Lateral entering type backlight module

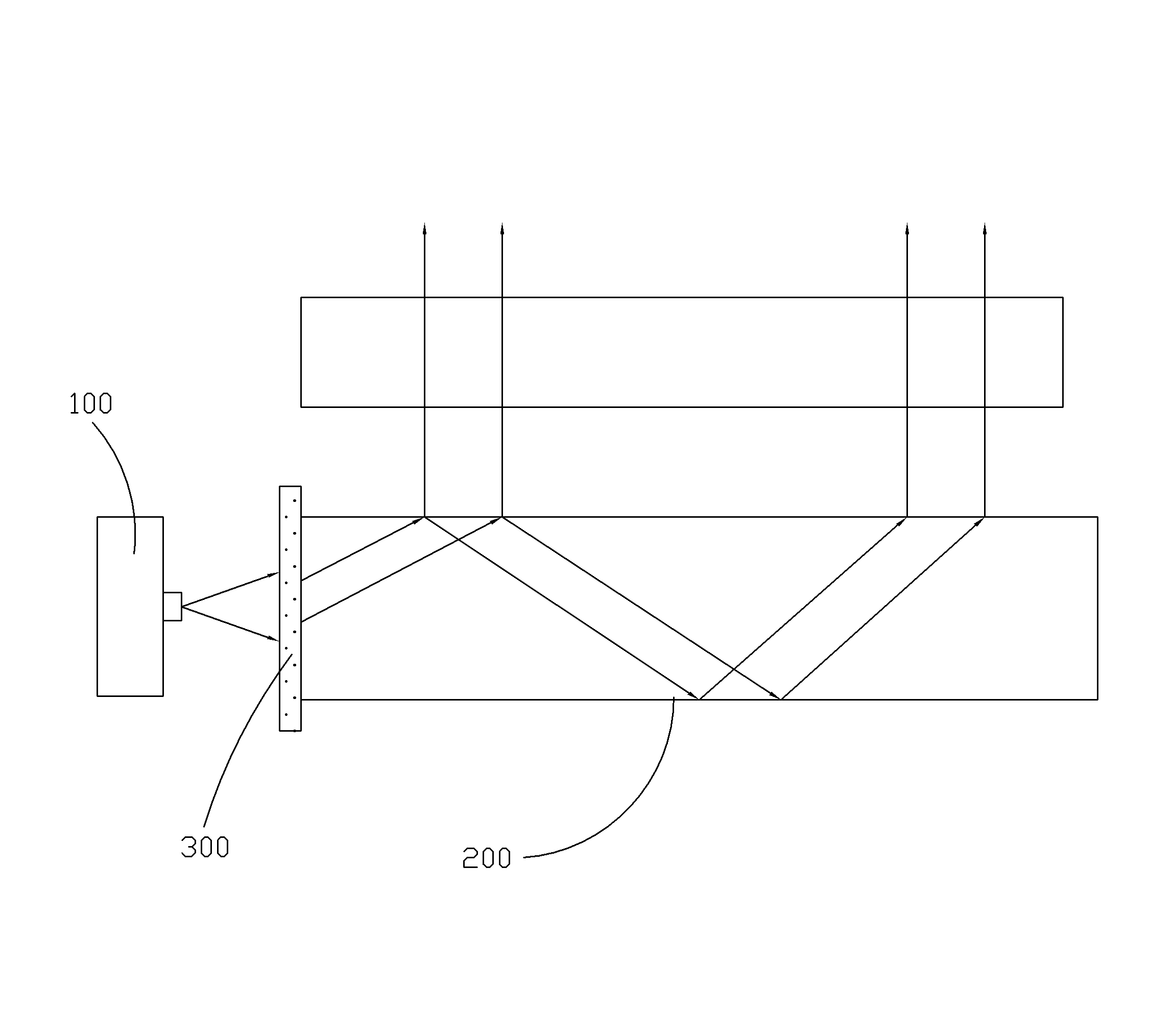

A side-entry backlight and module technology, which is applied in the field of side-entry backlight modules, can solve the problems of reducing uniformity, affecting the light intensity of the module, and causing light decay, so as to reduce the degree of color shift, uniformly disperse light, and Reduce the effect of hotspots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

