Polycarboxylic acid slump retaining agent for concrete and preparation method thereof

A technology of polycarboxylic acid and slump-retaining agent, which is applied in the field of concrete slump-retaining agent, can solve the problems of poor concrete workability, influence on concrete construction, and unstable plastic-retaining performance, and achieve stable plasticity, facilitate industrial production, The effect of stabilizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

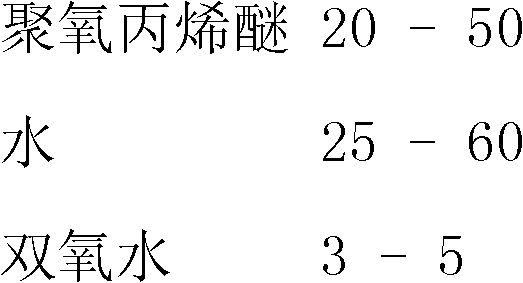

[0035] A polycarboxylate slump-retaining agent for concrete, the weight percentage of each component is:

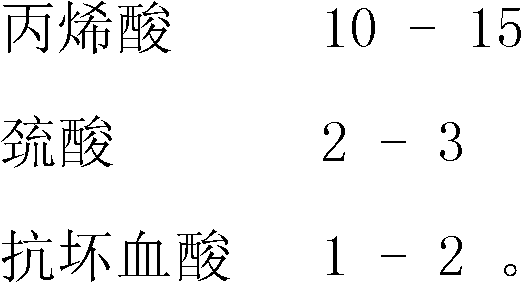

[0036]

[0037]

Embodiment 2

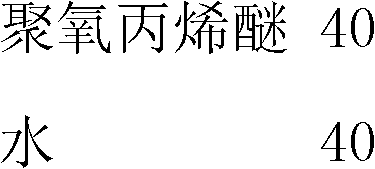

[0039] A kind of preparation method of polycarboxylate slump-retaining agent for concrete, its preparation comprises following technological steps:

[0040] 1. Add 40g of polyoxypropylene ether and 10g of water into the reaction vessel, and raise the temperature to 60°C to dissolve the polyoxypropylene ether in water. Adjust the pH between 4-6 with acrylic acid.

[0041] 2. Add 3g of hydrogen peroxide into the reaction kettle and stir for 10-20 minutes to fully dissolve the hydrogen peroxide.

[0042] 3. Dissolve the remaining acrylic acid (10 g in total), 2 g of mercapto acid, and 1 g of ascorbic acid in a small amount of water, and drop them into the reaction vessel within 3-5 hours.

[0043] 4. After the dropwise addition, keep warm for 1-2 hours.

[0044] 5. Regulate the ph value (6-7) with sodium hydroxide, add water and dilute to 40%, both obtain polycarboxylate slump retaining agent for concrete.

Embodiment 3

[0046] A kind of preparation method of polycarboxylate slump-retaining agent for concrete, its preparation comprises following technological steps:

[0047] 1. Add 50g of polyoxypropylene ether and 20g of water into the reaction vessel, and raise the temperature to 80°C to dissolve the polyoxypropylene ether in water. Adjust the pH between 4-6 with acrylic acid.

[0048] 2. Add 5g of hydrogen peroxide into the reaction vessel and stir for 10-20 minutes to fully dissolve the hydrogen peroxide.

[0049] 3. Dissolve the remaining acrylic acid (15 g in total), 3 g of mercapto acid, and 2 g of ascorbic acid in a small amount of water, and add them dropwise to the reaction vessel within 3-5 hours.

[0050] 4. After the dropwise addition, keep warm for 1-2 hours.

[0051] 5. Regulate the ph value (6-7) with sodium hydroxide, add water and dilute to 40%, both obtain polycarboxylate slump retaining agent for concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com