Asphalt mixture pressure type permeameter and method for measuring permeability

An asphalt mixture and permeameter technology, applied in permeability/surface area analysis, measuring devices, scientific instruments, etc., can solve the problems of long time consumption, poor reproducibility, large deviation of test results of asphalt mixture permeameter, etc., and achieve the test time. The effect of shortening, small test volume, and short working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

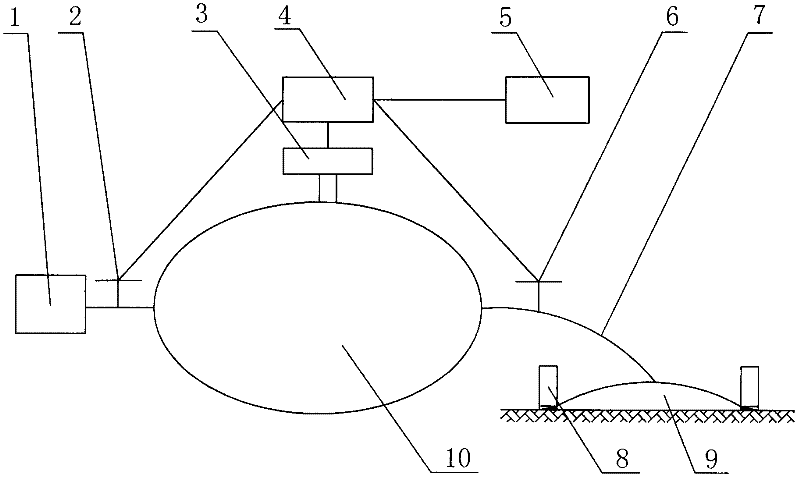

[0047] see figure 1 , the asphalt mixture air pressure type permeation instrument of the present invention is composed of an inflator 1, an electromagnetic inlet valve 2, a pressure sensor 3, a controller 4, a timing device 5, an electromagnetic outlet valve 6, a conduit 7, a counterweight 8, a sealing cover 9. The air storage bag 10 is connected and formed.

[0048]An electromagnetic intake valve 2 is arranged at the air intake end of the air storage bag 10, and the air storage bag 10 communicates with the inflator 1 through the conduit 7. The inflator 1 of the present embodiment selects an air compressor to compress the air and output it to the air storage bag 10. An electromagnetic outlet valve 6 is arranged at the air outlet end of the air storage bag 10, and communicates with the top of the sealing cover 9 through the conduit 7. The vertical section of the sealing cover 9 is arc-shaped, and the whole is in the shape of a spherical crown. The sealing cover 9 is arranged o...

Embodiment 2

[0059] The asphalt mixture air pressure type permeameter in this embodiment is composed of an inflator 1, an electromagnetic inlet valve 2, a pressure sensor 3, a controller 4, a timing device 5, an electromagnetic outlet valve 6, a conduit 7, a counterweight 8, a sealing The cover 9 and the air storage bag 10 are connected to form.

[0060] The timing device 5 of the present embodiment adopts a stopwatch and is manually controlled. Other components and the coupling relationship of the components are the same as in Embodiment 1. The working principle of this embodiment and the testing method of the permeability of asphalt mixture are the same as those of Embodiment 1.

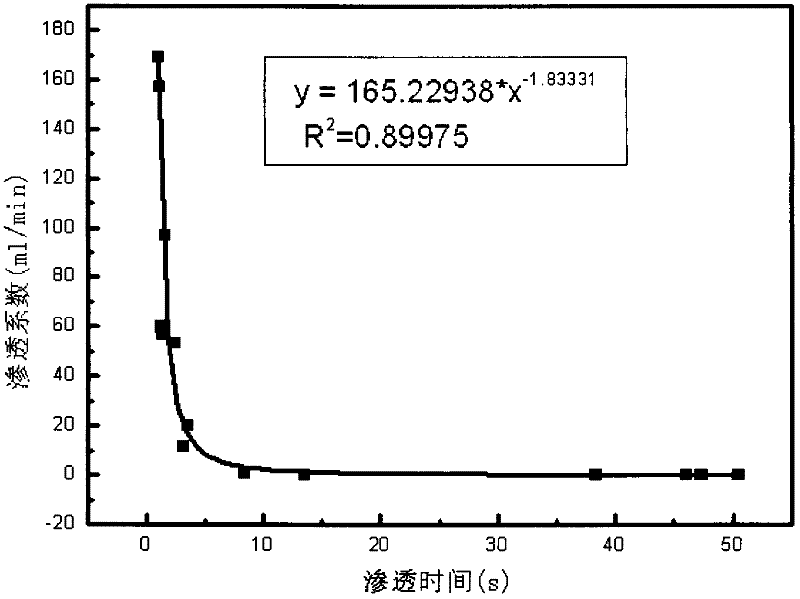

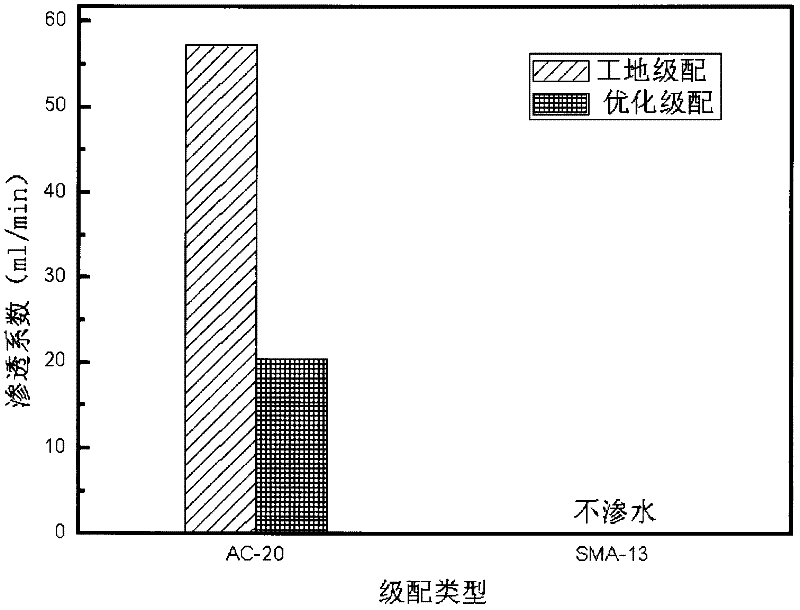

[0061] In order to verify the beneficial effect of the present invention, the inventor has adopted the asphalt mixture air pressure type permeameter prepared in Example 1 of the present invention and the asphalt mixture permeability test method and the water seepage detection method in the prior art to carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com