Method for reducing production cost of high-end beef

A low-cost, high-end technology, applied in the field of feed nutrition in animal husbandry, can solve the problems of high feeding cost, high market price, and large amount of supplementary feed, so as to achieve broad application prospects, reduce production costs, and broaden feed The effect of raw material source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

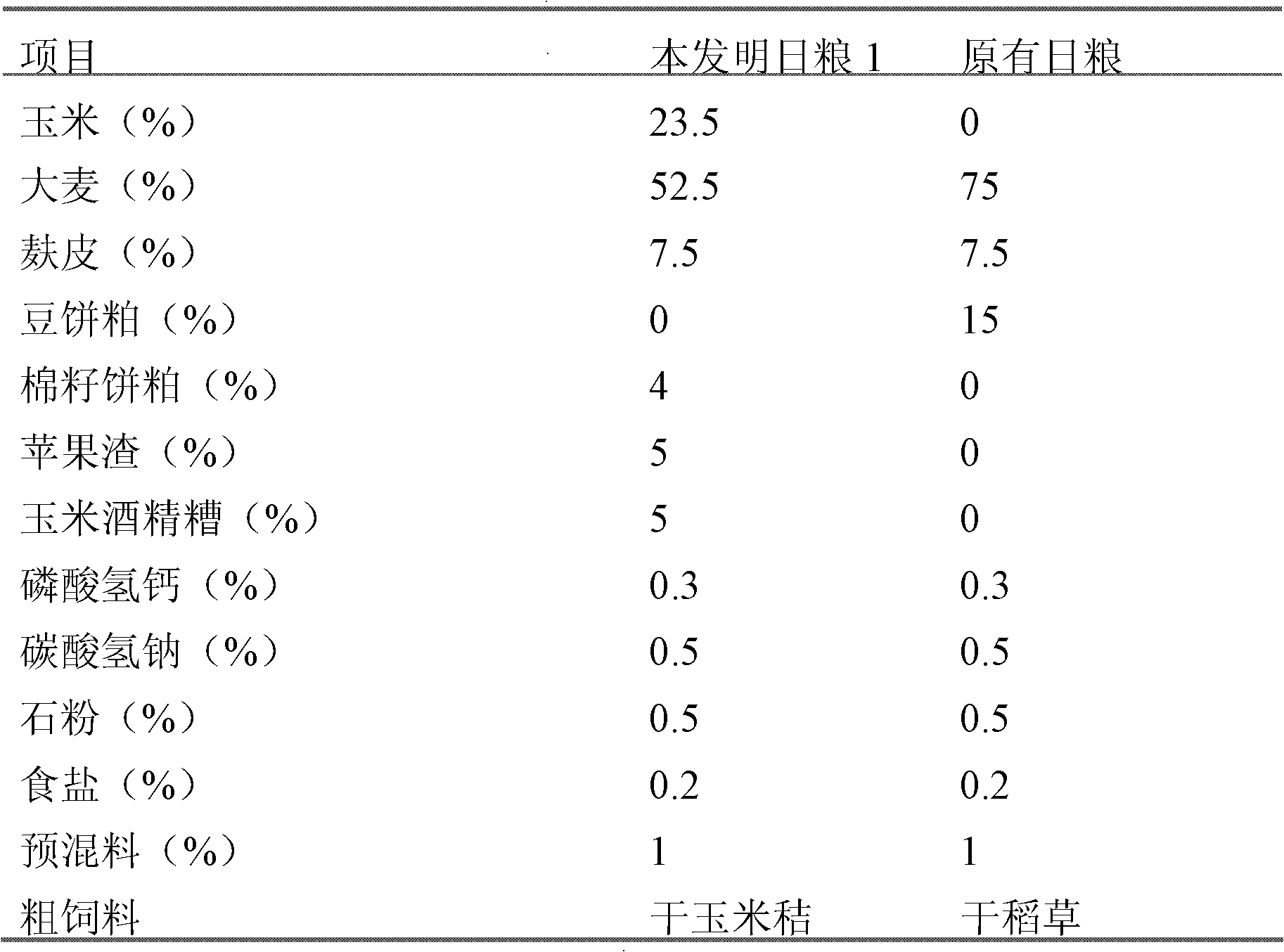

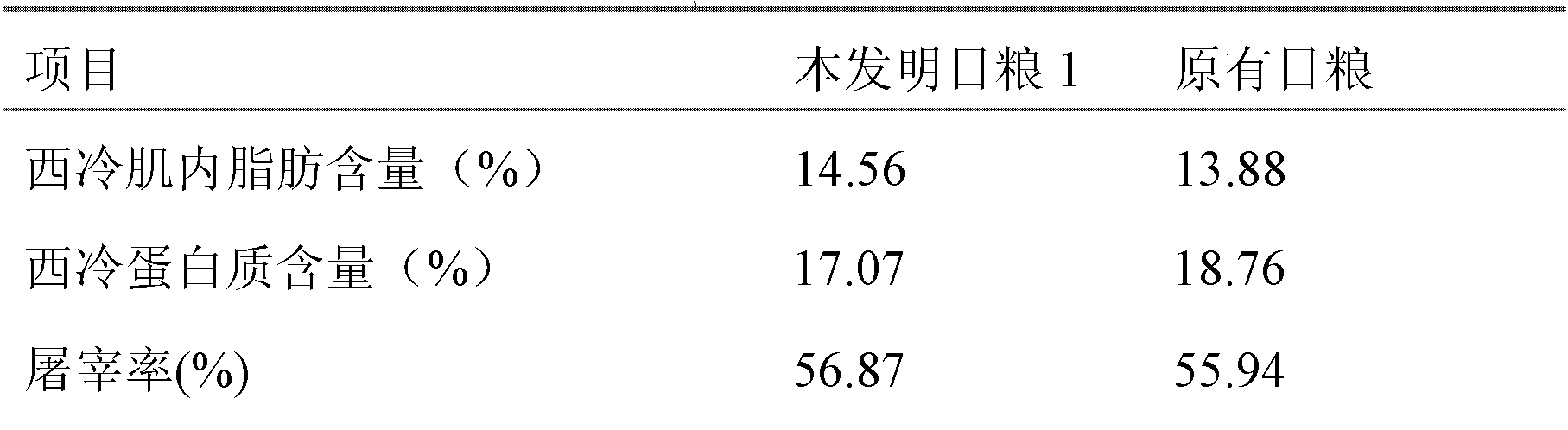

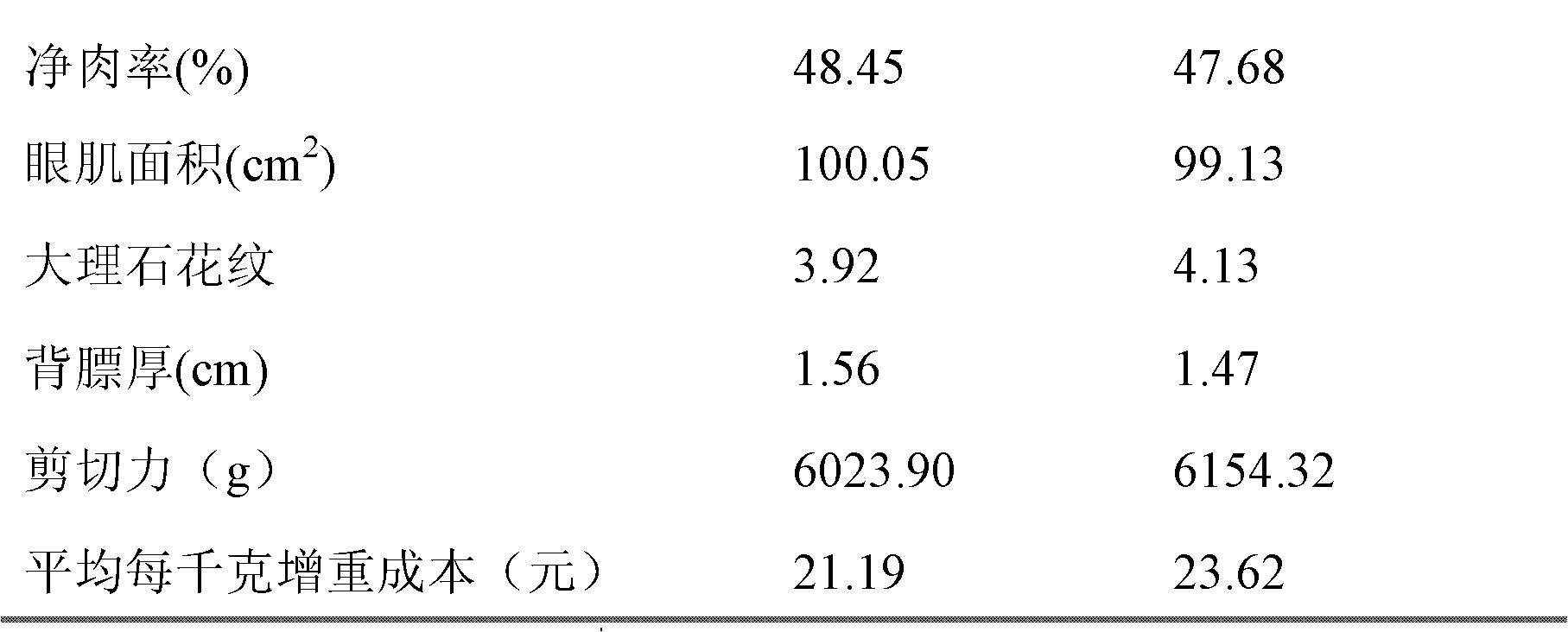

Embodiment 1

[0011] In a beef cattle farm, 24 first-generation steers were selected, which were 20-month-old Luxi yellow cattle and Japanese Wagyu cattle with a weight of about 450 kg. Divide into 2 groups at random, each group of 12, one group adopts the original feeding technology to prepare rations, and one group adopts the technology of the present invention to prepare rations (see Table 1). The diet was fed twice at 6:00 am and 4:00 pm every day. When feeding, the concentrate was first refined and then coarse. The concentrate was fed quantitatively at 1.5% of the body weight, and the actual feed amount was adjusted according to the roughage