Special gamma scanning measuring system for hot chamber and installation method thereof

A measurement system and a hot cell technology, applied in the field of gamma scanning measurement systems, can solve the problems of inability to install a gamma spectrometer detector, inability to complete gamma scanning measurement, large size of a square fuel assembly, etc., so as to avoid external interference, have a simple structure, Automatic running smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further elaborated below in conjunction with the accompanying drawings.

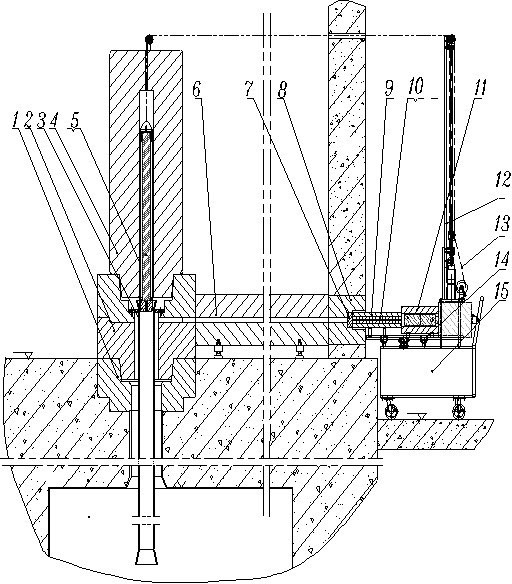

[0043] Such as figure 1 As shown, a γ-scanning measurement system dedicated to a hot cell includes a hoisting tunnel 1 in the hot chamber, a lead tank support 2 is installed on the hoisting tunnel 1, and a guide cylinder 3 passes through the lead tank support 2 and the hoisting tunnel 1 go deep into the inside of the hot chamber and be fixedly connected with the lead tank support 2. The gamma scanning measurement system also includes a shielded transfer container 4, the above-mentioned shielded transfer container 4 is installed above the lead tank support 2, and inside the shielded transfer container 4 is Hanger 5, the above-mentioned hanger 5 can move up and down in the lead tank support 2, the guide cylinder 3 and the shielding transfer container 4; a collimator 6 is installed on one side of the lead tank support 2, and the above-mentioned collimator 6 The ray pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com