Light emitting element

A light-emitting element and light wavelength technology, which is applied in the direction of electrical components, electric solid-state devices, semiconductor devices, etc., can solve the problems of difficulty in meeting the requirements of luminous efficiency, poor color stability of organic light-emitting diodes, etc., and achieve the effect of easy production and stable optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

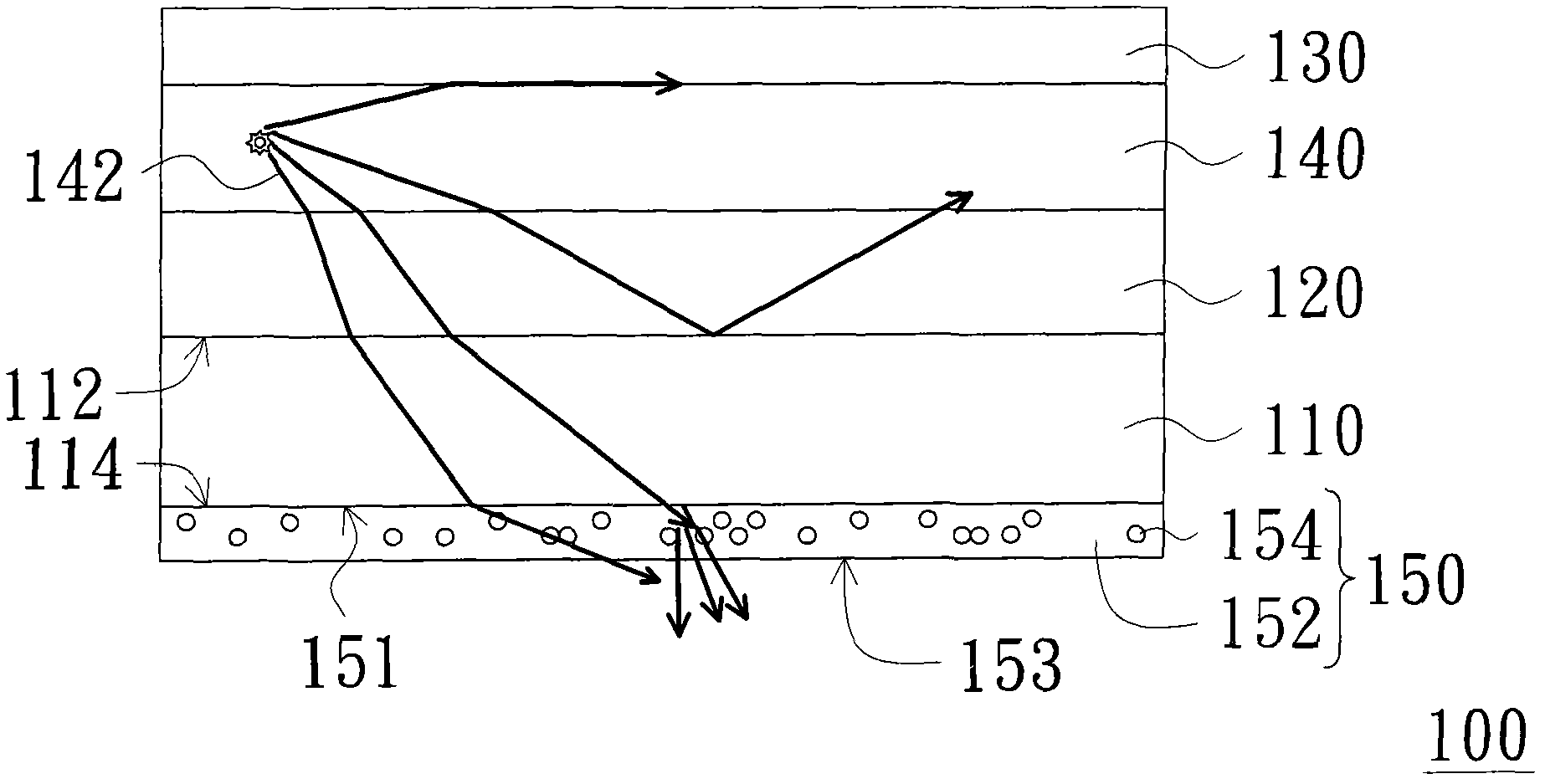

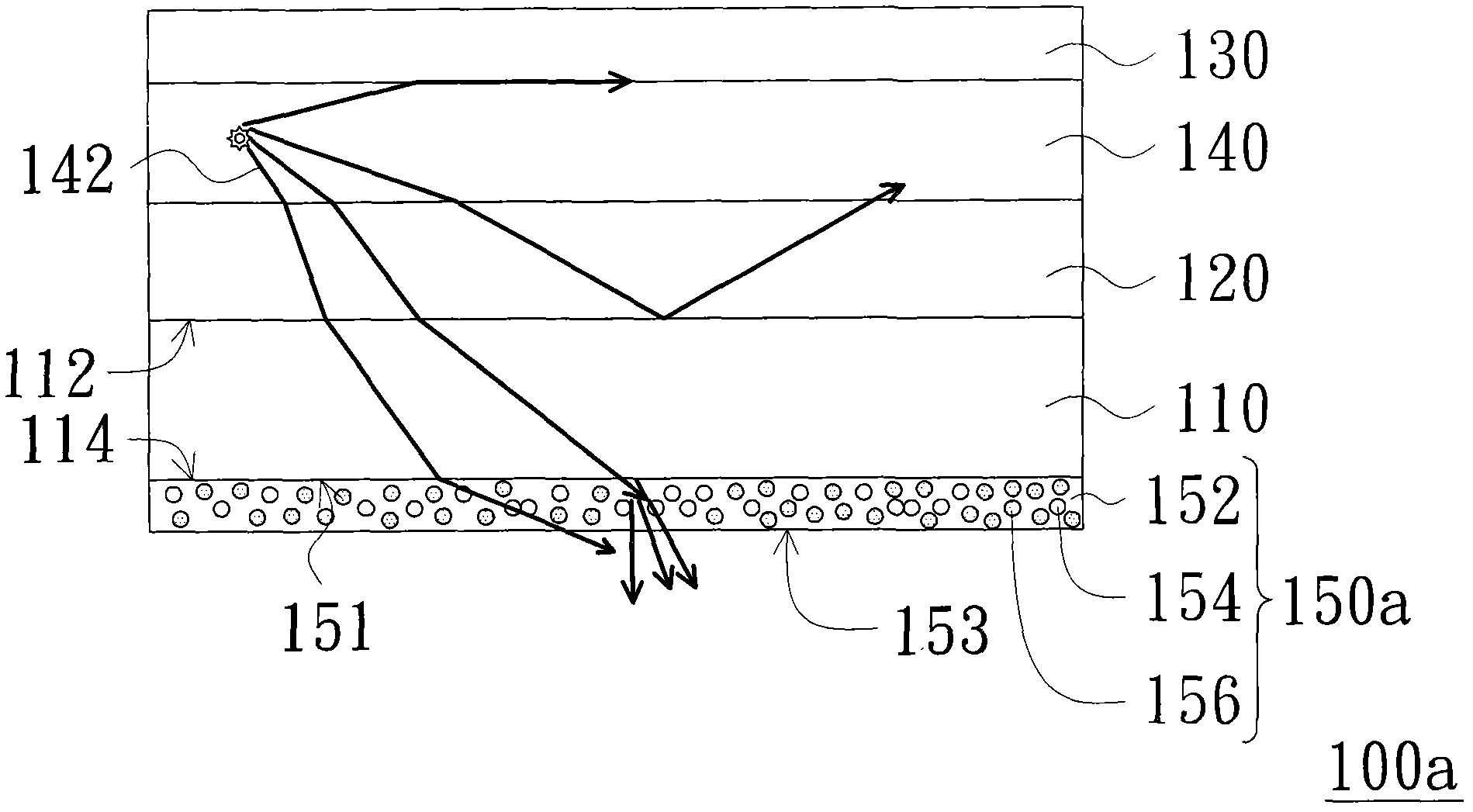

