Pneumatic horizontal booster pump spraying filling machine

A pneumatic pressurization and booster pump technology, applied in spraying devices, liquid spraying devices, etc., can solve the problems of unsatisfactory spraying and pouring quality and effect, affecting the mixed use of raw materials, high heating temperature overshoot, etc., to achieve convenient and fast maintenance maintenance, saving manpower, and reducing the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

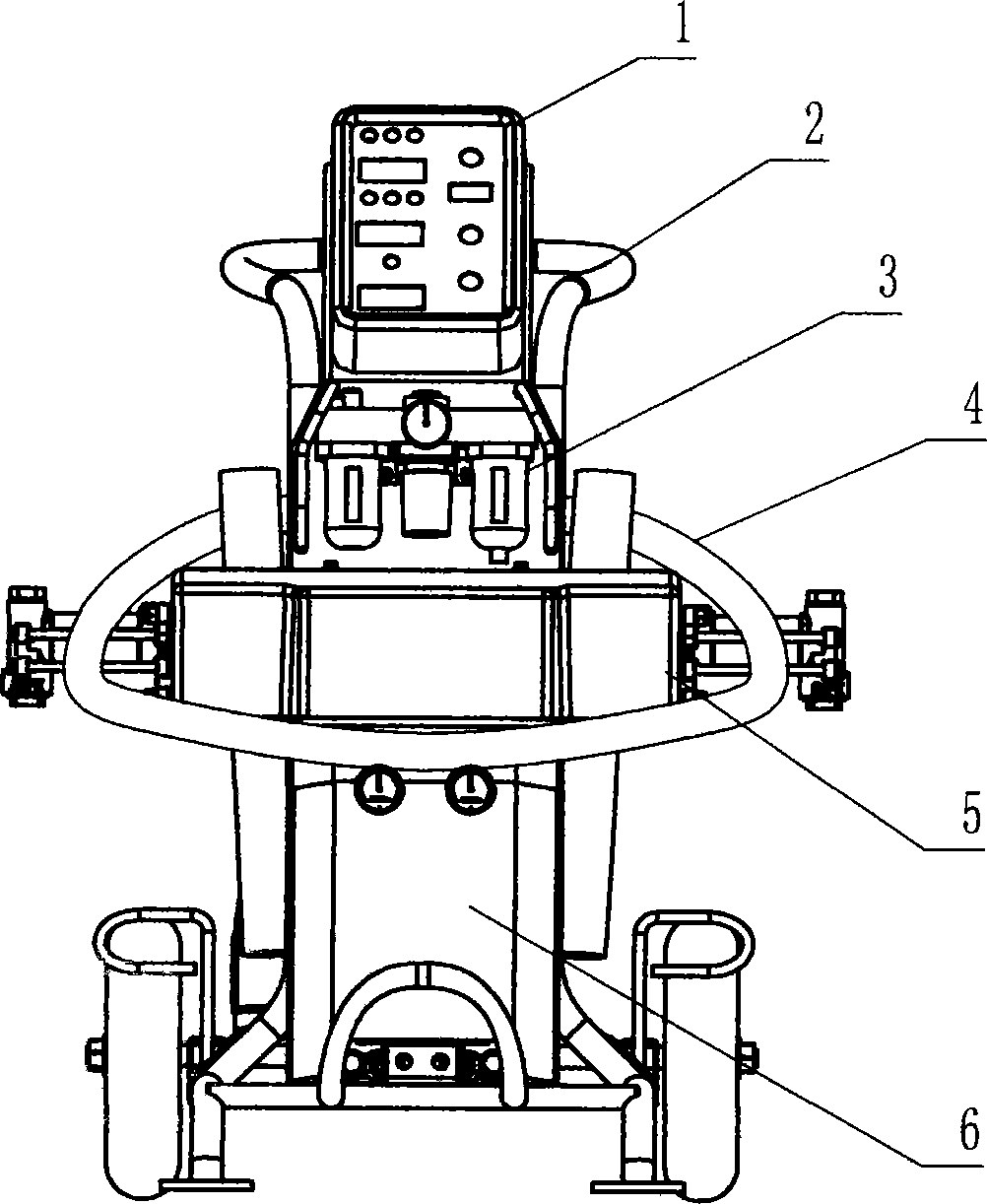

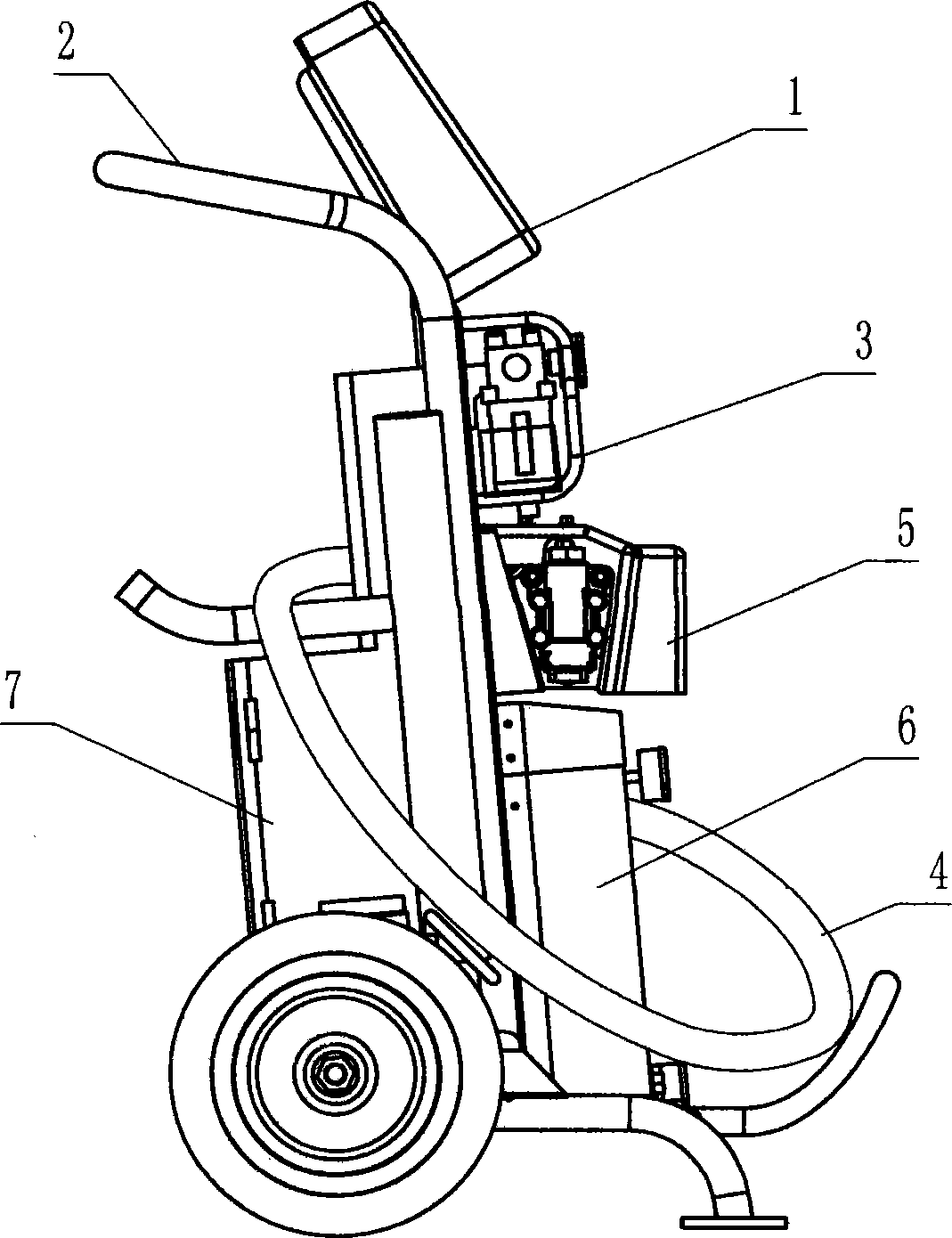

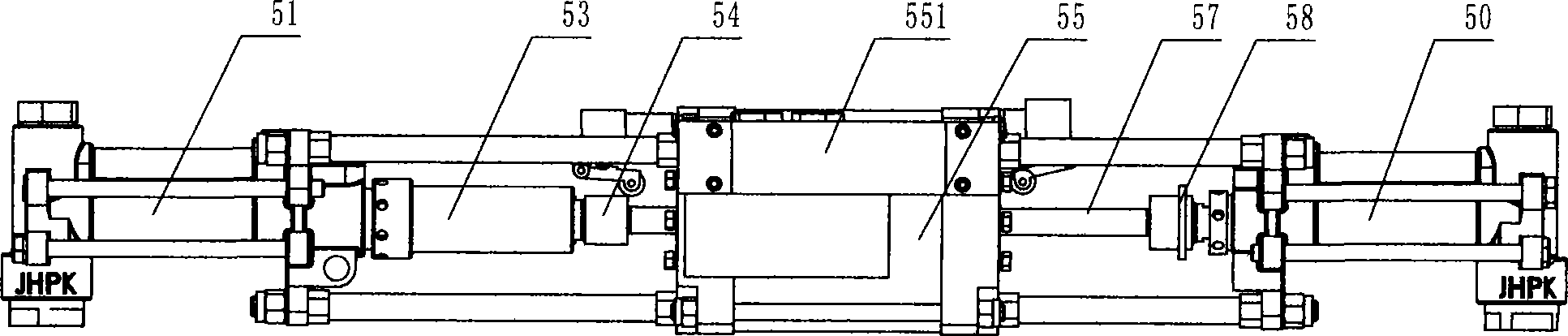

[0023] The present invention will be further described below with reference to the accompanying drawings and embodiments. Examples: refer to the accompanying drawings, a pneumatic flat-mounted booster pump spraying and filling machine, with a frame 2 with two wheels and handles, and an operating panel on the frame 1. Pneumatic triplet connected to the power source 3, heater for heating and insulating the raw materials 6, control box 7, pneumatic booster pump 5, heat preservation pipe 4, the operation panel is controlled and signaled with the control box and the pneumatic triplet The control box is connected to the heater control; the pneumatic booster pump is horizontally arranged on the frame, and a cylinder 55 is arranged in the middle of the pneumatic booster pump. The cylinder is pneumatically connected to the pneumatic triplet through the valve body control assembly 551; The piston in the middle is provided with two left and right cylinder piston rods 56, 57. The two piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com