Micro-reaction device and application thereof in synthesis of glycidyl methacrylate

A methacrylic acid and micro-reaction technology, which is applied in chemical/physical/physicochemical processes, chemical instruments and methods, organic chemistry, etc., can solve problems such as inability to continue production, difficulty in process amplification, and long reaction time, so as to avoid Reaction time, convenient and safe operation, and improved synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

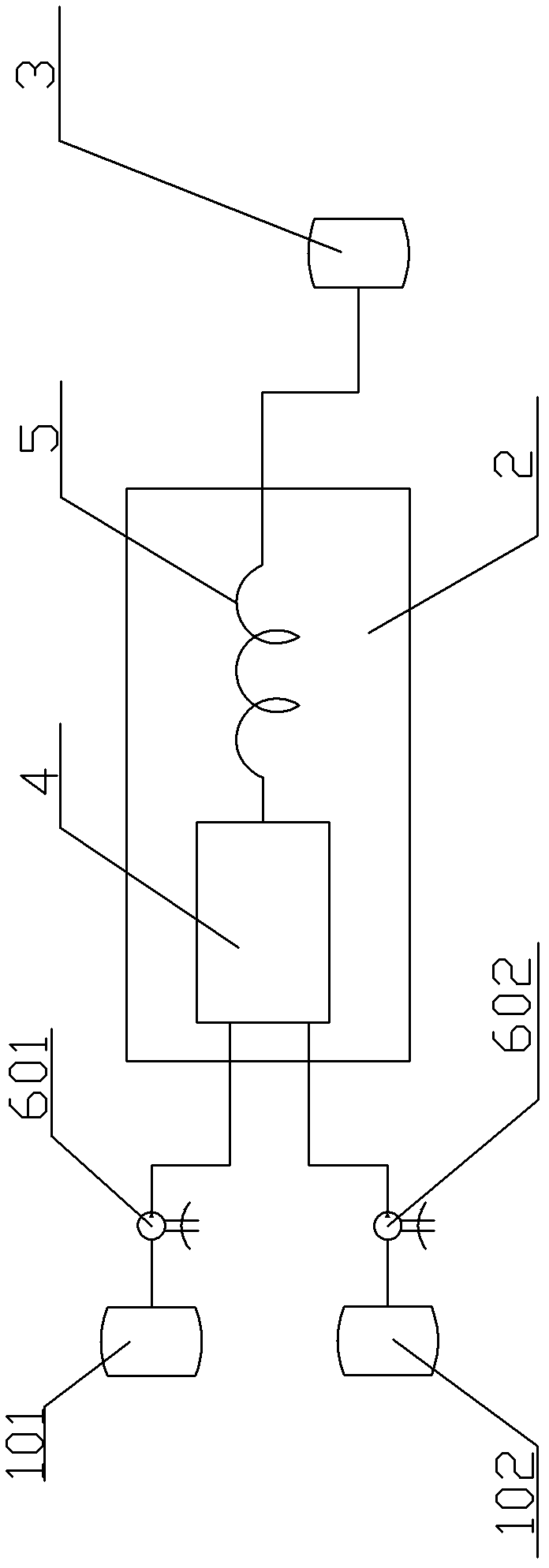

[0039] The present invention combines the attached figure 1 to explain. The feed tank I101 of the micro-reaction equipment is connected to the micro-mixer 4 through the constant flow pump I601, the feed tank II102 is connected to the micro-mixer 4 through the constant-flow pump II602, and the other side of the micro-mixer 4 is connected to the delay reaction channel 5 It is connected with the discharge tank 3; the micro-mixer 4 and the delay reaction channel 5 are fixed in the constant temperature oil bath 2. The delay reaction channel 5 has a diameter of 3.175mm and a length of 2m, and its material is stainless steel. The channel diameter of the micro-mixer 4 is 50 μm.