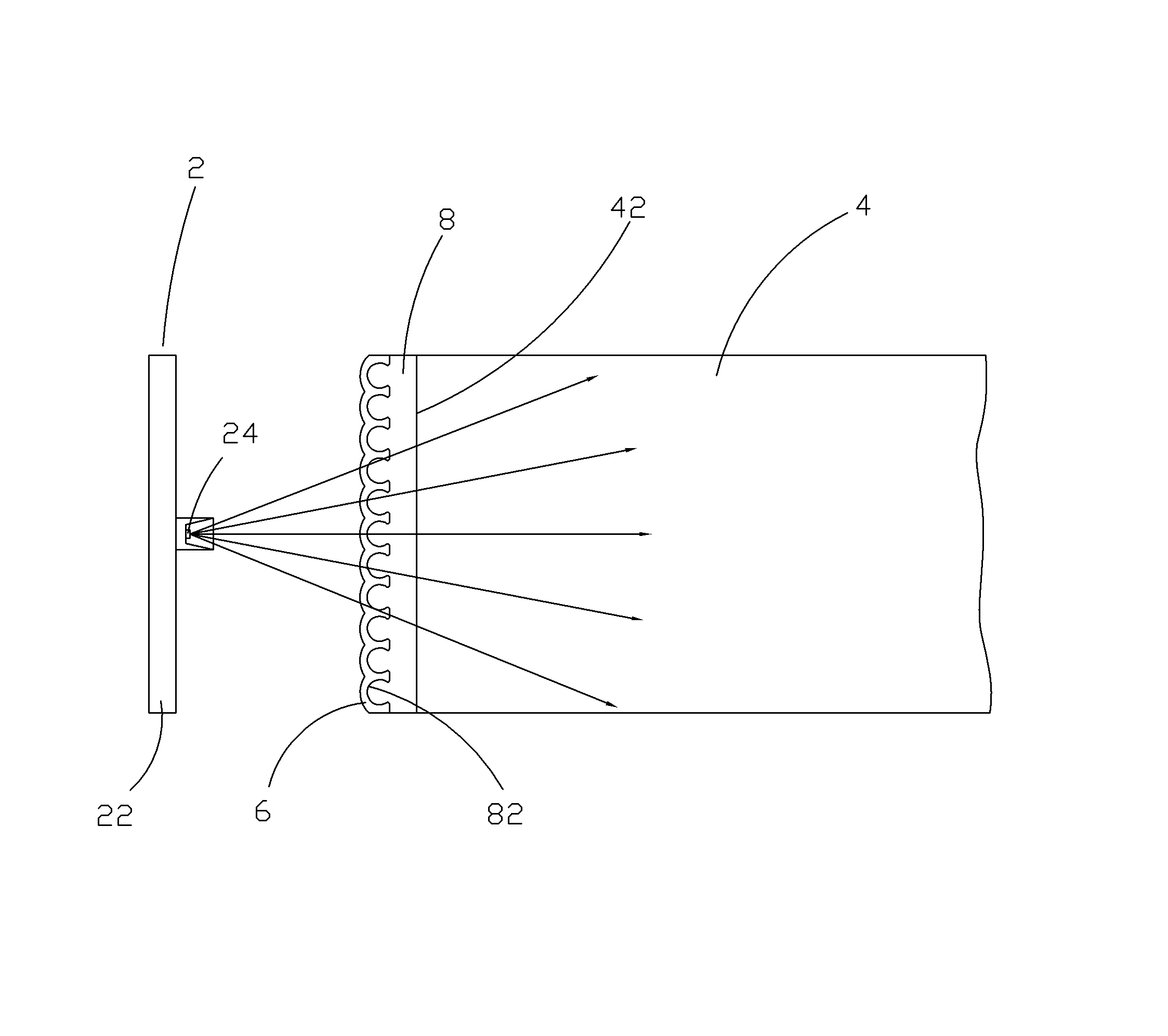

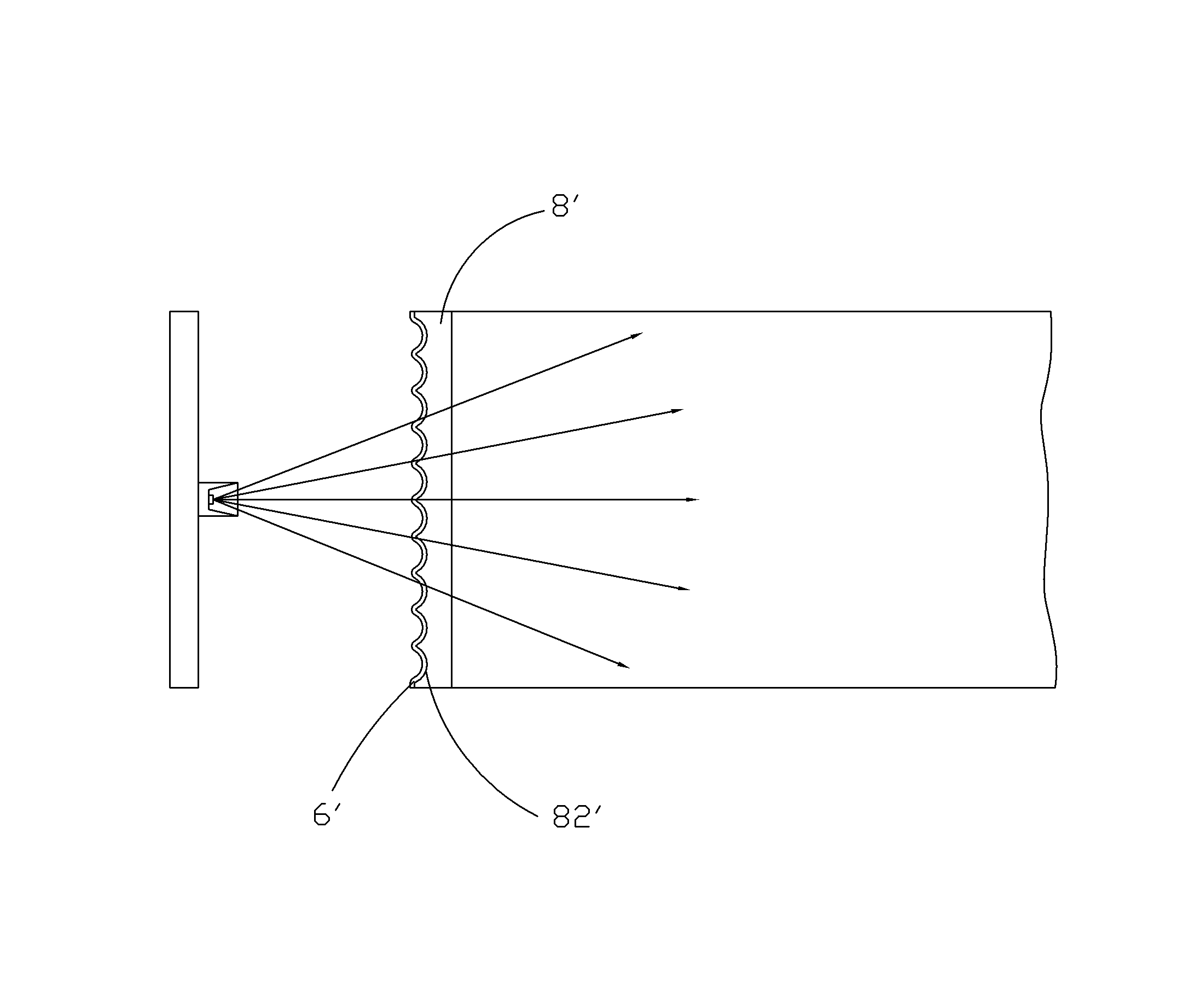

[0021] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0022] Such as figure 2 As shown, the side-type backlight module provided by the present invention includes: a backlight 2 for emitting blue light, a light guide plate 4, and a phosphor layer 6, the light guide plate 4 includes a light incident surface 42, and the phosphor layer 6 is arranged on the light incident surface 42 of the light guide plate 4 through an adhesive layer 8. The backlight source 2 preferably includes a circuit board 22, and several lamps for emitting blue light that are arranged on the circuit board 22 and are electrically connected to the circuit board 22. The LED chips 24 and the backlight 2 are arranged on the side of the light guide plate 4 corresponding to the light incident surface 42 , and several LED chips 24 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com