Ball slice folding machine of adhesive movement ball

An edge folding machine and movement technology, which is applied in the field of adhesive sports ball sheet edge folding machines, can solve problems such as product quality fluctuations, high labor intensity, and easy fatigue of workers, and achieve high and stable quality, reduce labor intensity, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

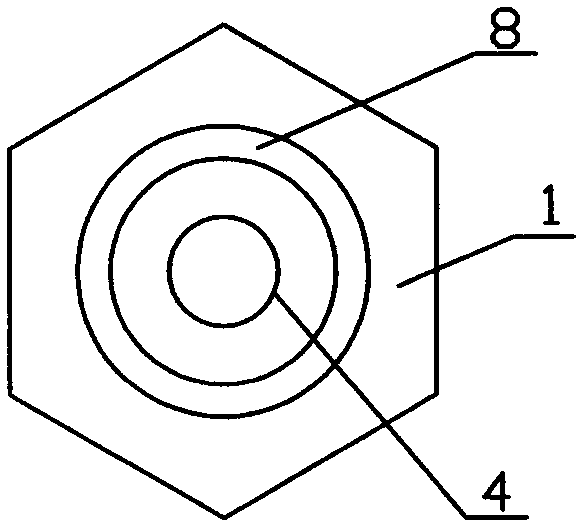

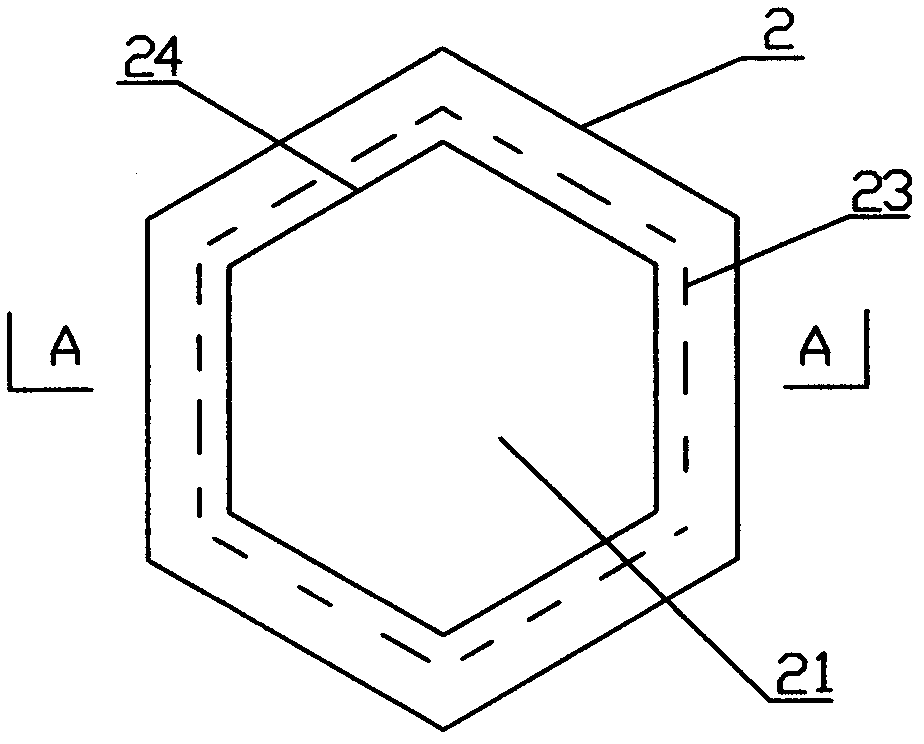

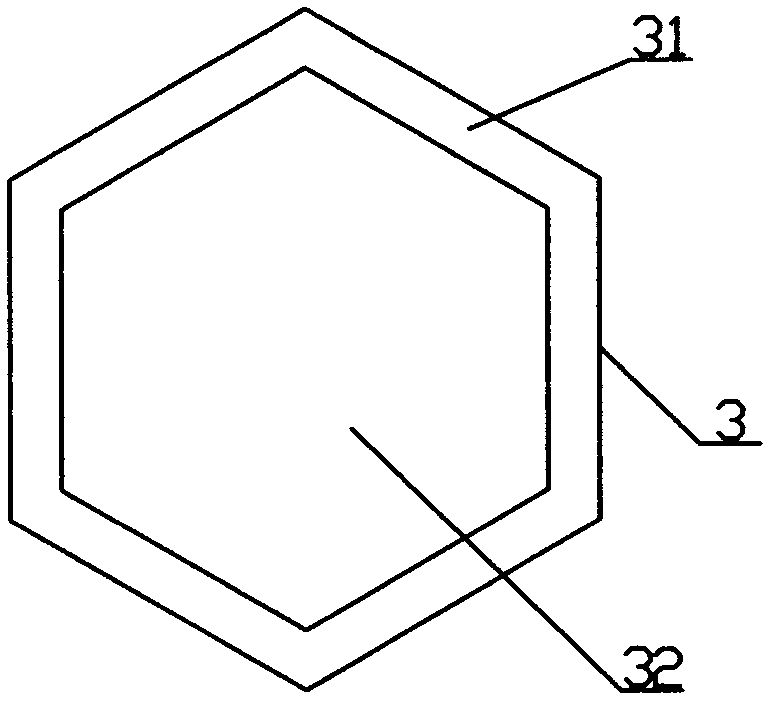

[0039] An adhesive sports ball sheet folding machine includes a mold and a pressure head. The mold is composed of a bottom mold, a ring mold and a top mold. The top mold is connected to the pressure head and is equipped with a high-frequency heating system. The pressure head is a hydraulic pressure head.

[0040] There are grooves around the bottom mold, and a convex ring matching the shape and size of the groove at the bottom of the ring mold. The shape and size of the top mold are the same as the cavity in the middle of the ring mold. In actual manufacturing, the top mold is slightly smaller than the cavity, so that It can enter the cavity.

[0041] The shape of the mold is mainly pentagonal, hexagonal, figure 1 , figure 2 , image 3 It is a hexagonal mold, and the mold is made of copper. The upper surface of the bottom mold, the inner surface of the ring mold and the lower surface of the top mold are all provided with Teflon coating.

[0042] Figure 13 , Figure 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com