Reflector, backlight module and television set

A technology of backlight module and reflector, which is applied in the field of television, can solve the problems of insufficient light mixing distance, large loss of light source, and large light emitting angle of LED lights, etc., so as to improve the contrast and resolution of dynamic areas and improve the utilization rate of light energy , Improve the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

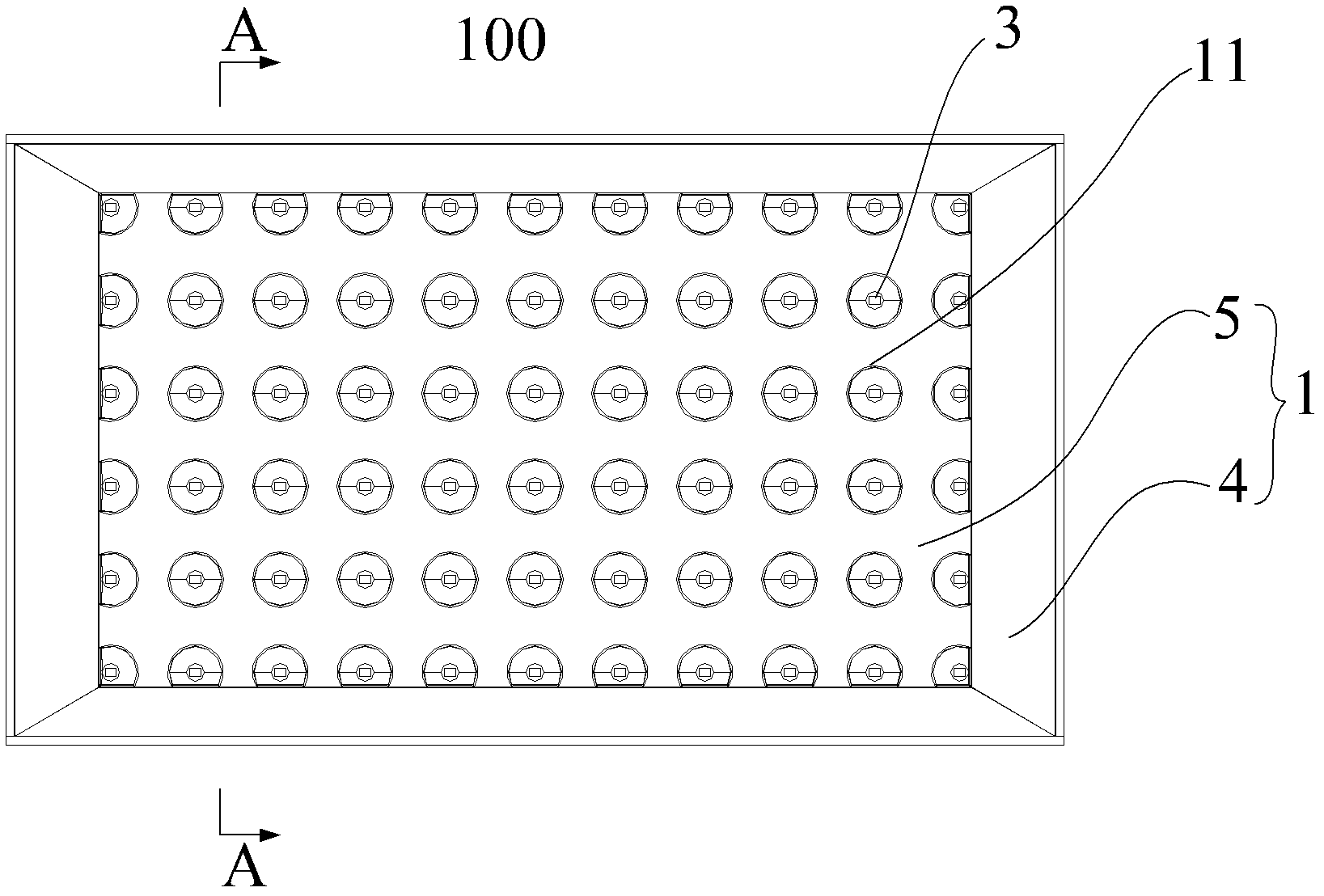

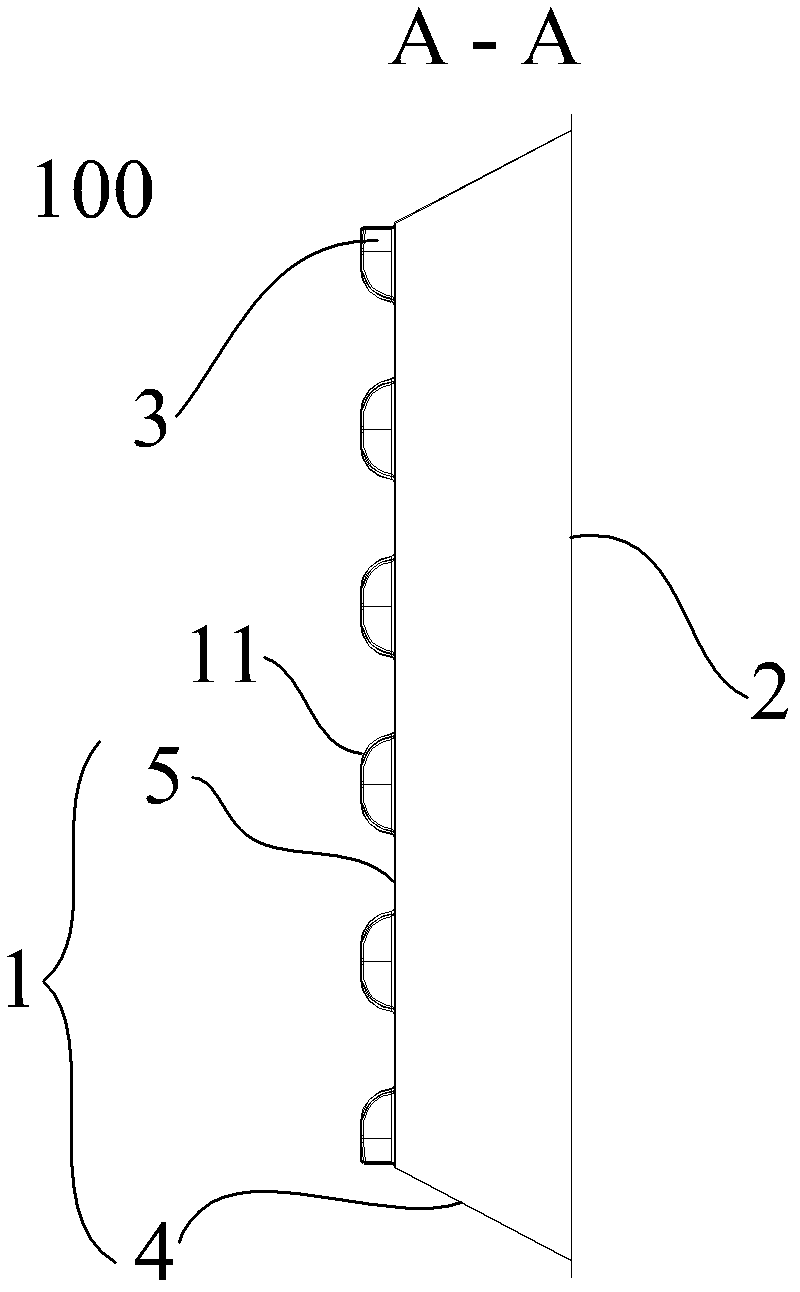

[0032] Figure 1 to Figure 3 A schematic structural view of the backlight module of the present invention is shown.

