Efficient laminated sludge dehydrator

A sludge dewatering machine and lamination technology, which is applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of low treatment efficiency, increase water intake, balance and efficient workload, and improve work efficiency and energy. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

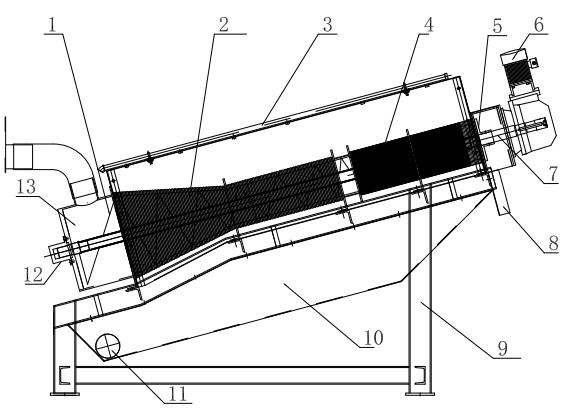

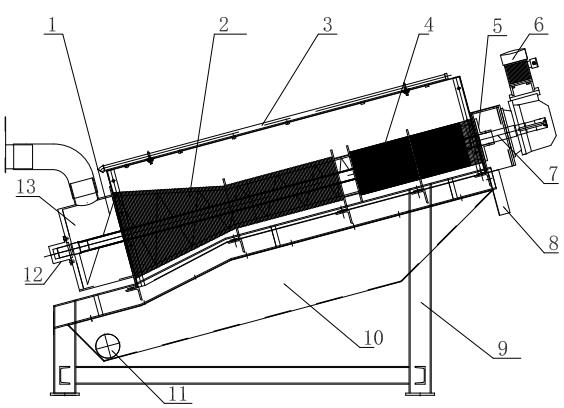

[0012] Such as figure 1 As shown, the basic structure of the high-efficiency laminated sludge dewatering machine described in the present invention is the same as that of the existing laminated sludge dewatering machine. It consists of two sections, the front stage concentration part 2 and the rear stage dehydration part 4. The filter cartridge is installed on the bracket 9 at a certain angle in an oblique upward manner. The water inlet chamber 13 is located at the front end of the concentration part 2. The screw shaft 7 is set on the In the center of the filter cartridge, the auger motor 6 installed at the rear end of the dehydration part 4 is driven to rotate, and the spiral blade 1 continuously pushes the sludge forward, and at the same time, it also continuously drives the swimming ring to clean the filter joints to prevent clogging. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com