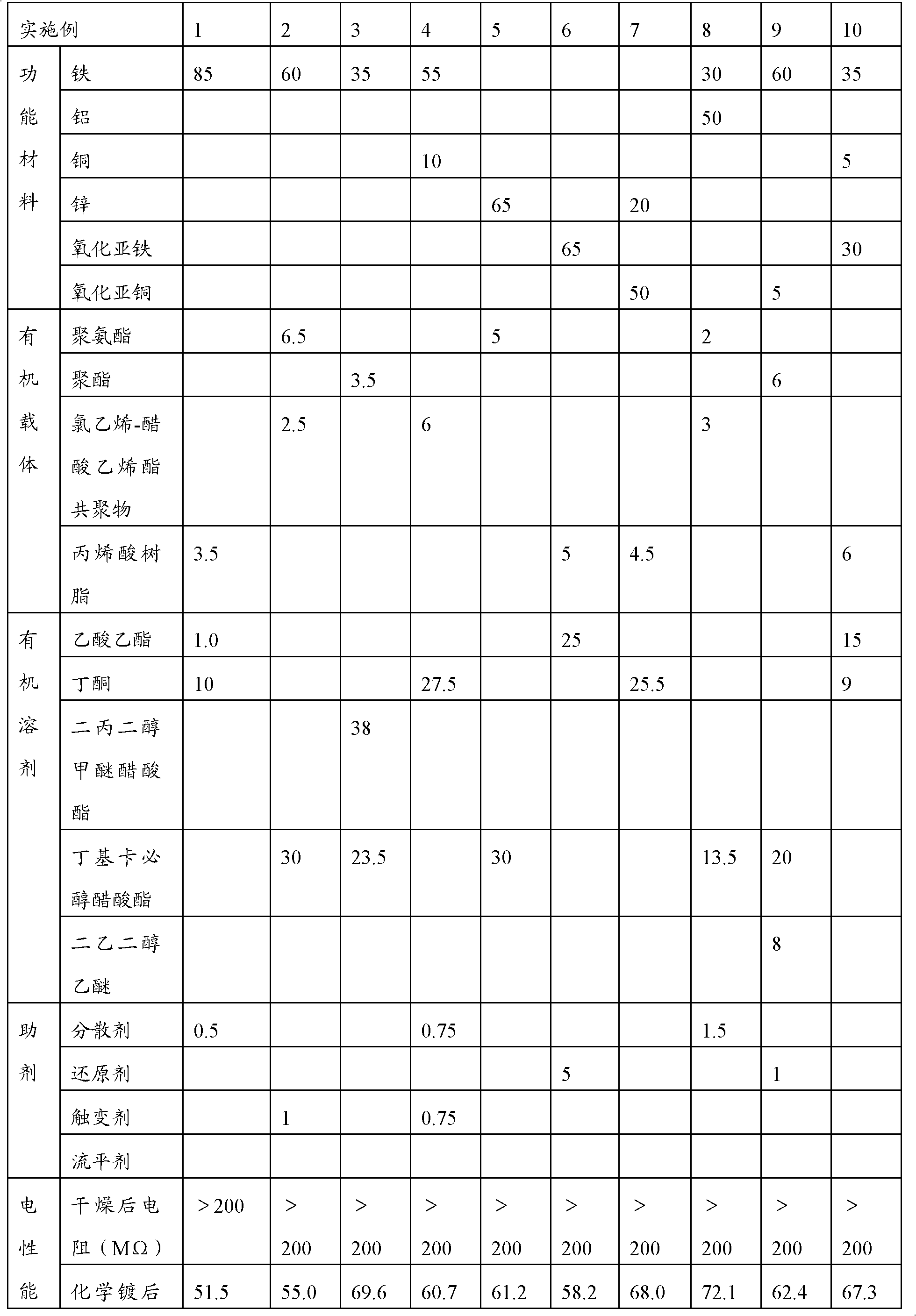

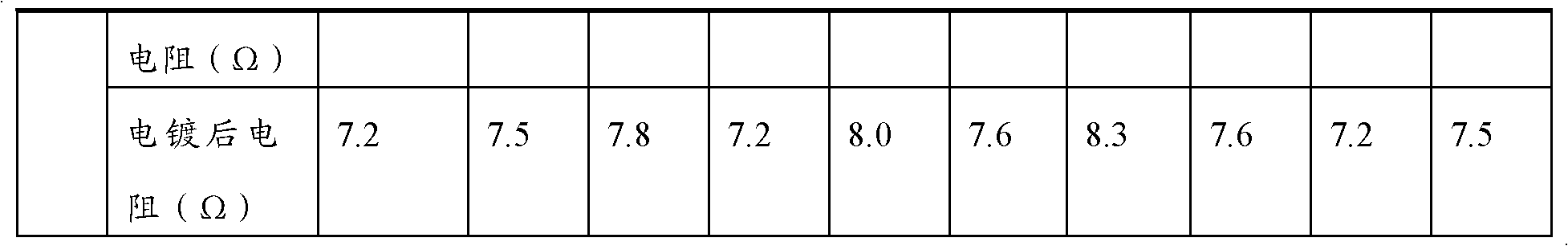

[0089] Table 2: be the raw material formula (numerical unit: weight %) of embodiment 1~10 base metal catalytic printing ink

[0090]

[0091]

[0092] Embodiments 1-10 The method for making printed circuit: According to the raw material formula in Table 2, first dissolve the organic carrier in the organic solvent, then add functional materials and additives, fully stir and disperse evenly, and obtain the base metal catalytic ink.

[0093] When making a printed circuit, use the screen printing method to print a base metal catalytic ink circuit with a width of 0.4 mm and a length of 1 meter on the PET film, then put it in a 150-degree oven to dry for 60 minutes, and then perform electroless plating: put the dried item Put it into a copper sulfate solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com