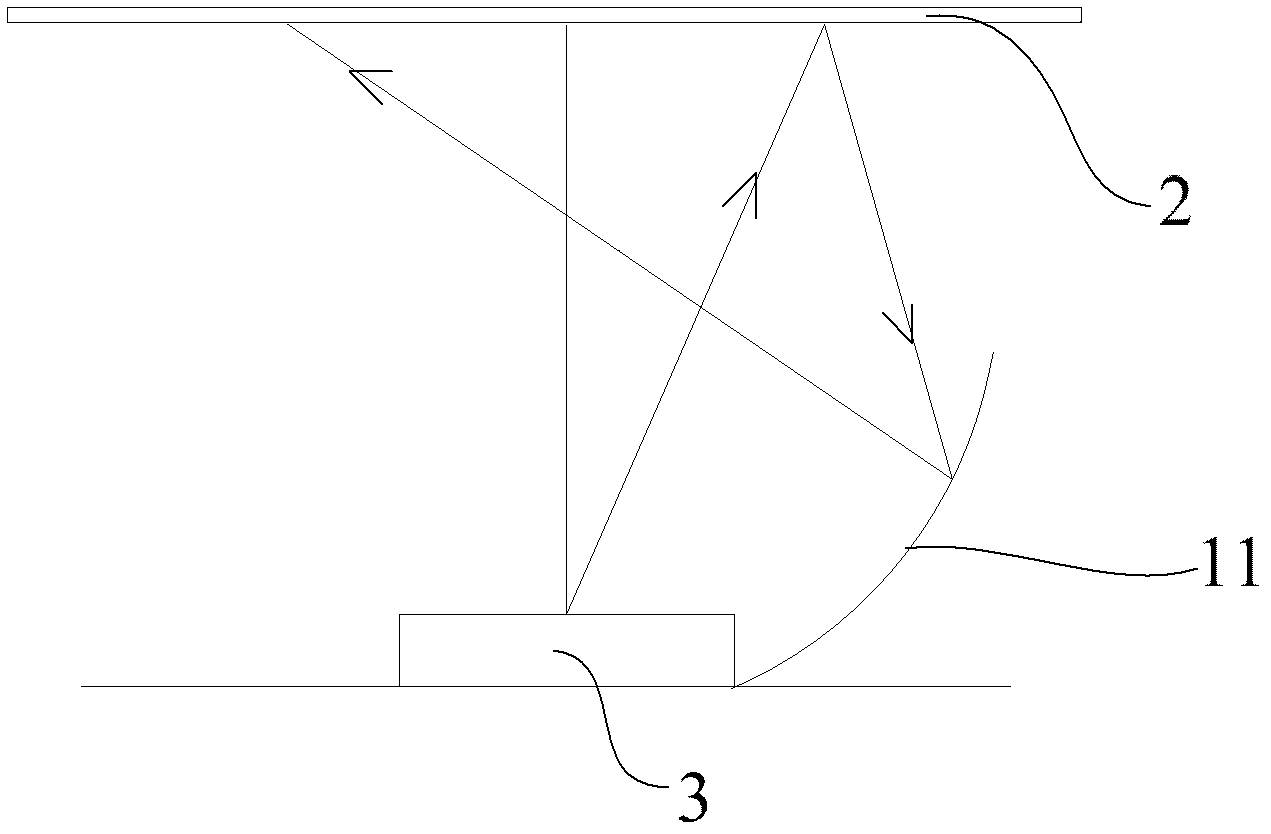

[0033] in, figure 1 is a schematic structural view of an embodiment of the backlight module according to the present invention, figure 2 yes figure 1 Schematic diagram of the sectional view along A-A in the middle, image 3 yes figure 1 Schematic diagram of the effect of the reflector on the light beam shown in .

[0034] Such as Figure 1 to Figure 3 As shown, the present invention also provides a backlight module 100, including a diffuser plate 2 and a reflective sheet, the bottom of the groove 11 of the reflective sheet is provided with a light-emitting element 3, and the opening end of the groove 11 faces the diffuser plate.

[0035] A reflective sheet provided by the present invention includes a reflective sheet body 1 , the reflective sheet body 1 includes a reflective sheet body bottom 5 and a reflective sheet body side 4 , and the reflective she...

Embodiment 2

[0079] The present invention also provides a TV (not shown in the figure), including the above-mentioned backlight module 100 .

[0080] Aiming at the problems existing in the current TV backlight module, the present invention proposes a plan to optimize the reflection sheet from a planar state to a three-dimensional foaming type.

[0081] In this program, the most critical points are:

[0082] The reflective sheet provided by the present invention includes a reflective sheet body 1 , and a groove 11 is provided at the bottom 5 of the reflective sheet body.

[0083] Preferably, the bottom 5 of the reflecting sheet body and the groove 11 are integrally formed by foaming.

[0084] Such as image 3 As shown, the present invention utilizes the contraction of the light beam divergence angle by each foaming groove 11 to increase the light effect within a small area of each lamp, thereby increasing the light effect of the entire backlight.

[0085] After the light emitted by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com