Photovoltaic honeycomb component module

A honeycomb component and photovoltaic technology, applied in the field of photovoltaic honeycomb component modules, can solve problems such as diode heat dissipation, and achieve good waterproof and sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

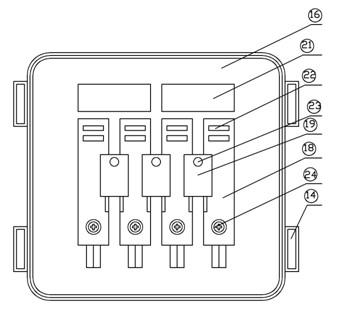

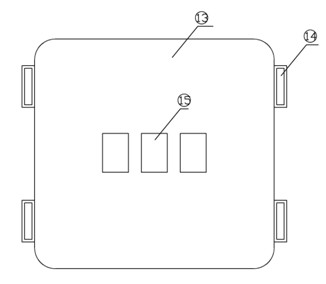

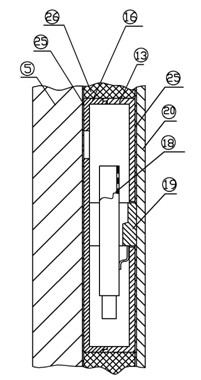

[0034] Such as figure 1 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 with Figure 14 As shown, the photovoltaic honeycomb assembly module in this example includes: the photovoltaic panel 5 on the surface, the aluminum honeycomb core 26, the hot-melt adhesive film 25, and the back aluminum plate 20, which are bonded to each other through the adhesive film 25. After high temperature and high pressure and vacuum lamination, it is installed in a special aluminum alloy frame 7 to form a standard module. There are positive connectors 6 and negative connectors 29 on both sides of the module respectively, and the positive connectors 6 and negative connectors 29 between two adjacent modules can be directly plugged and locked. The interconnected aluminum honeycomb core is like countless I-beams, and the core layer is distributed and fixed in the entire panel surface, so that the panel has a very high strength structure, flatness, and good thermal insulation per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com