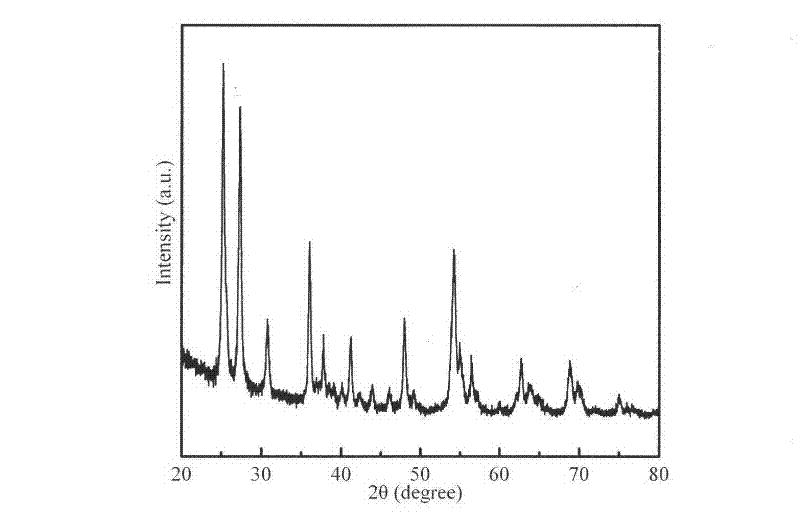

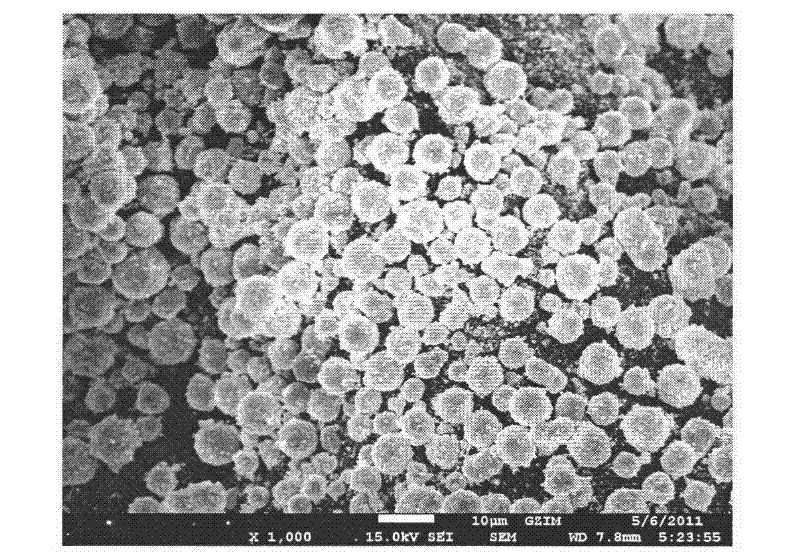

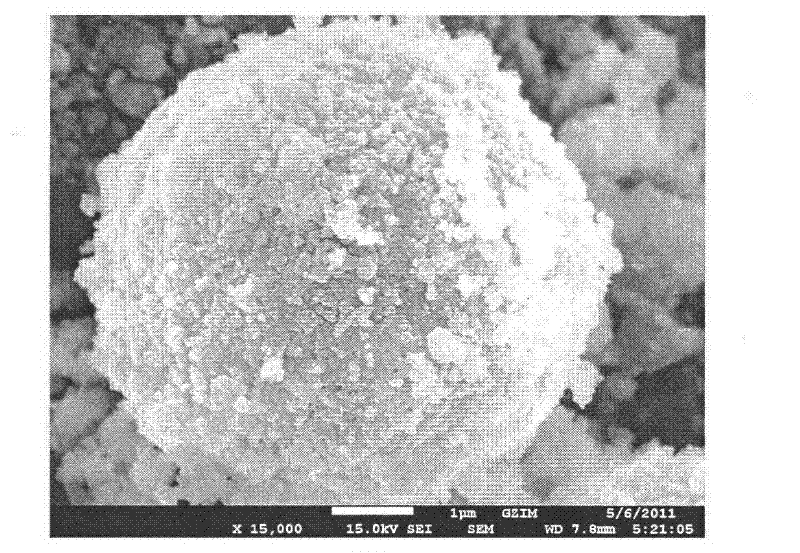

Preparation method of titanium dioxide classification balls containing three crystalline phases

A technology of titanium dioxide and dodecyl trimethyl ammonium bromide, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., to achieve the effects of simple process control process, easy large-scale synthesis and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) 0.25 gram of analytically pure dodecyltrimethylammonium bromide is added into a mixed solvent of 30 milliliters of dehydrated alcohol and 30 milliliters of deionized water and stirred evenly, and then 0.4 milliliters of analytically pure tartaric acid is added, Stir and mix evenly at room temperature to obtain a mixed solution;

[0017] (2) Add 1 ml of analytically pure butyl titanate dropwise to the mixed solution in step (1), and continue stirring until no white flocs appear;

[0018] (3) the solution that step (2) is made is transferred in the high-temperature reactor of 100 milliliters;

[0019] (4) Put the high-temperature reaction kettle of step (3) into a constant temperature drying oven and keep it warm at 120° C. for 24 hours, and naturally cool to room temperature to obtain a white precipitate;

[0020] (5) The white precipitate obtained in step (4) was reversed twice with deionized water or absolute ethanol, and then dried in a drying oven at 60° C. for ...

Embodiment 2

[0023] (1) 0.3 gram of analytically pure dodecyltrimethylammonium bromide is added into a mixed solvent of 30 milliliters of dehydrated alcohol and 30 milliliters of deionized water and stirred evenly, then 0.8 milliliters of analytically pure tartaric acid is added, Stir and mix evenly at room temperature to obtain a mixed solution;

[0024] (2) Add 2 milliliters of analytically pure butyl titanate dropwise to the mixed solution in step (1), and continue stirring until no white flocs appear;

[0025] (3) the solution that step (2) is made is transferred in the high-temperature reactor of 100 milliliters;

[0026] (4) Put the high-temperature reaction kettle of step (3) into a constant temperature drying oven and keep it warm at 150° C. for 48 hours, and naturally cool to room temperature to obtain a white precipitate;

[0027] (5) Wash the white precipitate obtained in step (4) with deionized water or absolute ethanol repeatedly for 3 times, and then dry it in a drying oven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com