Embodiment 2

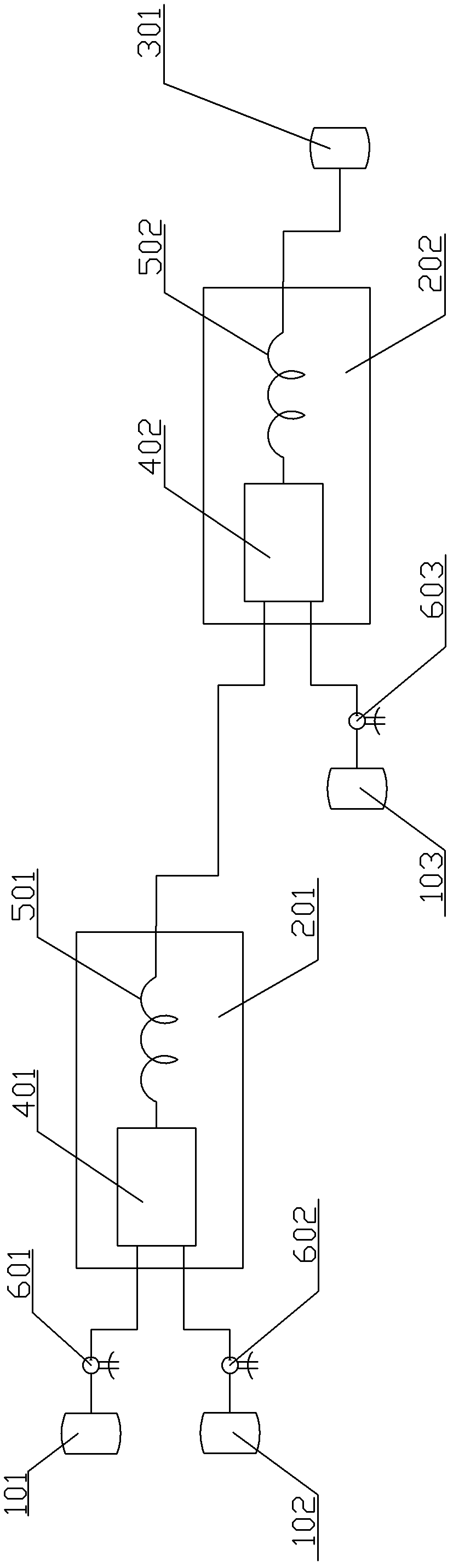

[0041] The present invention combines the attached figure 2to explain. The feeding tank I101 of the micro-reaction equipment is connected to the micro-mixer I401 through the constant flow pump I601, the feeding tank II102 is connected to the micro-mixer I401 through the constant-flow pump II602, and the other side of the micro-mixer I401 is connected to the delay reaction channel I501 Link to each other with micro-mixer II402, micro-mixer I401 and delay reaction channel I501 are fixed in constant temperature oil bath tank I201; Described feed tank III103 links to each other with micro-mixer II402 through constant-flow pump III603, another part of micro-mixer II402 One side is connected to the receiver 301 through the delayed reaction channel II502, and the micro-mixer II402 and the delayed reaction channel II502 are fixed in the constant temperature oil bath II202. The delay reaction channel 5 has a diameter of 3.175mm and a length of 2m, and its material is stainless steel. ...

Embodiment 3

[0043] The micro reaction equipment of Example 1 was used to synthesize glycidyl methacrylate. Specific steps are as follows:

[0044] ①Ring-opening esterification reaction:

[0045] Use absolute ethanol to calibrate the micro-reaction equipment; pass through absolute ethanol to flush the pipeline to check whether there is any leakage in the pipeline; mix 455g of methacrylic acid solution, 7.63g of urotropine and 3.30g of p-hydroxybenzoate Ether, stir and mix evenly, until there are no solid insolubles, join in the feed tank II102; add 634.8g epichlorohydrin in the feed tank I101; when the temperature of the constant temperature oil bath 2 rises to 90°C, Turn on the constant flow pump I601, control the flow rate to 2.2mL / min and turn on the constant flow pump II602, control the flow rate to 2.6mL / min, the liquid enters the micro-mixer 4 for mixing, after reacting in the delay reaction channel 5, light yellow The oily product I flows into the discharge tank 3.

[0046] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com