Method for producing simple training pant and device for processing the same

A technology of processing device and training pants, applied in clothing, underwear, baby underwear and other directions, can solve the problems of high production cost of equipment and products, complex combination structure, low production efficiency, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A method for producing simple training pants and a processing device thereof, characterized in that,

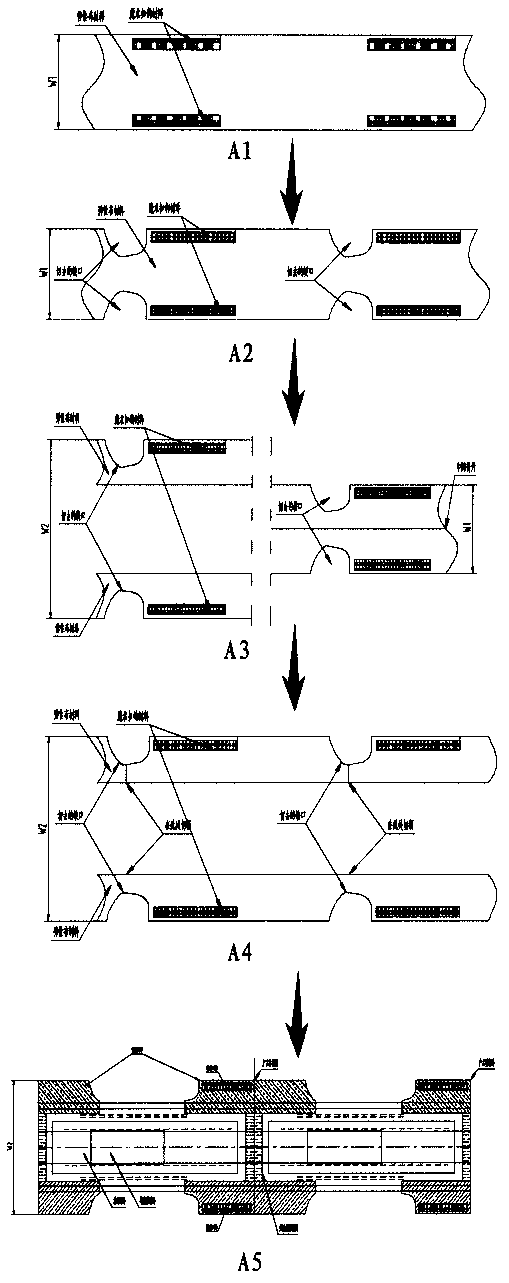

[0030] Such as figure 1 As shown, the described method for producing simple training pants specifically includes the following processing steps:

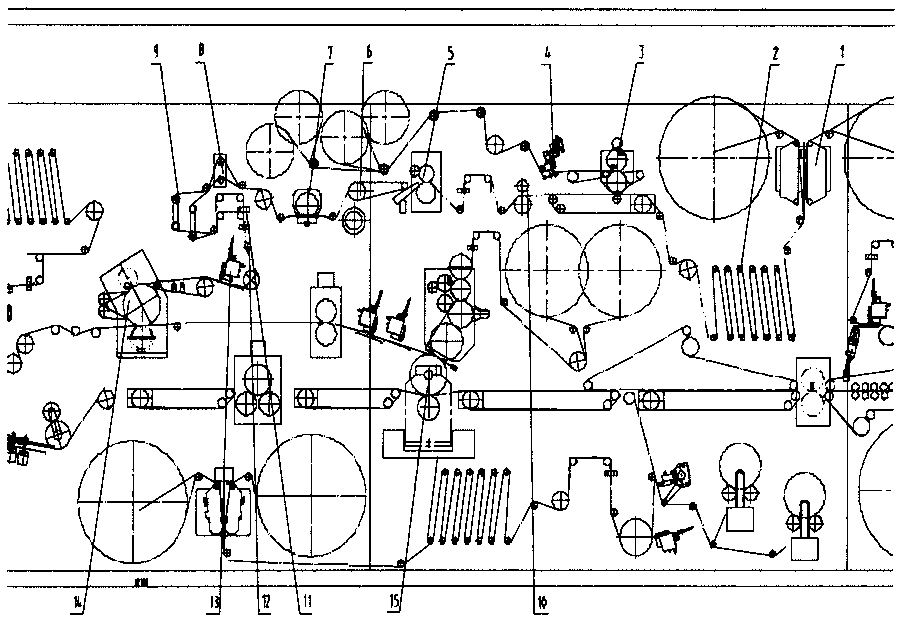

[0031] Step 1, the elastic cloth material shearing type automatic material change mechanism 1 and the tension storage mechanism 2 replace the material roll without stopping the machine, and the detection material connection head is discharged from the reject port of the production line; as shown in A1, the magic The clasp material enters the magic clasp hook strip absorption traction, cutting, transfer and sticking device 3 after being glued by the magic clasp hook strip gluing mechanism 4, and is periodically bonded with the elastic cloth material in sections;

[0032] Step 2, as shown in A2, the elastic cloth material behind the composite hook and loop is cut out a gap of a certain shape through the elastic material arc c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com