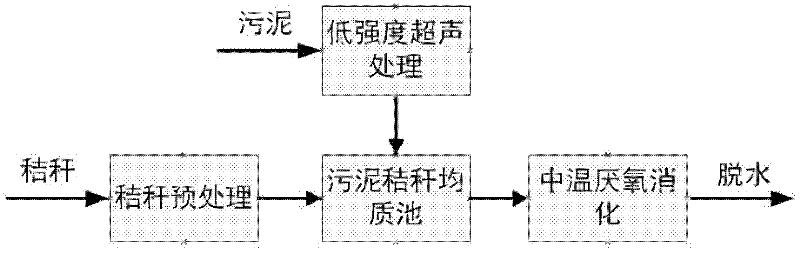

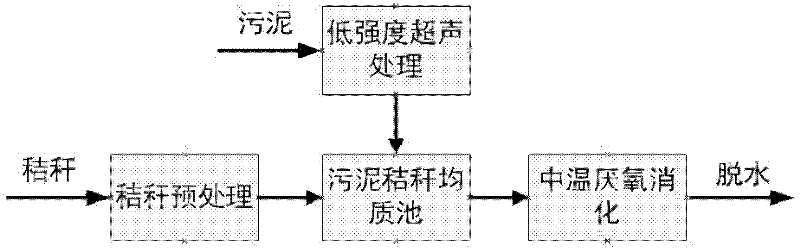

Method for performing mixed fermentation on low-intensity ultrasonically disintegrated sludge and crop straws and application of method in improving mesophilic anaerobic digestion

A crop straw and mixed fermentation technology, applied in sludge treatment, biological sludge treatment, chemical instruments and methods, etc., can solve the problems of large volume of sludge digestion structures, long hydraulic retention time, increased construction and operation costs, etc. Achieve significant social and economic benefits, improve disposal levels, and reduce sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh the corn stalk powder, pass through a 50-mesh sieve, fully mix the corn stalk powder and tap water according to the solid-to-liquid ratio of 1:10 (mass ratio), to ensure that the straw is soaked in the tap water. Treat in the straw pretreatment pool for 12h. TCOD in the liquid phase increased by 2000mg / L after pretreatment

[0019] The sludge is transported by the sludge pump to the multi-probe ultrasonic processor (6) for cracking. The frequency of the ultrasonic reactor is 20kHz, the diameter of the probe is 20mm, and the sound energy density is 0.2kW / m 3 , the solid content of the sludge is 2.3%, and the cracking time is 3 minutes. After cracking, the TCOD in the sludge liquid phase increased by 1000mg / L.

[0020] After pretreatment, the wet corn stalks and sludge enter the mixing tank to be fully mixed (the mixing mass ratio is 1:1.4), and the mixture enters the mesophilic anaerobic digestion tank for reaction, and the hydraulic retention time is 200h. The ...

Embodiment 2

[0022] Weigh the wheat straw powder, pass through a 20-mesh sieve, fully mix the wheat straw powder and tap water according to the solid-to-liquid ratio of 1:12 (mass ratio), to ensure that the straw is soaked in the tap water. Treat in the straw pretreatment pool for 20h. After pretreatment, TCOD in the liquid phase increased by 2511mg / L

[0023] The sludge is transported by the sludge pump to the multi-probe ultrasonic processor (6) for cracking. The frequency of the ultrasonic reactor is 28kHz, the diameter of the probe is 25mm, and the sound energy density is 0.5kW / m 3 , the solid content of the sludge is 2.1%, and the cracking time is 8 minutes. After cracking, TCOD in the sludge liquid phase increased by 1742mg / L.

[0024] After pretreatment, the wet wheat straw and sludge enter the mixing tank to be fully mixed (the mixing mass ratio is 1:1.6), and the mixture enters the mesophilic anaerobic digestion tank for reaction, and the hydraulic retention time is 216h. The c...

Embodiment 3

[0026] The sorghum straw powder was weighed, passed through a 20-mesh sieve, and the sorghum straw powder was fully mixed with tap water at a solid-to-liquid ratio of 1:15 (mass ratio) to ensure that the straw was soaked in the tap water. Treat in the straw pretreatment pool for 40h. After pretreatment, TCOD in the liquid phase increased by 3217mg / L

[0027] The sludge is transported by the sludge pump to the multi-probe ultrasonic processor (6) for cracking. The frequency of the ultrasonic reactor is 28kHz, the diameter of the probe is 25mm, and the sound energy density is 0.8kW / m 3 , the solid content of the sludge is 2.4%, and the cracking time is 10 minutes. After cracking, TCOD in the sludge liquid phase increased by 2327mg / L.

[0028] After pretreatment, wet sorghum stalks and sludge enter the mixing tank to be fully mixed (the mixing mass ratio is 1:1.8), and the mixture enters the mesophilic anaerobic digester for reaction, and the hydraulic retention time is 288h. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com