Dry purification system for agriculture and forest biomass gasified gas

A purification system and biomass technology, applied in the direction of climate change adaptation, climate sustainability, human health protection, etc., can solve the problems of secondary pollution of extraction liquid, affect the quality of tar and extraction liquid, and have not been widely promoted. The effect of system composition science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

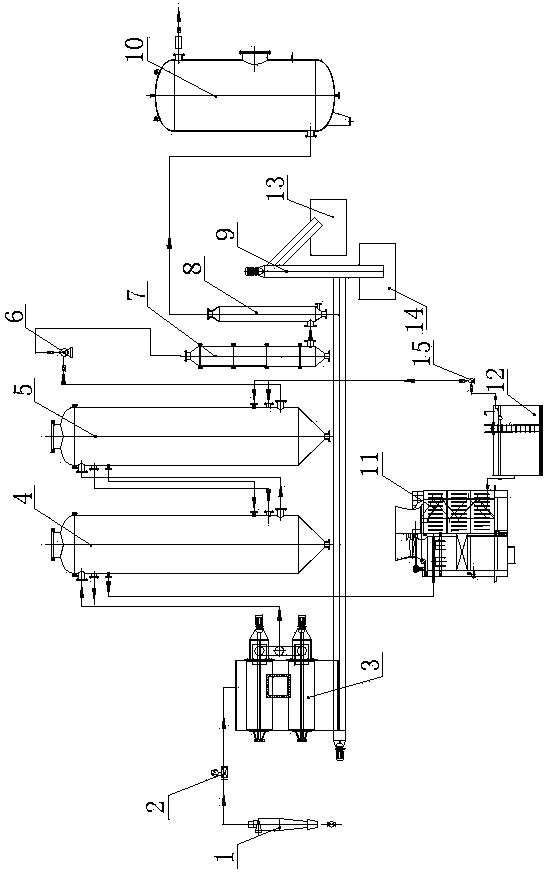

[0011] Control attached figure 1 Its structure includes a dust removal and coking system, a condensation separation system, a purification and drying system, and a tar moisture collection and separation system, wherein the fine powder separator 1 in the dust removal and coking system is connected to the centrifugal dust removal and coking machine 3 through an intermediate electric valve 2, The condensation separation system consists of A high-efficiency condenser 4 and B high-efficiency condenser 5. Two-stage high-efficiency condensers are connected in series. The induced draft fan is placed between the condensation separation system and the purification and drying system. The purification and drying system is connected together through the purification tower 7 and the dryer 8. The tar water collection and separation system separates the collected tar pool 13 and the coke water pool 14 through two spirals.

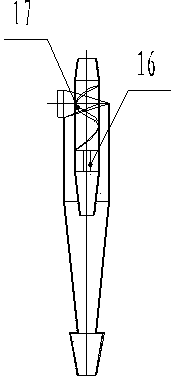

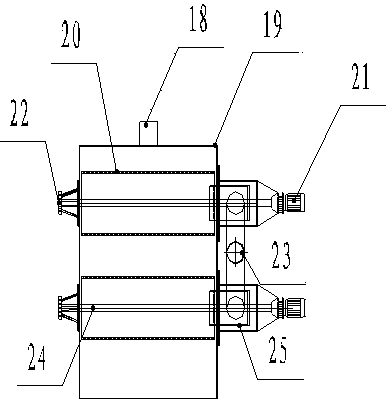

[0012] The structure of the dedusting and decoking system is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com