Autocollimating type confocal method for measuring focal length of lens

A technology of confocal lens and measurement method, which is applied in the direction of testing optical performance, etc., can solve problems such as unrealizable and large errors, and achieve the effect of improving the precision of focusing and improving the sensitivity of focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

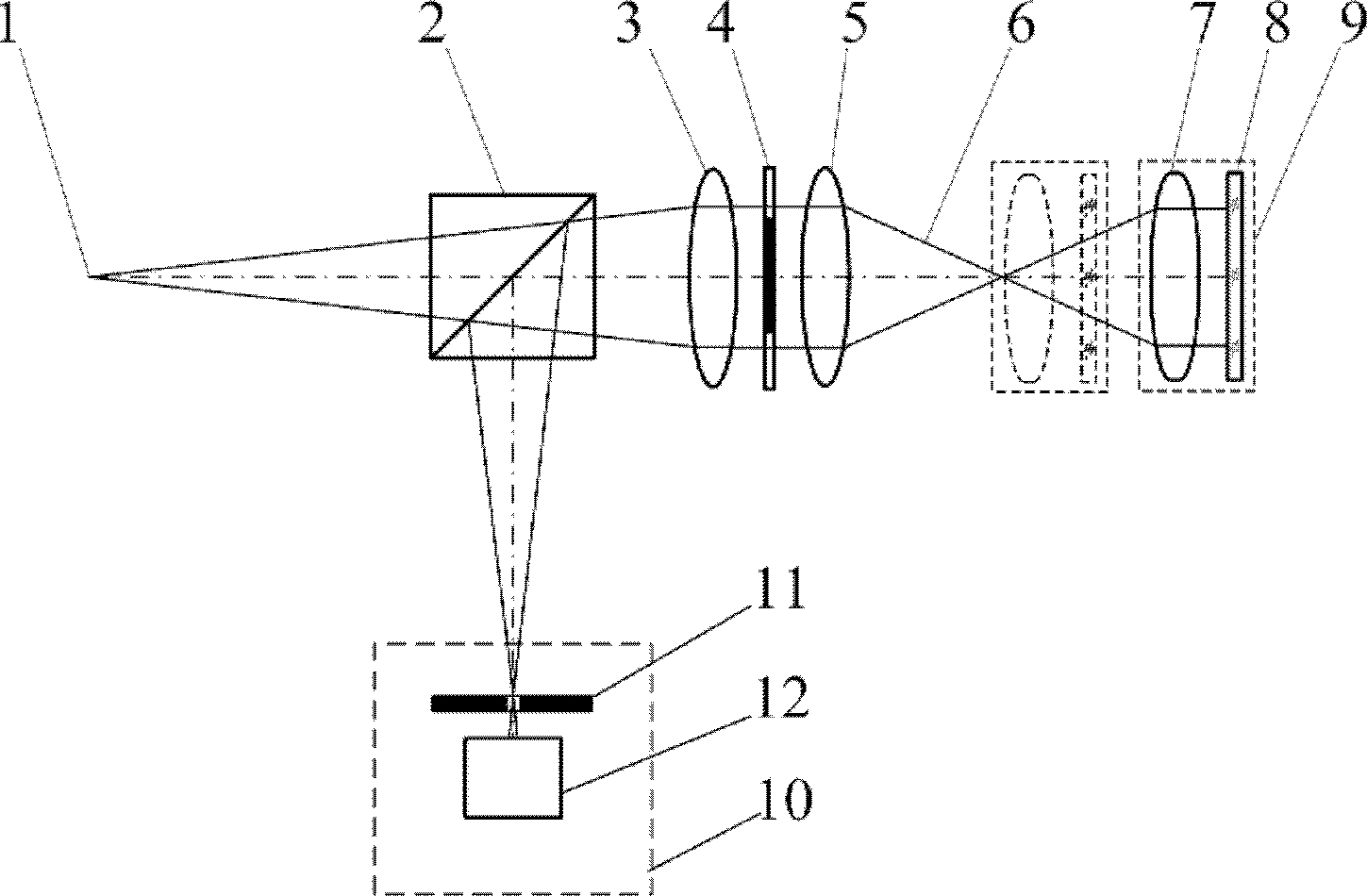

Embodiment 1

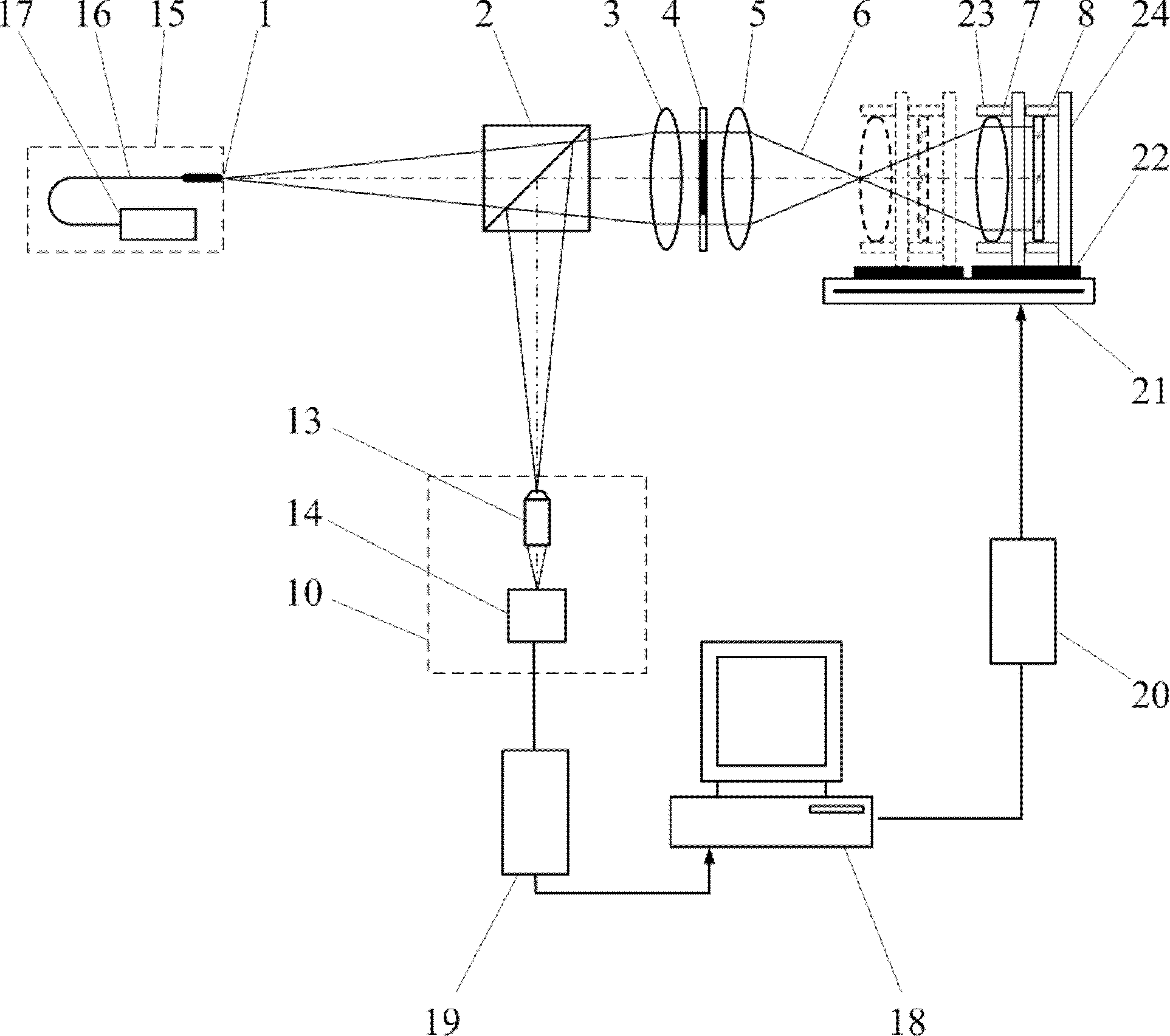

[0037] When the measured lens 7 has a diameter of D=25.4mm and a radius of curvature of the front surface r 1 =90.1mm, the radius of curvature of the back surface r 2 =-115.4mm, material is K9 glass, thickness b=4mm, nominal focal length and top focal length are f′=99mm, l F ′=97.5mm convex lens, the focal length measurement device of self-collimating confocal lens such as figure 2 As shown, the measurement steps are:

[0038] (a) Start the measurement software in the main control computer 18, turn on the laser 17, and the light emitted by the laser 17 is transmitted through the optical fiber 16 to form a point light source 1. The light emitted by the point light source 1 forms a parallel beam after passing through the beam splitter 2 and the collimating lens 3, and the parallel beam is converged by the converging lens 5 to form a measuring beam 6;

[0039] (b) The measured lens 7 is placed on the four-dimensional adjustment frame 23, the auxiliary plane mirror 8 is placed...

Embodiment 2

[0046] According to the radius of curvature r of the front surface of the measured lens 7 1 =90.1mm, the radius of curvature of the back surface r 2 =-115.4mm, refractive index n=1.5163, thickness b=4mm, and the top focal length l of the lens measured in Example 1 F '=97.5316mm, the focal length of the measured lens 7 can be measured indirectly:

[0047] f ′ = l F ′ + r 2 b n ( r 2 - r 1 ) + ( n - 1 ) b = 99.0216 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com