Lubricant composition and sliding mechanism using the lubricant composition

A technology of lubricating oil composition and sliding mechanism, applied in the field of sliding mechanism and lubricating oil composition, can solve problems such as increase in friction coefficient, and achieve the effect of excellent low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] In the preparation of the phosphorus-zinc-containing compound used in the present invention 1, a phosphorus-containing compound represented by the general formula (I) is used.

[0083] [chemical 9]

[0084]

[0085] (I) In the formula, X 1 、X 2 Represents an oxygen atom or a sulfur atom. R 1 Represents an organic group containing an oxygen atom or a sulfur atom and having 2 to 30 carbon atoms. n is an integer selected from 1-3. Especially preferred X 1 、X 2 A compound in which at least one is an oxygen atom.

[0086] Among the phosphorus-containing compounds represented by the formula (I), the phosphorus-containing compound represented by the general formula (III) is particularly preferable.

[0087] [chemical 10]

[0088]

[0089] (III) In the formula, R 4 Represents an organic group having 4 to 24 carbon atoms. R 5 Represents a divalent organic group having 1 to 6 carbon atoms. n is an integer selected from 1-3.

[0090] R 4 The organic group is p...

Embodiment 1~3 and comparative example 1~3

[0204] The lubricating oil composition of Invention 1 and the lubricating oil composition for comparison having the compositions shown in Table 1 were prepared, and the friction characteristic test shown below was carried out to obtain the friction coefficient of the sliding mechanism 1. The results are shown in Table 2.

[0205]

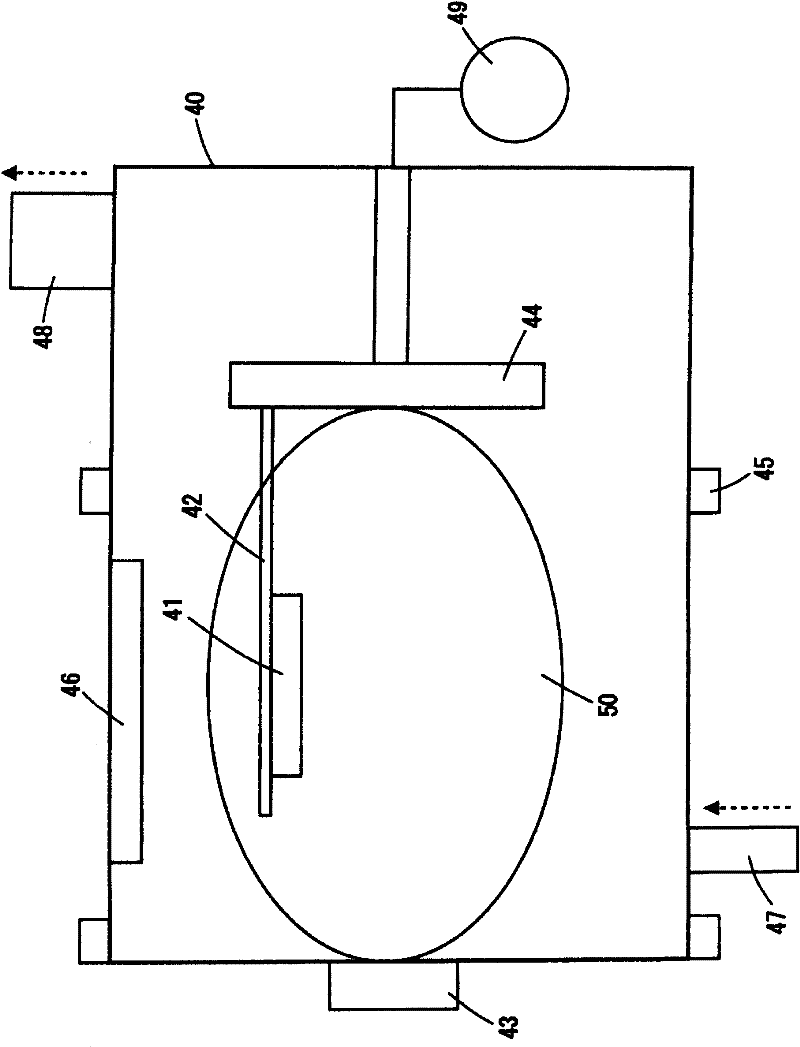

[0206] Using a reciprocating friction tester (SRV reciprocating friction tester manufactured by Optimal Corporation), the friction coefficient of the sliding mechanism 1 was measured by the following method.