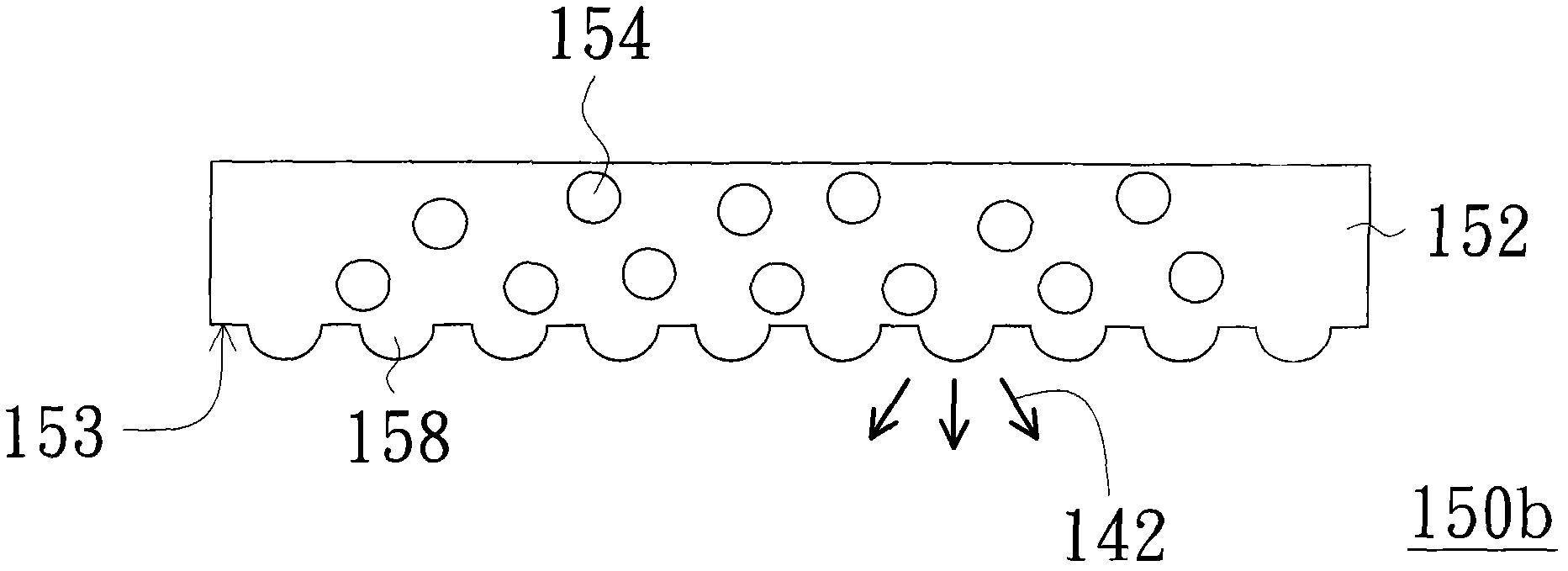

[0032] figure 1 It is a schematic diagram of a light emitting element according to an embodiment of the present invention. Please refer to figure 1 , the light emitting element 100 of this embodiment includes a transparent substrate 110 , a first electrode layer 120 , a second electrode layer 130 , a light emitting layer 140 and a light wavelength adjustment film 150 . The transparent substrate 110 can be a glass substrate or a plastic substrate, but not limited thereto. The transparent substrate 110 has a first surface 112 and a second surface 114 opposite to each other. The first electrode layer 120 is disposed on the first surface 112, and the first electrode layer 120 is a transparent electrode layer, such as an indium tin oxide (ITO) electrode layer or an indium zinc oxide (IZO) electrode layer etc. The second electrode layer 130 is opposite to the first electrode layer 120 , and the first electrode layer 120 and the second electrode layer 130 are positive and negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com