Novel turbo-type pneumatic submersible pump with multiple nozzles

A pneumatic submersible pump and multi-nozzle technology, applied to non-variable pumps, pumps, pump devices, etc., can solve the problems of poor sewage discharge capacity, high cost, short service life, etc., and achieve strong sand discharge capacity and high energy efficiency. The effect of high rate conversion and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

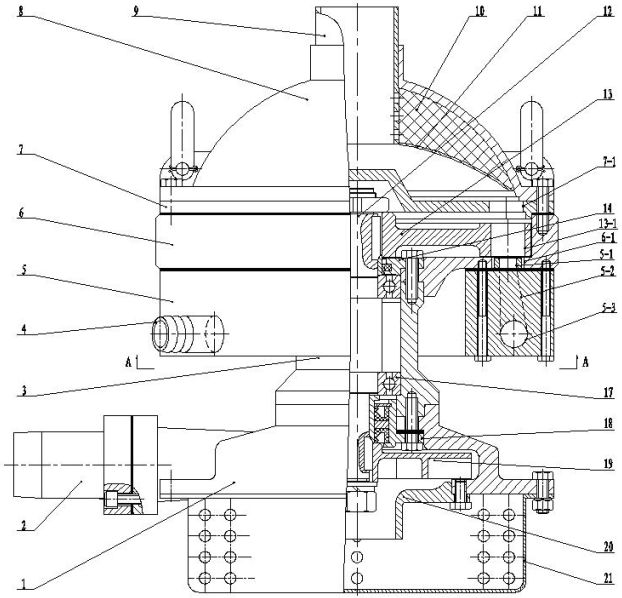

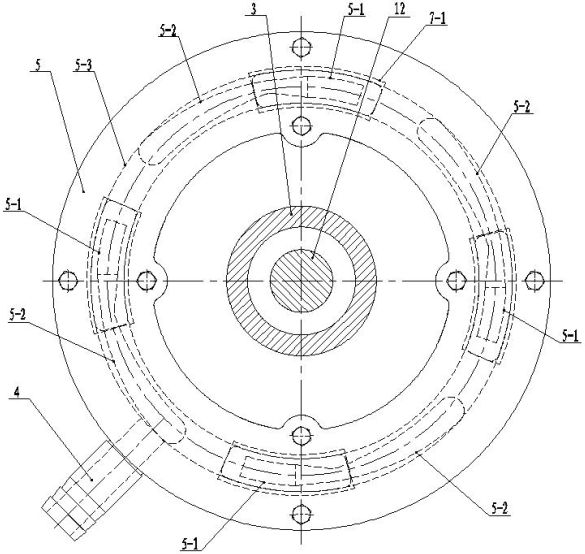

[0017] Such as Figure 1 ~ Figure 4 As shown, a new type of multi-nozzle turbine-type pneumatic submersible pump includes a pump body 1, a bearing housing 3, a turbine housing 6, a turbine cover plate 7, a rotating shaft 12, a turbine 13, a bearing cover 14, a bearing 17, and a sealing seat 18, water wheel 19, pump cover 20, antifouling seat 21, muffler.

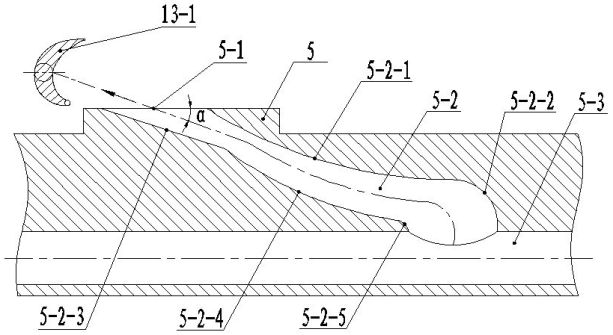

[0018] A water outlet joint 2 is provided on the pump body 1, and the air inlet nozzle 5 is fixedly connected to the lower end surface of the turbine casing 6, and the air inlet pipe 4 is fixedly connected to the circumferential outer surface of the air inlet nozzle 5, and the inside of the air inlet nozzle 5 There is a main air flow channel 5-3, and the main air flow channel 5-3 extends upward evenly with N sub-air flow channels 5-2. In this embodiment, N=4, and there are four nozzles 5-1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com