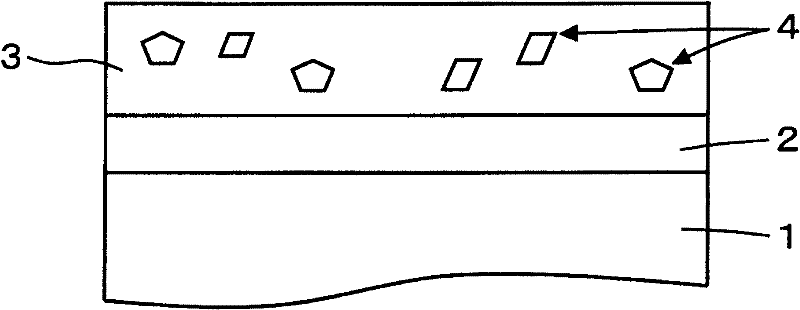

[0207] Disk with DLC coating (graphite crystal particle size: 20nm) As a test piece, several drops of sample oil (lubricating oil composition) were dropped thereon. Cylinder (Cylinder) manufactured in SCM420 The coefficient of friction in the slide mechanism 1 was obtained under the conditions of a load of 400 N, an amplitude of 1.5 mm, a frequency of 50 Hz, and a temperature of 80° C. while being attached to the upper portion of the d...

Embodiment 4、5、 comparative example 4、5

[0236] The friction characteristics are tested in the same way with the lubricating oil and the sliding member as shown below, and the coefficient of friction is obtained. The results are shown in Table 3.

[0237] (1) lubricating oil

[0238] OIL1: Lubricating oil composed of the lubricating oil composition described in Example 1

[0239] OIL2: Lubricating oil composed of the lubricating oil composition described in Comparative Example 1

[0240] (2) Sliding member (test piece)

[0241] As test pieces, the following DLC film-coated discs were used.

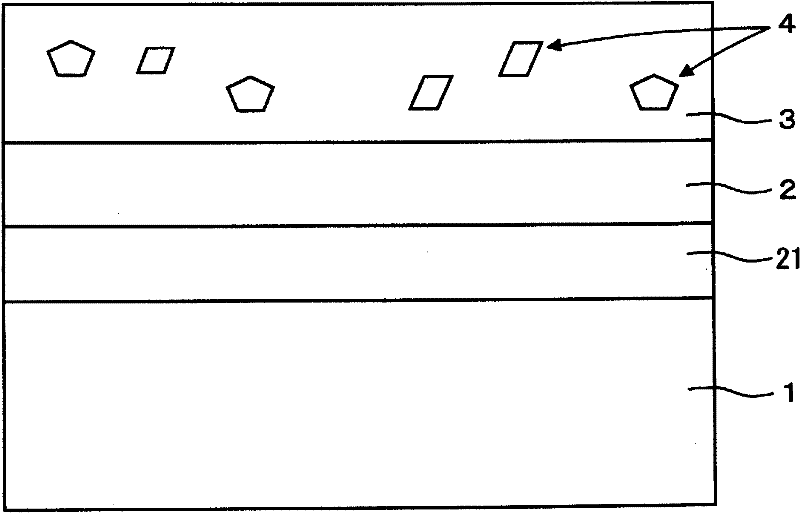

[0242] DLC1: DLC film with graphite crystal peak in X-ray scattering spectrum (graphite crystal particle size: 20nm), hydrogen content 25atom%, made by cathode PIG plasma CVD method.

[0243] DLC2: Hydrogen-containing DLC film without graphite crystal peak in the X-ray scattering spectrum, with a hydrogen content of 30atom%, produced by high-frequency plasma CVD.

[0244] The intermediate layer in the DLC coating consi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com