Organic and inorganic slow-release compound fertilizer and preparation method thereof

A slow-release compound fertilizer and inorganic technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as overuse, achieve convenient application, reduce leaching and volatilization losses, and improve the soil environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

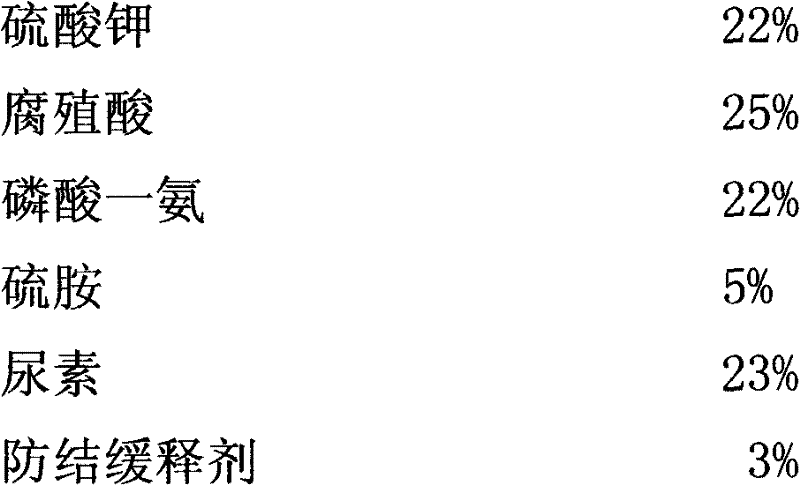

[0029] An organic-inorganic slow-release compound fertilizer is made of the following raw materials in weight percentage:

[0030]

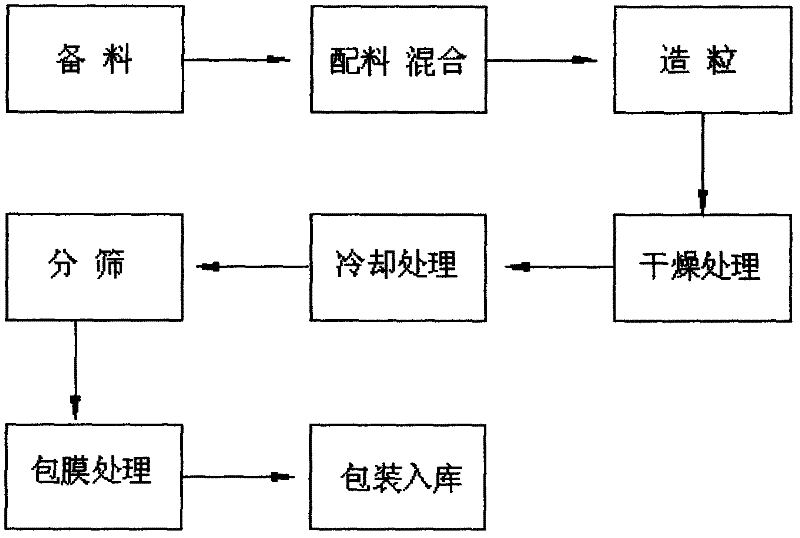

[0031] Its preparation method steps are as follows:

[0032] First weigh 240kg of potassium sulfate, 270kg of humic acid, 240kg of monoammonium phosphate, 55kg of thiamine, 250kg of urea, and 35kg of slow-release agent; then sprinkle 270kg of humic acid evenly on other raw materials and put them in the crusher for Crushing and mixing, the crushing effect is 105 mesh; then put the uniformly mixed raw materials into the granulator for granulation, the granulation steam pressure is 0.7mp, the granulation temperature is 39°C, and the granulation rate after granulation is 85 %; then put the pellets into the dryer for drying, the drying temperature is: the inlet temperature is 135°C, and the outlet temperature is 60°C; then put the dried pellets into the cooler to cool, and the The final granules are sub-sieved twice to improve the uniformity; then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com