System for precisely measuring phase delay of wave plate and implementation method of system

A technology for precision measurement and wave plate phase, which is applied in the direction of testing optical performance, etc., can solve the problem that the first-order effect of azimuth angle cannot be completely eliminated, the azimuth angle of the polarizer is no longer symmetrical, and it is difficult to accurately calibrate the initial position of the azimuth angle of the polarizer, etc. Problems, achieve the effect of low experimental conditions and environmental requirements, wide application range, and improved measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The inventive point of the present invention is to adopt the self-calibration method to avoid the calibration of the compensator (or standard wave plate), and eliminate the complicated and inaccurate influence of its calibration; adopt the three-region measurement method to reduce the polarization elements in the system (all The influence of the azimuth error of the polarizer and the wave plate) on the measurement accuracy finally realizes the high-precision measurement of the wave plate with any phase delay of multiple wavelengths in a wide spectral range.

[0041] Firstly, the present invention needs to establish a precision measurement system for wave plate phase delay, and then achieve the purpose of the present invention through technical solutions such as self-calibration method and three-region measurement method.

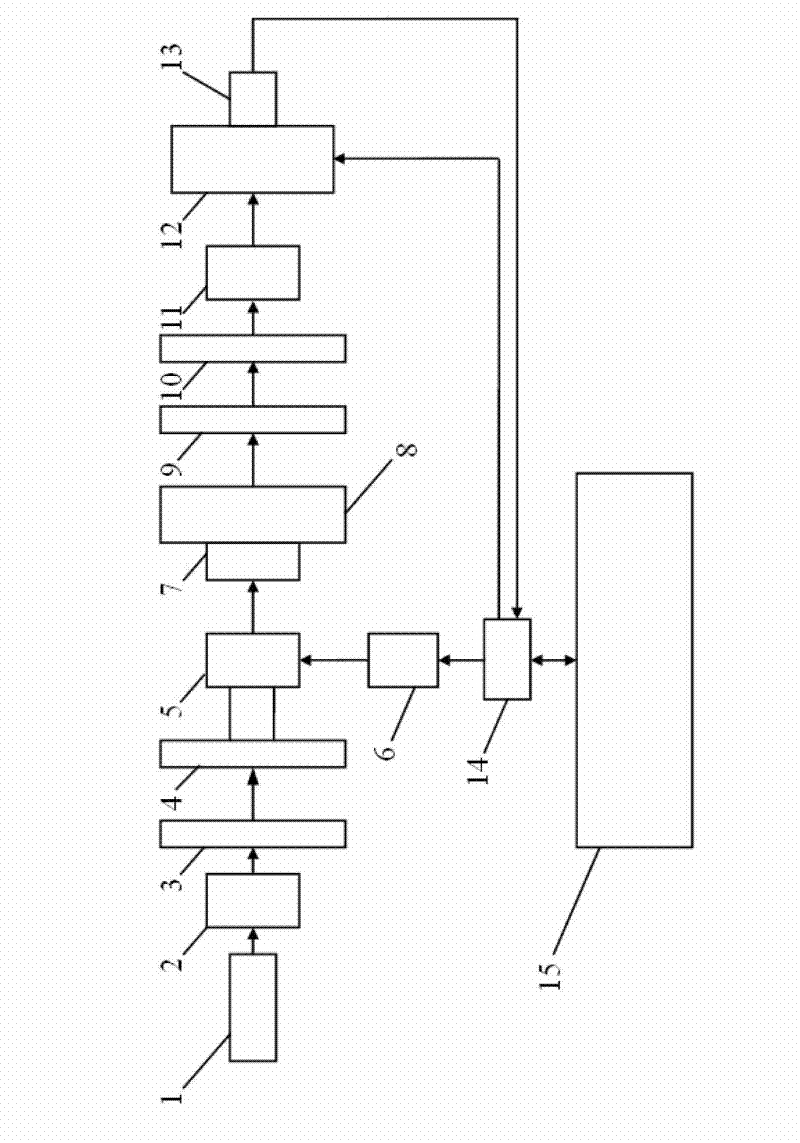

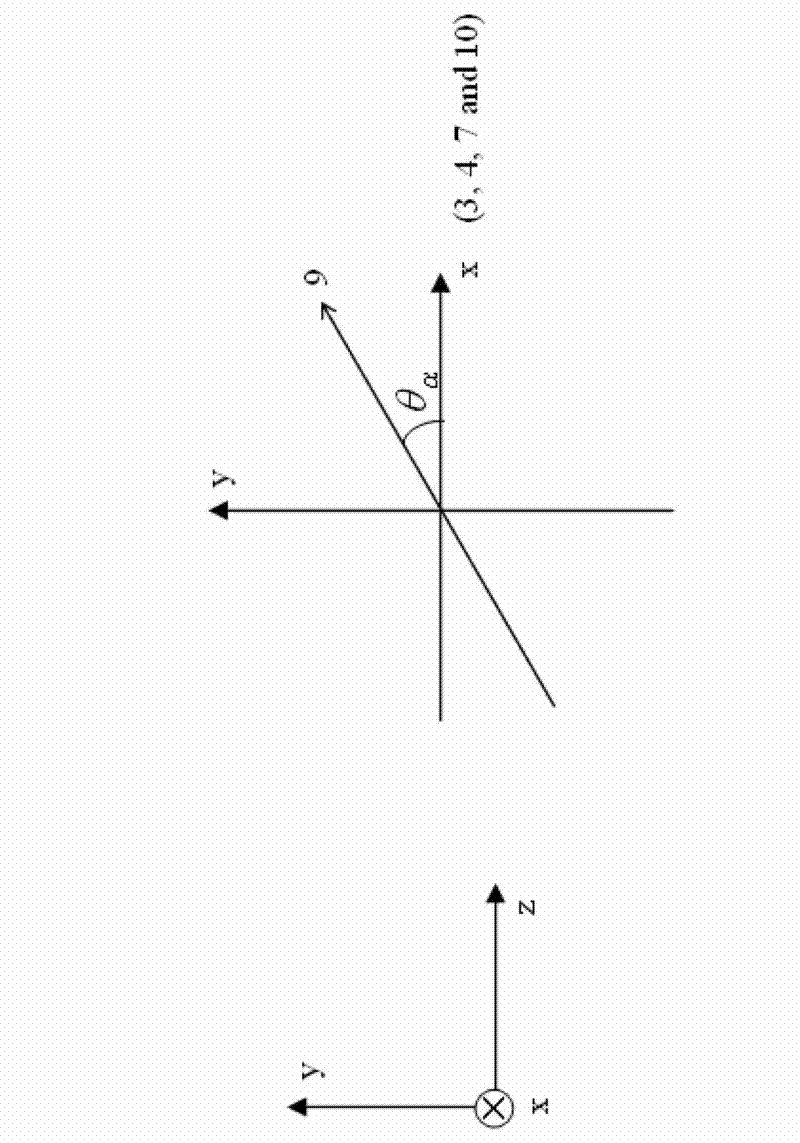

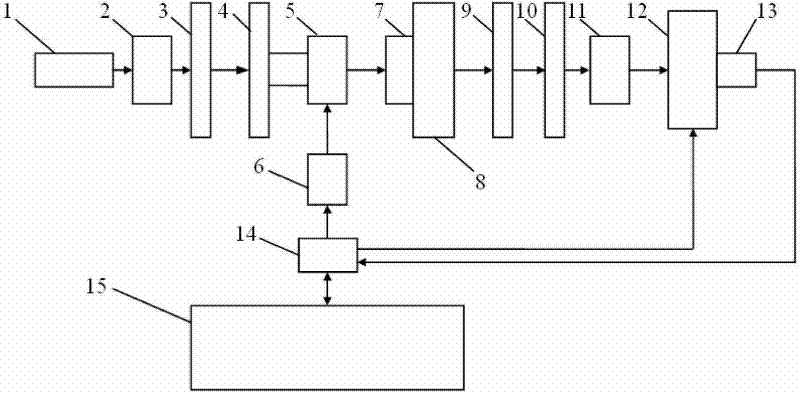

[0042] Such as figure 1 As shown, the composition of the precision measurement system of the wave plate phase delay of the present invention is: a lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com