Adjustable carbon fiber wheel rim combined structure

A combined structure, carbon fiber technology, used in wheels, spoked wheels, transportation and packaging, etc., can solve the problems of low riding energy conversion rate, unstable driving, adjustment of roundness, etc., to improve quality, reliability, and ease of use. , the effect of simple structure

Inactive Publication Date: 2012-07-18

TAISHAN SPORTS IND GRP +1

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For a bicycle, the wheel is the only part in direct contact with the ground among all its components, and it is also the part with the most frequent force changes. The quality of the wheel is of great significance to the smooth and safe driving of the bicycle; the roundness of the wheel is of great importance to The driving process has the greatest impact, and the roundness of the wheel is guaranteed by the rim. If the roundness of the rim is not good, it will cause problems such as poor fit between the tire and the rim, low conversion rate of riding energy, and unstable driving. , will affect the riding effect

For traditional bicycles, the roundness of the rim depends on the simultaneous action of dozens of steel wire spokes between the left and right sides of the wheel hub and the rim to keep it round, while for new carbon fiber bicycles, especially carbon fiber rims , due to its hardness and wear resistance compared with metal materials have a certain gap, so it is difficult to adjust the roundness with the traditional spoke adjustment method, but can only be guaranteed by the precision of the mold during the forming process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

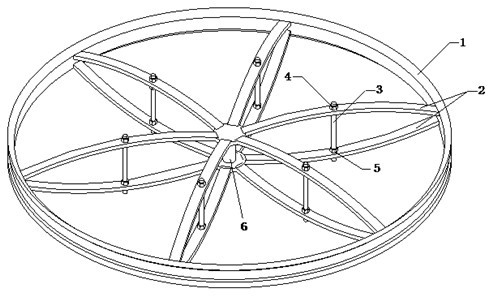

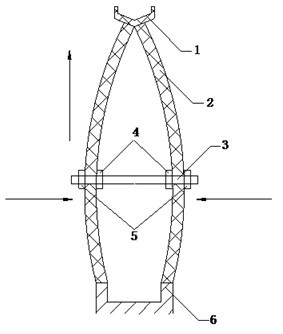

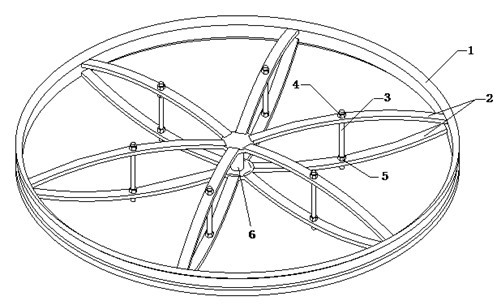

The invention belongs to the field of vehicle wheel accessories and particularly discloses an adjustable carbon fiber wheel rim combined structure which comprises a wheel frame, spokes and a hub. The adjustable carbon fiber wheel rim combined structure is characterized in that the wheel frame and the spokes are both made of a carbon fiber composite material, the two ends of the spokes are respectively connected with the two sides of the wheel frame and the hub, and the spokes are arranged symmetrically on two sides of the hub and distributed on the wheel frame evenly. The adjustable carbon fiber wheel rim combined structure is simple in structure, is convenient to use and is applicable to composite material vehicle wheels with or without an inner tube. By the adjustable carbon fiber wheel rim combined structure, the circular degree of the wheel frame can be changed through simple adjustment so that circular degree of a whole vehicle wheel can be ensured and the quality reliability of the carbon fiber composite material vehicle wheel can be improved.

Description

(1) Technical field The invention belongs to the field of wheel accessories, in particular to an adjustable carbon fiber rim composite structure. (2) Background technology The bicycle is mainly a means of transportation powered by human pedaling. It combines the principles of ergonomics and aerodynamics, and has many parts, including frame, fork, handle, rim, chain and so on. In order to reduce the weight of bicycles and save the physical strength of riders, bicycles have been gradually developed from metal materials to carbon fiber composite materials. Compared with metal materials, carbon fiber composite materials have a density of only 1.6g / m 3 , which is only 1 / 5 of steel, so it can greatly reduce the weight of bicycles; in addition, carbon fiber composite materials also have the advantages of excellent corrosion resistance, high specific strength, and high specific modulus; firstly, composite parts made of carbon fiber composite materials include front and rear fork...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B60B1/02B60B1/04

Inventor 龙国荣杨小兵卞志勇王春青

Owner TAISHAN SPORTS IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com