Multilayer fuel gas storage well cylinder used for high-pressure underground fuel gas storage well and molding-fixing method thereof

A fixing method, a technology for gas storage wells, applied in the directions of transportation and packaging, storage devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

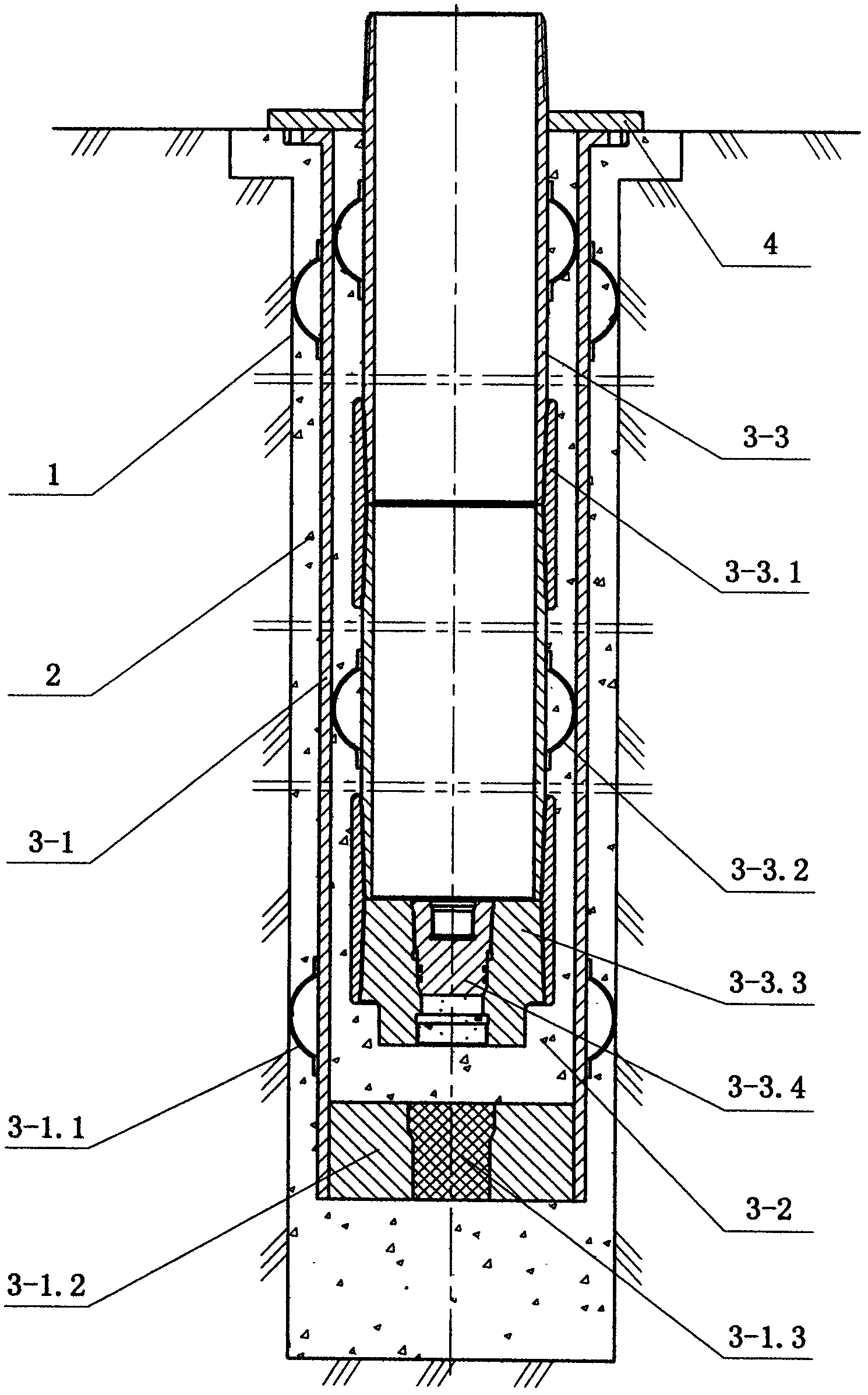

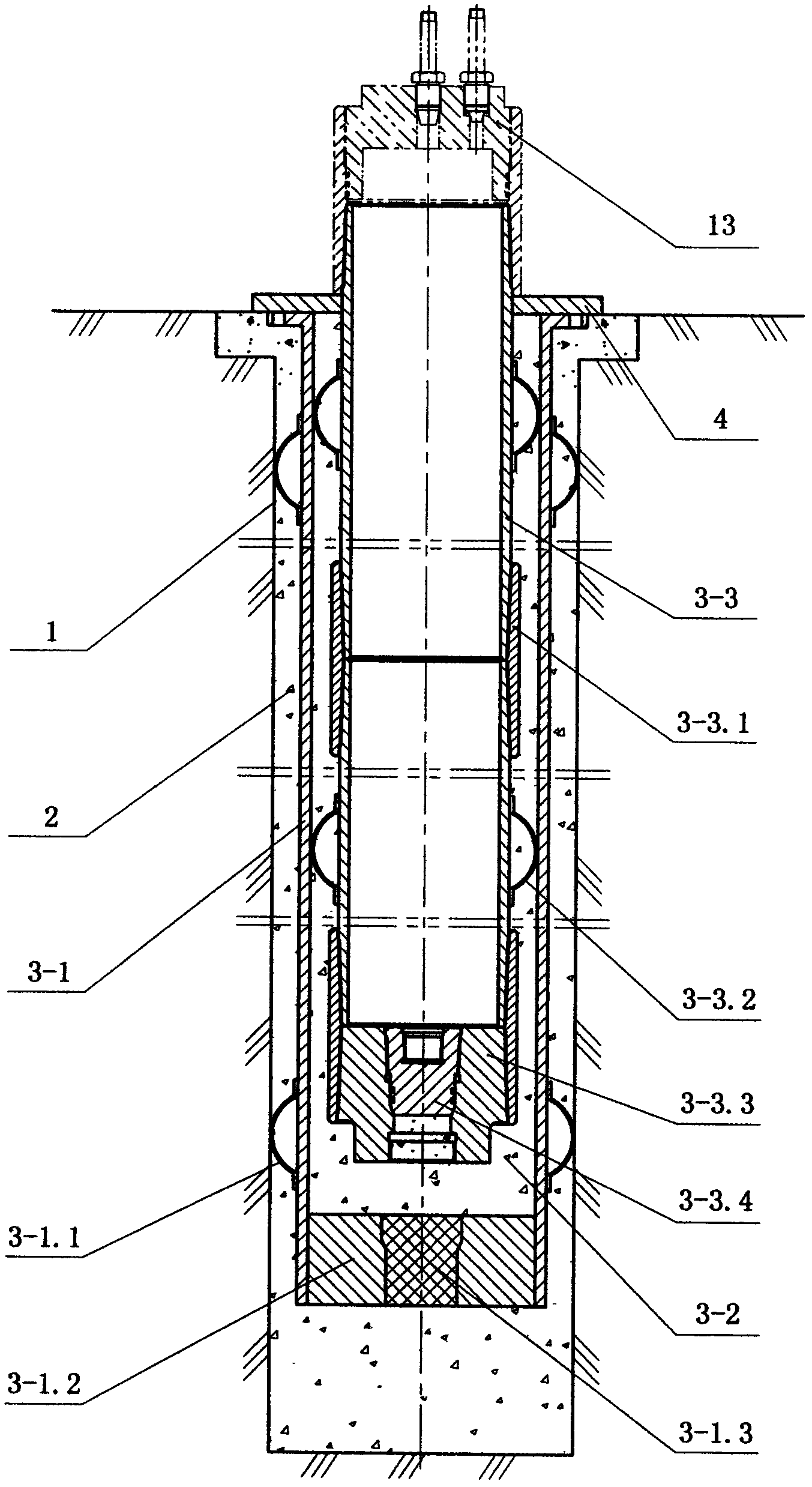

[0020] Embodiment 1: In this embodiment, the multi-layer gas storage well cylinder body for natural gas underground gas storage wells used in CNG filling stations, urban gas peak-shaving stations, and storage and distribution stations is taken as an example: the specification of the outer cylinder body 3-1 is Φ323.9×6mm , the gas storage cylinder 3-3 adopts a diameter of Φ244.48mm (9 5 / 8 ″) casing, the effective gas storage part is 100m deep, and the gas storage pressure is 25Mpa. The forming and fixing method of the multi-layer gas storage well casing is as follows:

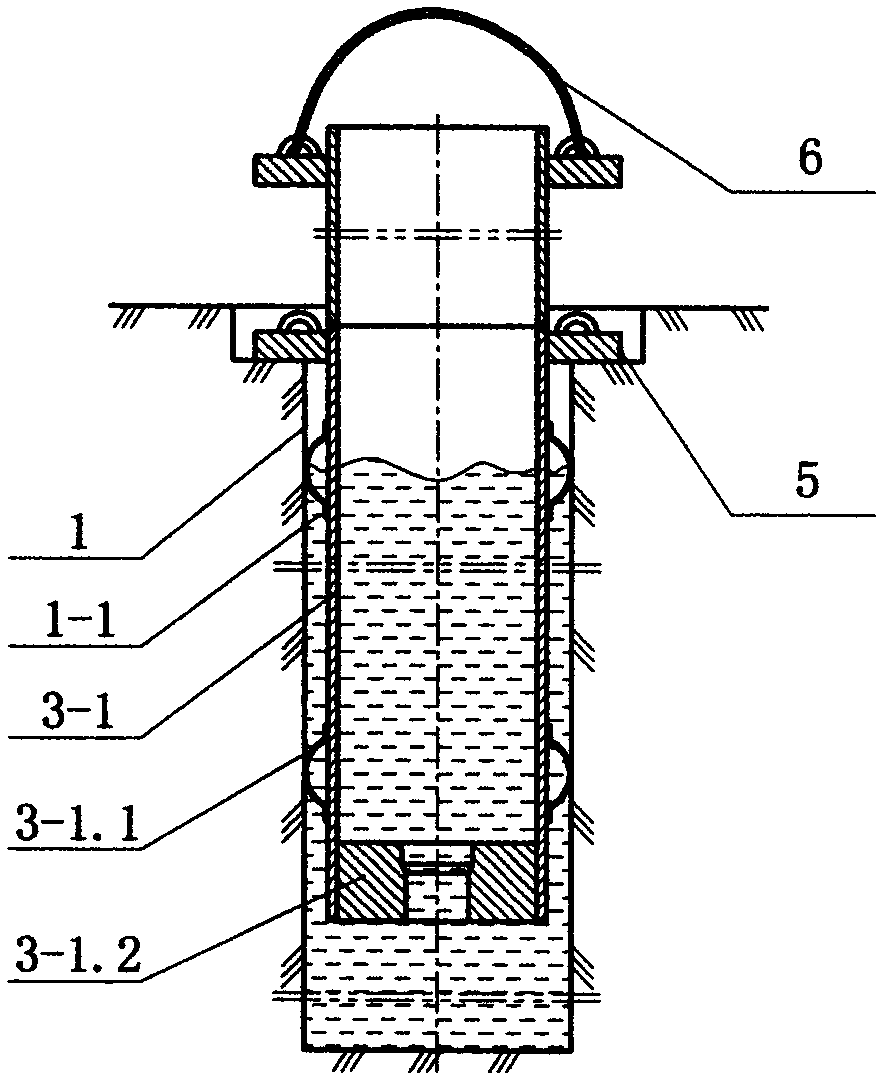

[0021] Step A. Lower the outer cylinder 3-1: first drill a foundation well 1 with a diameter of Φ400mm and a depth of not less than 105m according to oil and natural gas drilling technology and procedures, and then lift the splint through the outer cylinder according to the fixing method of the conventional underground gas storage well shaft 5 and lifting lug 6 to lower the outer cylinder body 3-1 with the gr...

Embodiment 2

[0026] Embodiment 2: This embodiment takes the grouting process hole plug 3-3.4 at the bottom of the gas storage cylinder 3-3 as an example. The cement slurry pouring in the annular space between -1 adopts the method disclosed by one of the applicants of the present invention in the patent document whose notification number is CN1837672B; Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com