Corn-harvesting and stalk-chopping test bench

A test bed, corn technology, applied in the direction of harvesters, agricultural machinery and tools, applications, etc., can solve the problems of staying in subjective inference, low seedling emergence rate, grain production reduction, etc., to achieve a large adjustment range, avoid damage, and safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

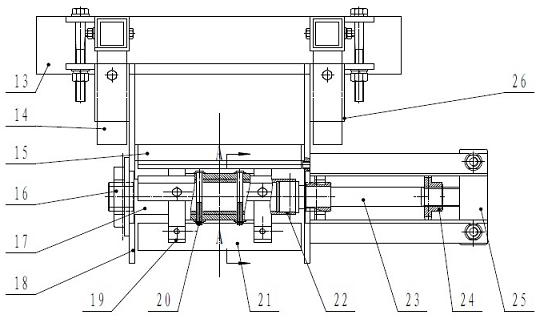

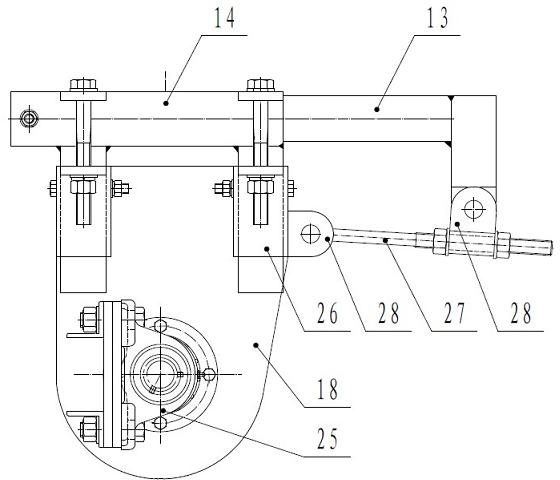

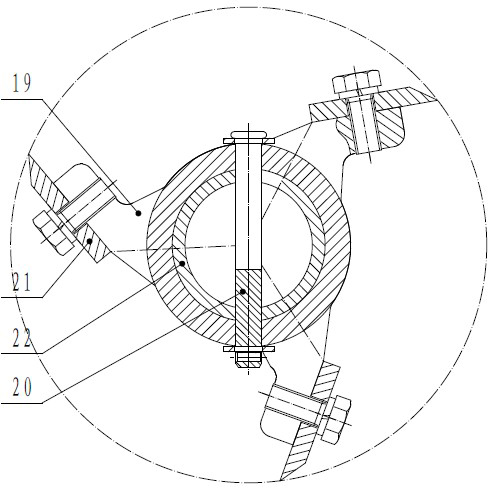

[0019] This embodiment is used to illustrate the present invention, but not to limit the present invention in any way. Such as Figure 1~4 In the illustrated embodiment: the ear picking device (1) is hung on the front of the frame (4) through a pin, the output shaft of the variable frequency speed regulation motor (9) is equipped with a torque sensor (8), and the frequency conversion speed regulation motor ( 9) The power is transmitted to the ear picking device (1) through the universal joint (11) and the drive shaft (12), and the horizontal slice knife shredding device (3) under the ear picking device (1) is hung by U-shaped bolts. Connected to the frame (4), a chain drive is adopted between the ear picking device (1) and the horizontal blade shredding device (3) to realize power transmission, and the variable frequency speed regulating motor (6) drives the hydraulic pump (5) to work , The hydraulic oil in the hydraulic oil tank (7) is discharged into the hydraulic cylinder t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com