A kind of scutellarin aglycone liposome preparation and preparation method thereof

A technology of scutellarin aglycone lipid and scutellarin aglycone, which is applied in the field of liposome containing insoluble Chinese herbal medicine active ingredient scutellarin aglycon and its preparation field, can solve the influence of scutellarin aglycon on stability , Poor chemical stability, short half-life, etc., to achieve good shape and encapsulation rate, maintain blood drug concentration, and increase drug concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0083] Preparation method of scutellarin aglycone liposome preparation

[0084] The preparation method of the scutellarin aglycone liposome preparation of the present invention comprises:

[0085] (1) prepare inner aqueous phase and outer aqueous phase and all contain the blank liposome of acetate aqueous solution;

[0086] (2) preparing blank liposomes whose inner water phase contains acetate aqueous solution and whose outer water phase contains physiological isotonic solution;

[0087] (3) Mix the blank liposome obtained in step (2) with the scutellarin aglycone solution, incubate, remove free scutellarin aglycone, and obtain a scutellarin aglycone liposome preparation.

[0088] The acetate may be sodium acetate or calcium acetate.

[0089] The concentration of acetate in the acetate aqueous solution may be 50mM˜500mM. It can also be 150mM-500mM.

[0090] The pH range of the acetate aqueous solution may be 5.0-9.0. The pH value range of the acetate aqueous solution may ...

Embodiment 1

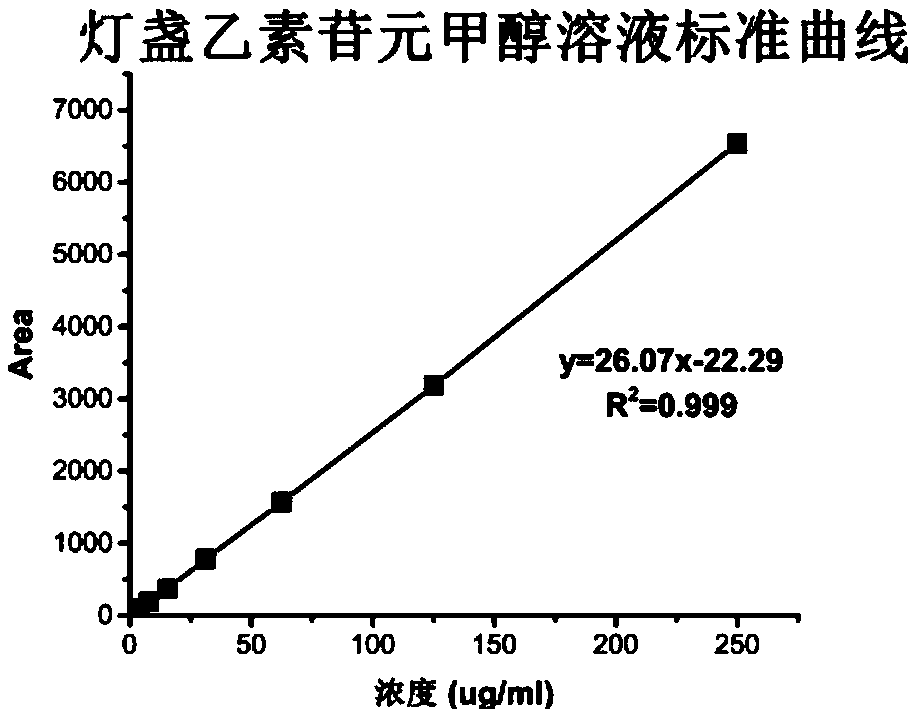

[0114] Example 1 The solubilization of different cosolvents to scutellarin aglycon

[0115] 1. Sodium bicarbonate, PEG300, PEG400, and propylene glycol were purchased from Sinopharm Chemical Reagent Co., Ltd., and hydroxypropyl-β-cyclodextrin (HPCD) was purchased from Shifeng Biological Co., Ltd.

[0116] 2. The influence of different co-solvents on the solubility of scutellarin aglycone:

[0117] (1) Precisely weigh 4.9983g of sodium bicarbonate and dissolve it in 100ml of 18.2MΩ water to obtain a 5% sodium bicarbonate aqueous solution; precisely weigh 1.2034mg of scutellarin aglycon and dissolve it in 1ml of 5% sodium bicarbonate solution.

