Ultrahigh temperature tungsten rod heater

A heater and ultra-high temperature technology, applied in chemical instruments and methods, single crystal growth, polycrystalline material growth, etc., can solve the problems of increased water vapor pressure, increased process difficulty, increased cost, etc. The effect of reducing process difficulty and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment technical scheme of the present invention is described in detail as follows:

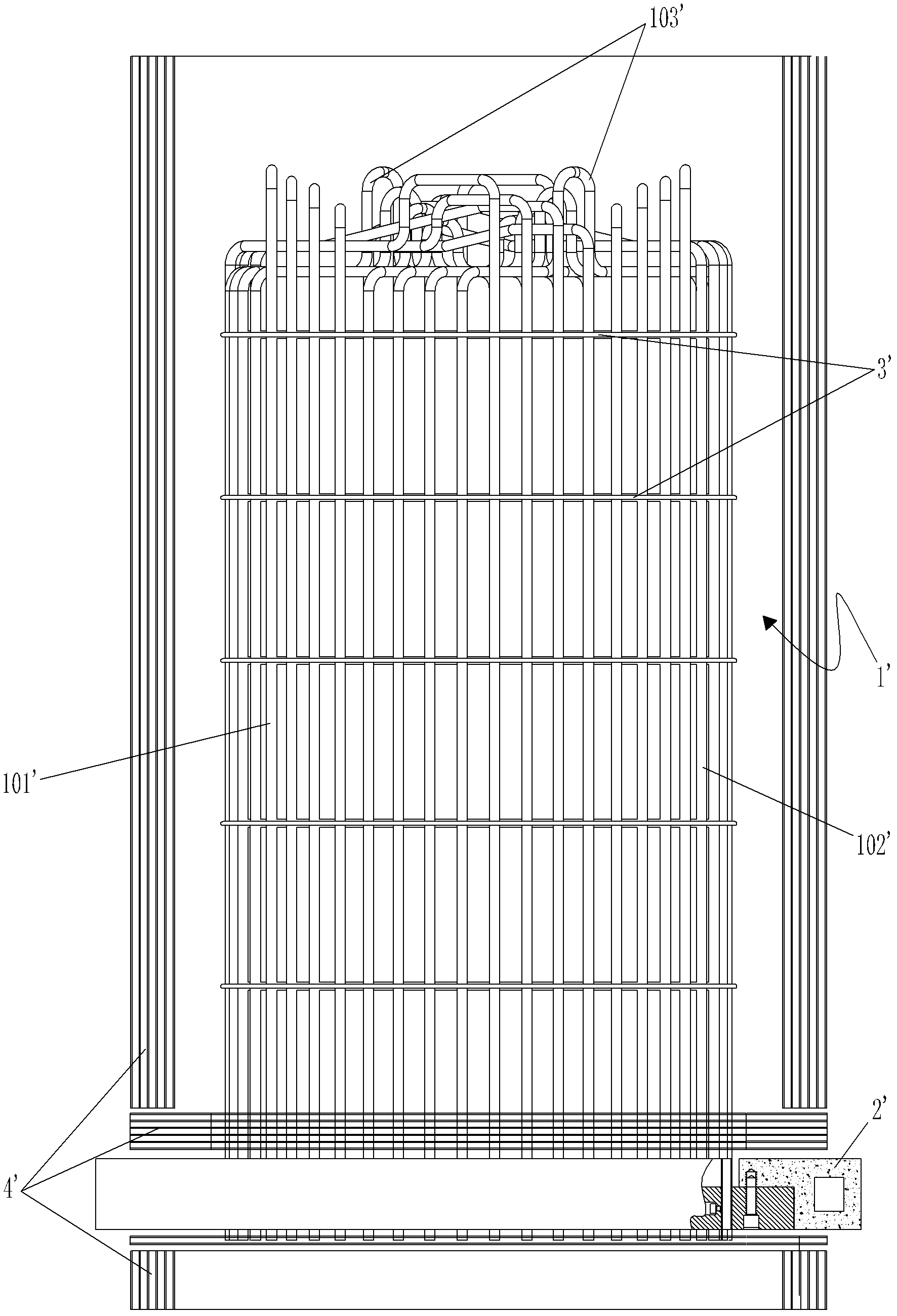

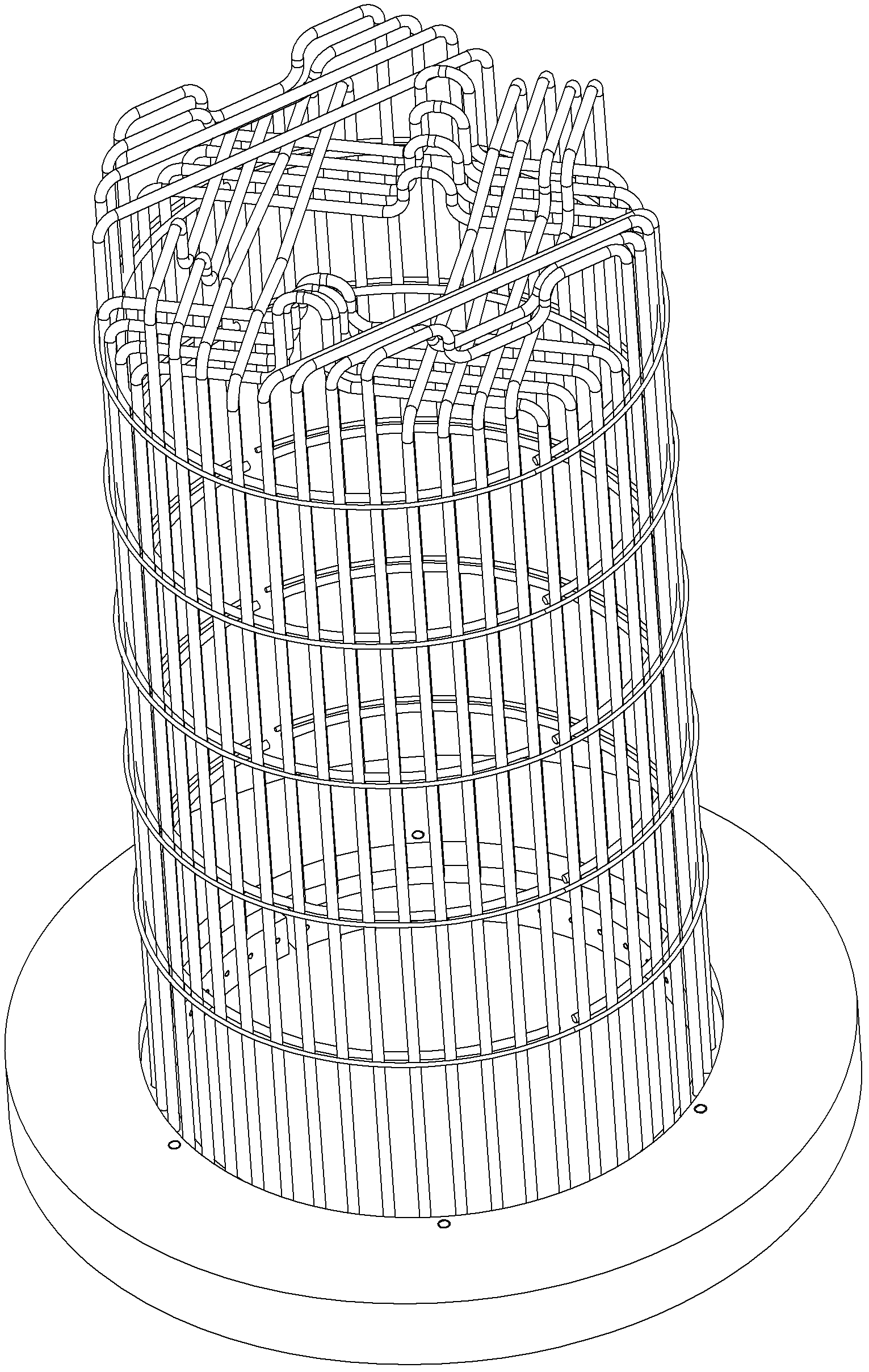

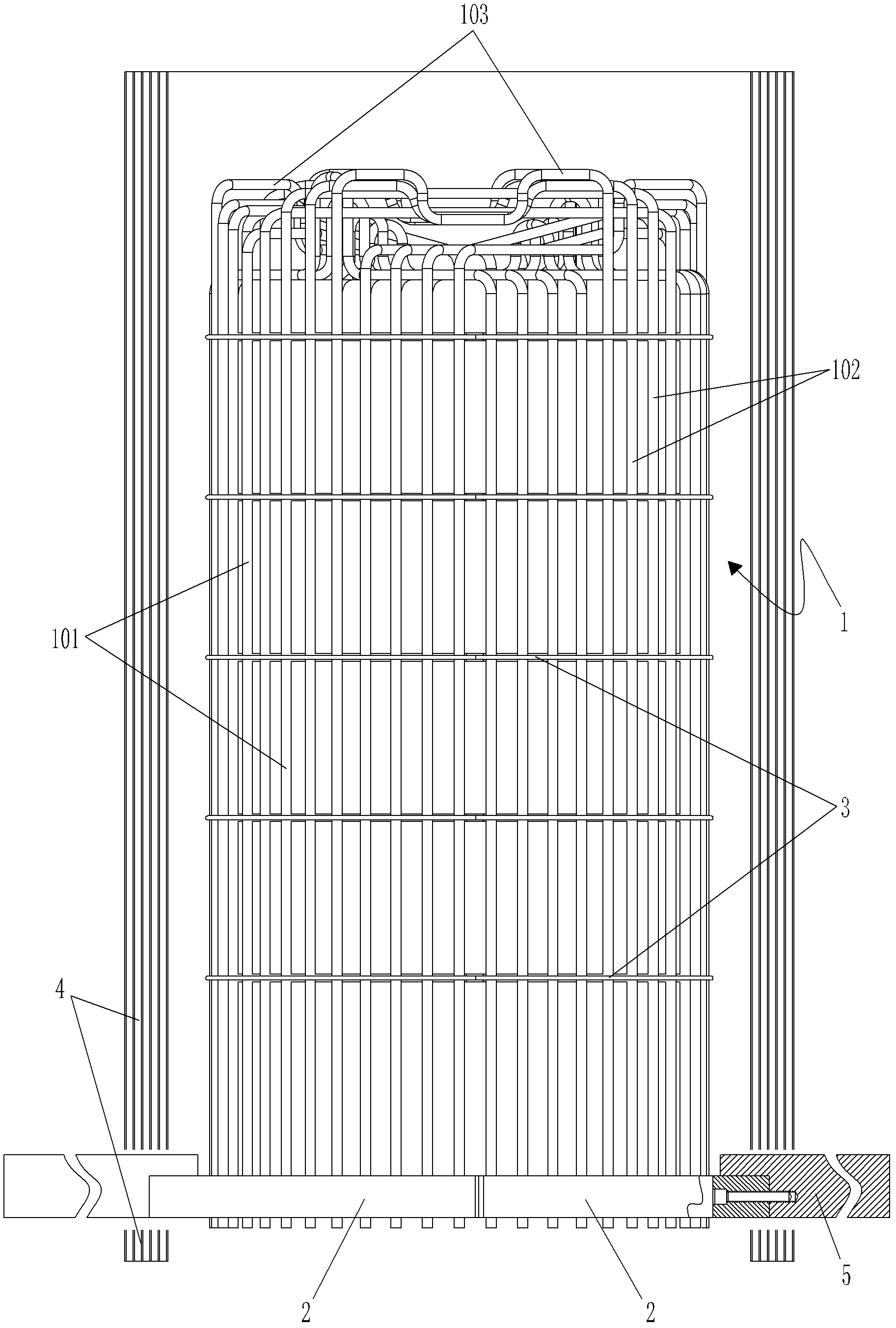

[0020] as attached image 3 , attached Figure 4 and attached Figure 5 As shown, the tungsten rod 1 heater for ultra-high temperature of the present invention includes a tungsten flange made of metal tungsten and a plurality of tungsten rods 1, and the tungsten flange is composed of a plurality of arc-shaped units 2, and these arc-shaped units are divided into two parts. It is the first group and the second group with equal numbers distributed along two semicircles, and each tungsten rod 1 includes a first straight section 101, a second straight section 102 and a The transition section 103 between them is U-shaped, and each first straight section 101 is vertically fixed on the arc-shaped unit 2 in the first group, and the second straight section 102 is vertically fixed on the arc-shaped unit 2 in the second group. , the whole heater is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com