Spatial combined arched shell structure with two layers of cylindrical surfaces

A space combination and cylindrical surface technology, applied to arch structures, dome structures, building components, etc., can solve the problem of reducing the survival and continuous combat capabilities of ground maneuvering targets, and exceeding the requirements of penetration resistance and earthquake resistance. Structure layer thickness, constraints The protection efficiency of single shielding facilities and other issues can be achieved by simple construction, large space rigidity and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

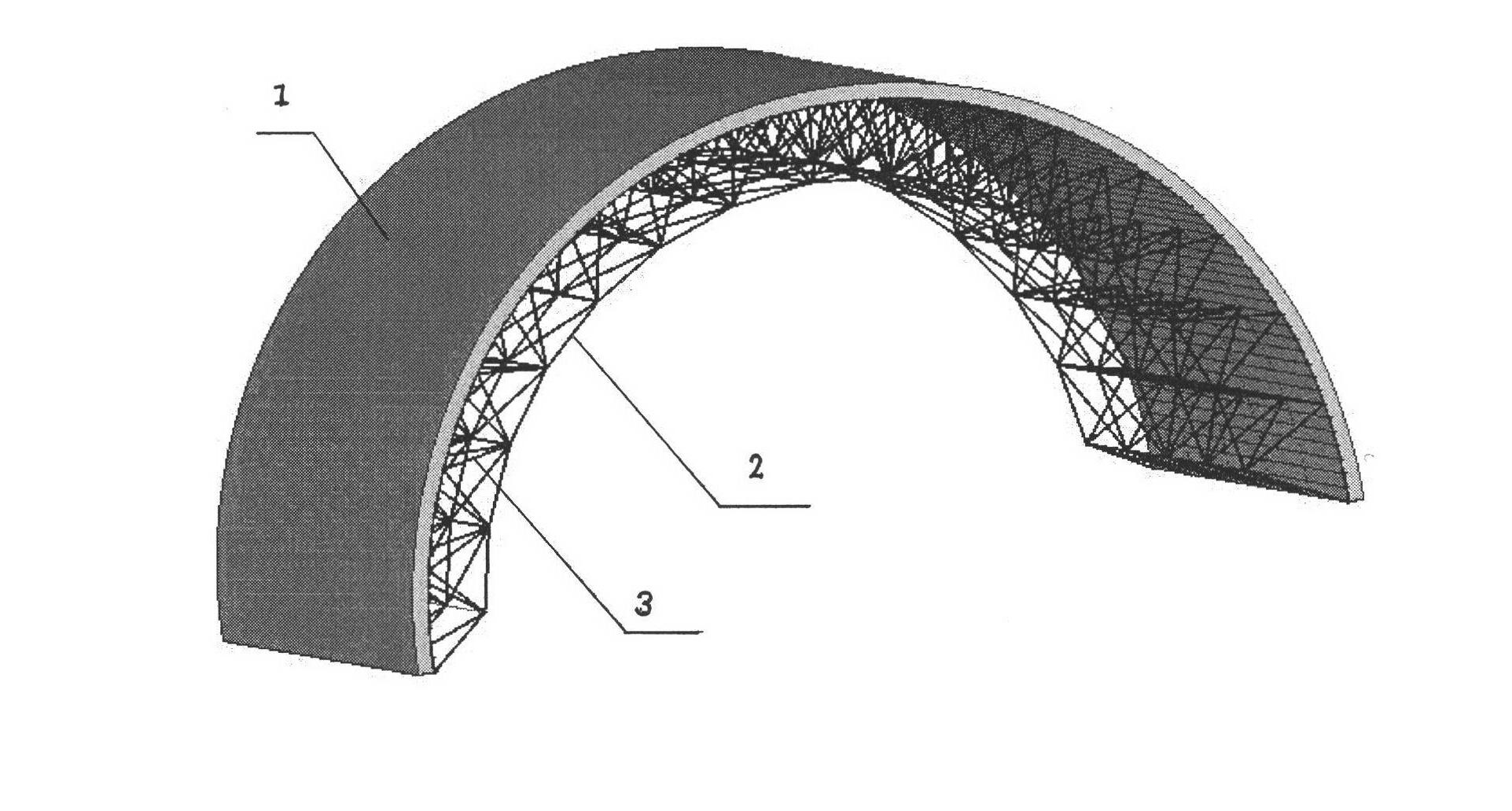

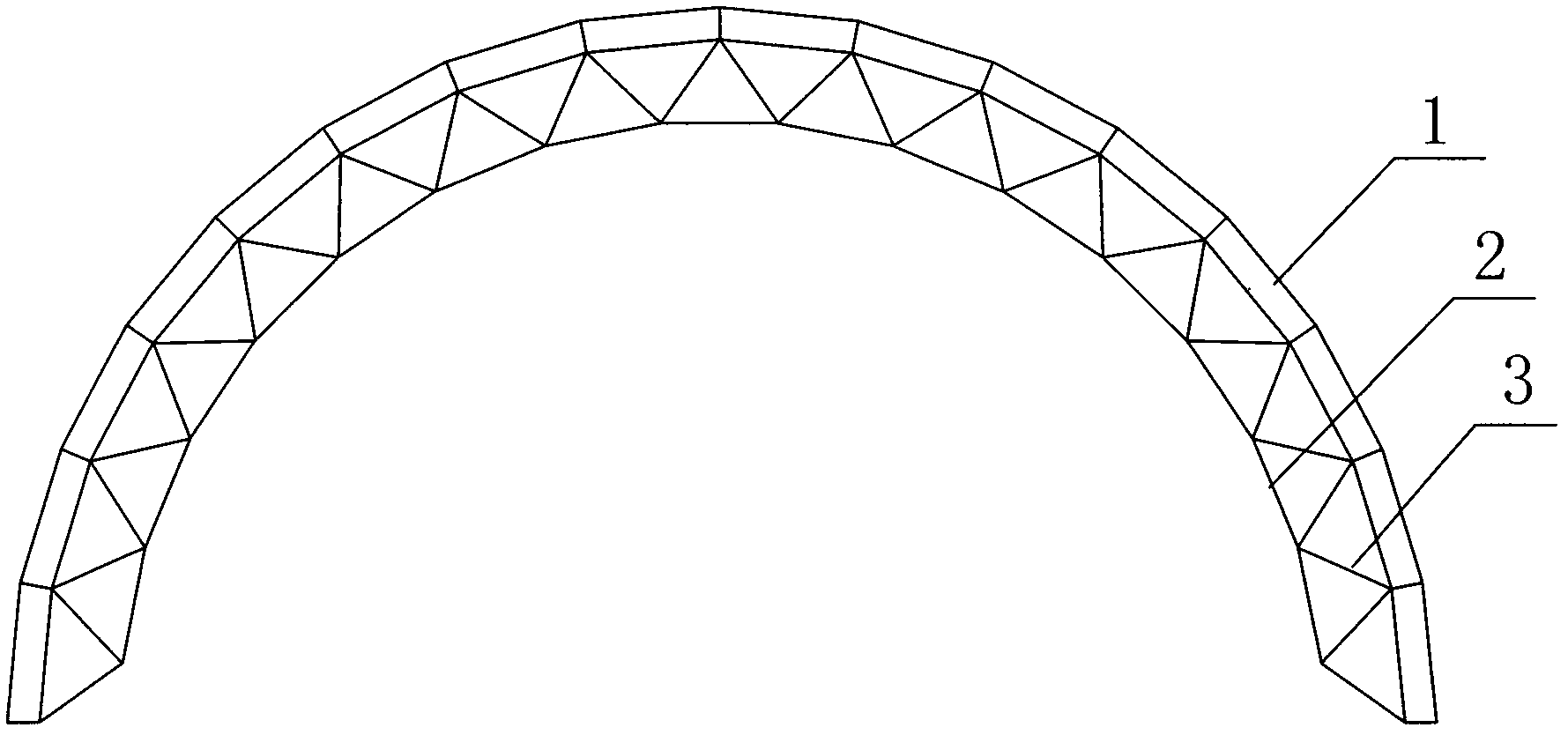

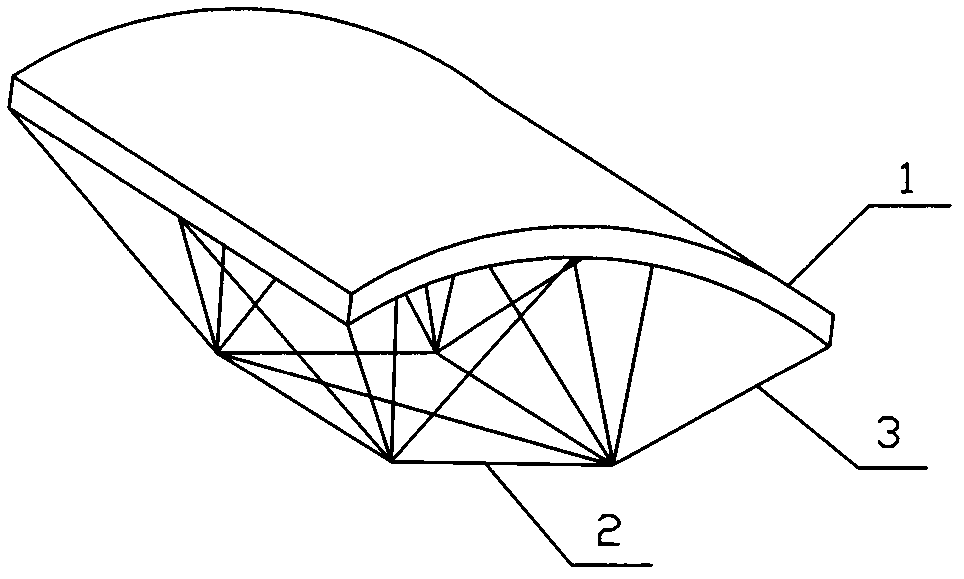

[0023] The schematic diagram of the double-layer cylindrical space combined arch shell structure of the present invention is as follows Figure 1-Figure 7 As shown, it is a double-layer semi-cylindrical surface supported along the two longitudinal sides. It consists of an upper chord cylindrical surface 1, a lower chord cylindrical surface 2, and a space reticulated shell structure 3 connecting the upper chord cylindrical surface and the lower chord cylindrical surface. The lower chord cylindrical surface 2 is formed by connecting the lower chord steel pipe members. The space reticulated shell structure 3 connecting the upper chord cylindrical surface and the lower chord cylindrical surface is a four-sided cone support system formed by connecting webs 5 . The two-way steel rib plate-concrete composite plate module 4 is composed of ribbed st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com