[0118](2) Accurately weigh 9.8174mg, 9.9035mg, and 9.8665mg scutellarin aglycone respectively, dissolve them in 1 mg PEG300, PEG400, and propylene glycol solution respectively, vortex for 3 minutes, and ultrasonicate for 30 minutes, and the scutellarin aglycone is fully dissolved to obtain scutellarin Vegetarian aglycone suspension, the...

Embodiment 2

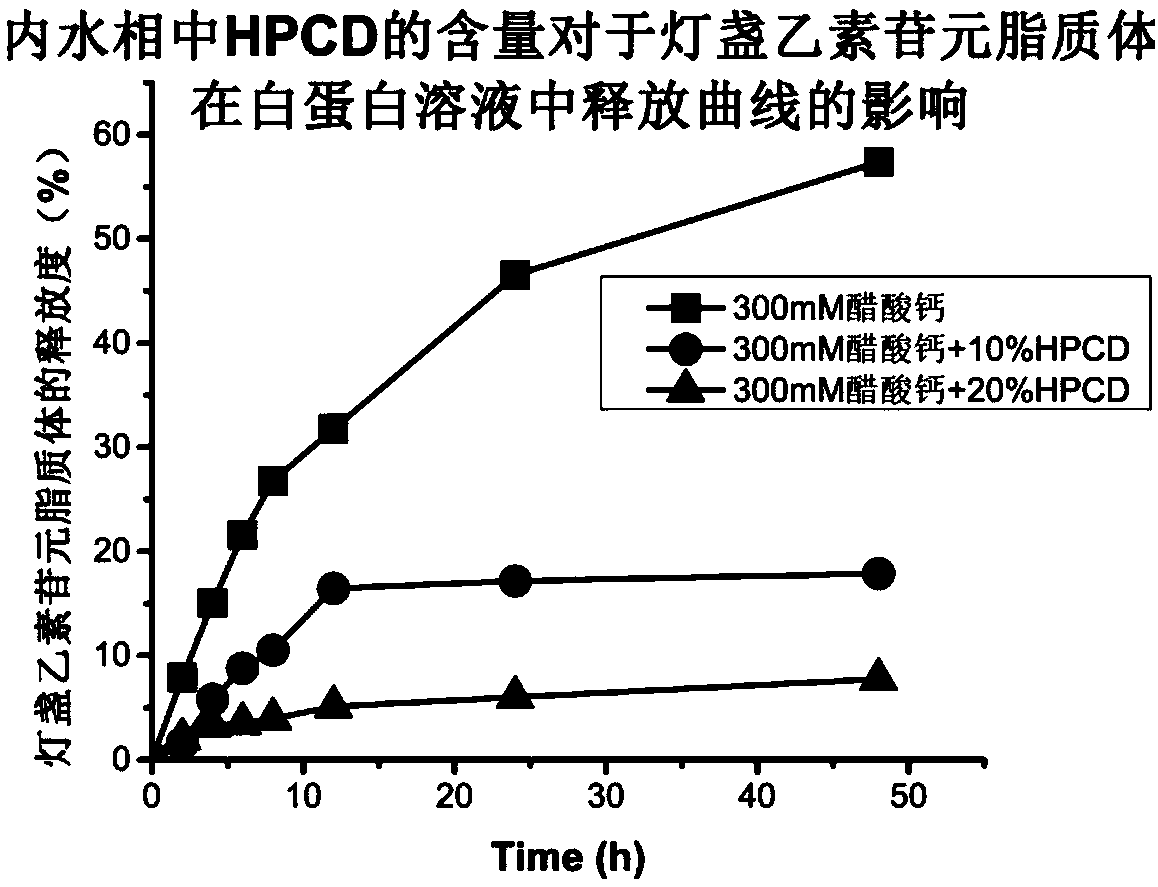

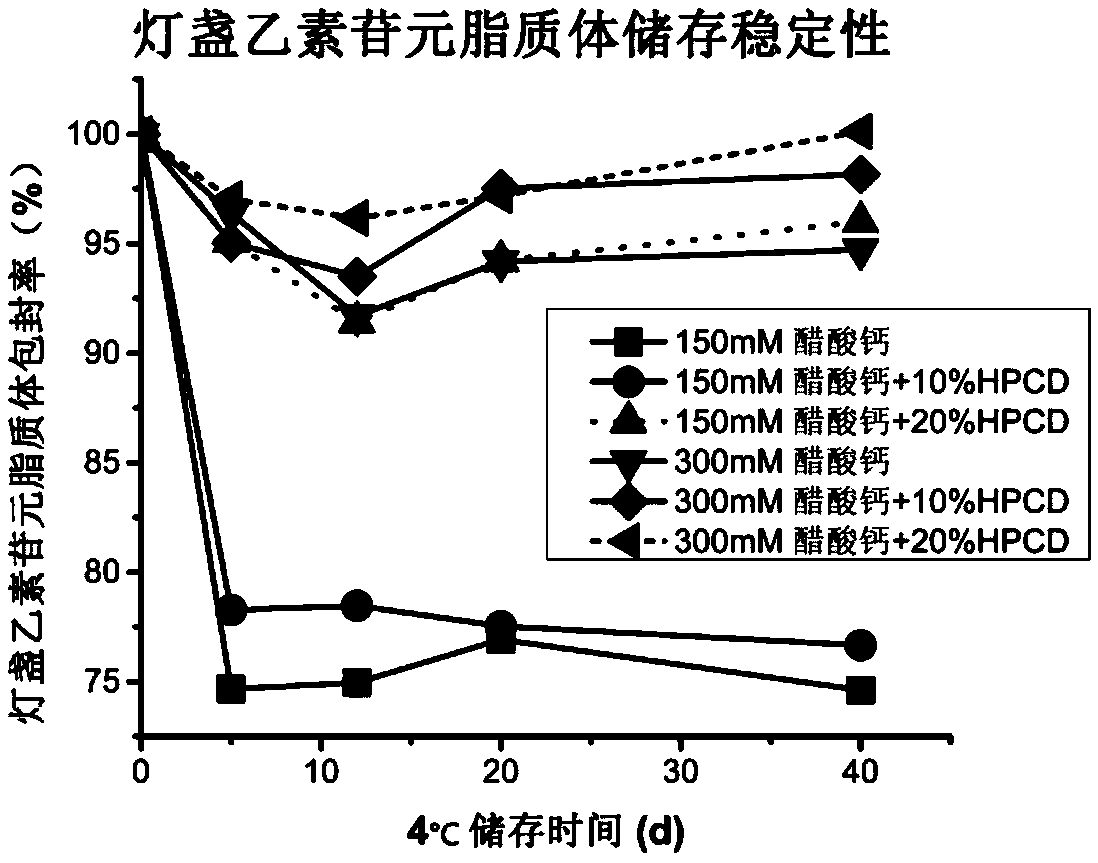

[0134] Example 2 Preparation and characterization of scutellarin aglycone liposomes

[0135] 1. Hydrogenated soy lecithin (HSPC) was purchased from NOF Corporation, and pegylated phospholipids: distearoylphosphatidylethanolamine-polyethylene glycol 2000 (DSPE-PEG2000) and cholesterol were purchased from Avanti PolarLipids, USA ; Scutellarin aglycone was purchased from Nanjing Jingzhu Biotechnology Co., Ltd.; calcium acetate was purchased from Sinopharm Chemical Reagent Co., Ltd.

[0136] 2. Preparation of scutellarin aglycon liposomes

[0137] (1) Accurately weigh 479.9 mg of cholesterol (CHOL, molecular weight 386.7), 160.9 mg of hydrogenated soybean lecithin (HSPC, molecular weight 783.8) and 160.8 mg of distearoylphosphatidylethanolamine-polyethylene glycol 2000 (DSPE-PEG2000), add 1 milliliter of ethanol was bathed in a water bath at 70 degrees Celsius to fully dissolve and mix to obtain a lipid-ethanol mixed solution;

[0138] (2) Add 10 milliliters of pH 7.40300mM calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com