Waterborne epoxy ester-modified polycarboxylate superplasticizer as well as preparation method and application thereof

A technology of epoxy ester and polycarboxylic acid, which is applied in the field of building materials, can solve the problems of unfavorable large-scale promotion and high price, and achieve the effects of good strength, simple production equipment, and good shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

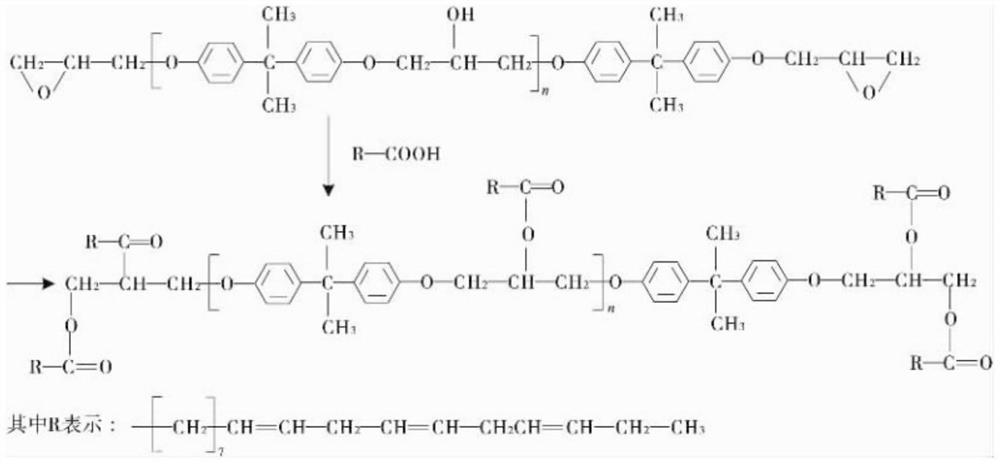

Method used

Image

Examples

Embodiment 1

[0053] Preparation of waterborne epoxy esters:

[0054] Add linolenic acid into a four-necked flask equipped with mechanical stirring, water separator (including condenser), thermometer and nitrogen inlet device, start stirring and pass in nitrogen protection, heat up to 150°C within 1h, and then add epoxy Resin E-12, the weight ratio of linolenic acid to epoxy resin E-12 is 0.6:1. After the epoxy resin E-12 is melted, add the catalyst monobutyltin oxide, then raise the temperature to 200°C within 1.5 hours, keep warm for esterification, and take samples every 0.5 hours to measure the acid value and viscosity. When the acid value drops below 3mgKOH / g, stop heating, immediately cool down, and when the temperature drops to 60°C, add n-butanol and ethylene glycol butyl ether (system solid content is 60%) to obtain water-based epoxy ester.

[0055] Preparation of water-based epoxy ester modified polycarboxylate water reducer:

[0056] Step A, in the 1L four-neck flask with a cap...

Embodiment 2

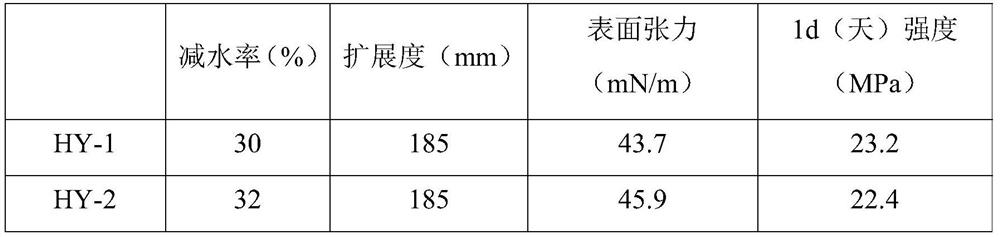

[0062] According to the preparation method of Example 1, the difference is: when preparing the bottom liquid in step A, add 100g of water-based epoxy ester to obtain the polycarboxylate water-reducer HY-2 modified by water-based epoxy ester, and carry out The performance test results are shown in Table 1.

Embodiment 3

[0064] According to the preparation method of Example 1, the difference is: when preparing the bottom liquid in step A, add 300g water-based epoxy ester to obtain the polycarboxylate water-reducer HY-3 modified by water-based epoxy ester, and carry out The performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com