feed intake. Coarse material is free to eat, and each cow should be controlled at 0.5-1% of body weight per day. Free range, drink water after feeding. Feed for 180 days and then slaughter. The result shows that the ration adopted by the technology of the present invention is compared with the original ration, and there is no significant differen...

Embodiment 2

[0018] In a beef cattle farm, 20 first-generation steers were selected, which were 24-month-old Luxi yellow cattle and Japanese Wagyu cattle with a weight of about 600 kg. Divide into 2 groups at random, each group of 10, one group adopts the original feeding technology to prepare rations, and one group adopts the technology of the present invention to prepare rations (see Table 3). The diet was fed twice at 6:00 am and 4:00 pm every day. When feeding, the concentrate was first refined and then coarse. The concentrate was fed quantitatively at 1.5% of the body weight, and the actual feed amount was adjusted according to the roughage feed intake. Coarse material is free to eat, and each cow should be controlled at 0.5-1% of body weight per day. Free range, drink water after feeding. Feed for 180 days and then slaughter. The result shows that the ration adopted by the technology of the present invention is compared with the original ration, and there is no significant differen...

Embodiment 3

[0025] In a beef cattle farm, 30 first-generation steers were selected, which were 26-month-old Luxi yellow cattle and Japanese Wagyu cattle with a weight of about 650 kg. Divide into 2 groups at random, each group of 15, one group adopts the original feeding technology to prepare rations, and one group adopts the technology of the present invention to prepare rations (see Table 5). The diet was fed twice at 6:00 am and 4:00 pm every day. When feeding, the concentrate was first refined and then coarse. The concentrate was fed quantitatively at 1.5% of the body weight, and the actual feed amount was adjusted according to the roughage feed intake. Coarse material is free to eat, and each cow should be controlled at 0.5-1% of body weight per day. Free range, drink water after feeding. Feed for 180 days and then slaughter. The result shows that the ration adopted by the technology of the present invention is compared with the original ration, and there is no significant differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com