Embedded type automatic blowback filter at top of catalyst tank

A filter and catalyst technology, applied in the direction of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of catalyst waste, environmental pollution, etc., to avoid secondary pollution, high recycling rate, and good filtering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

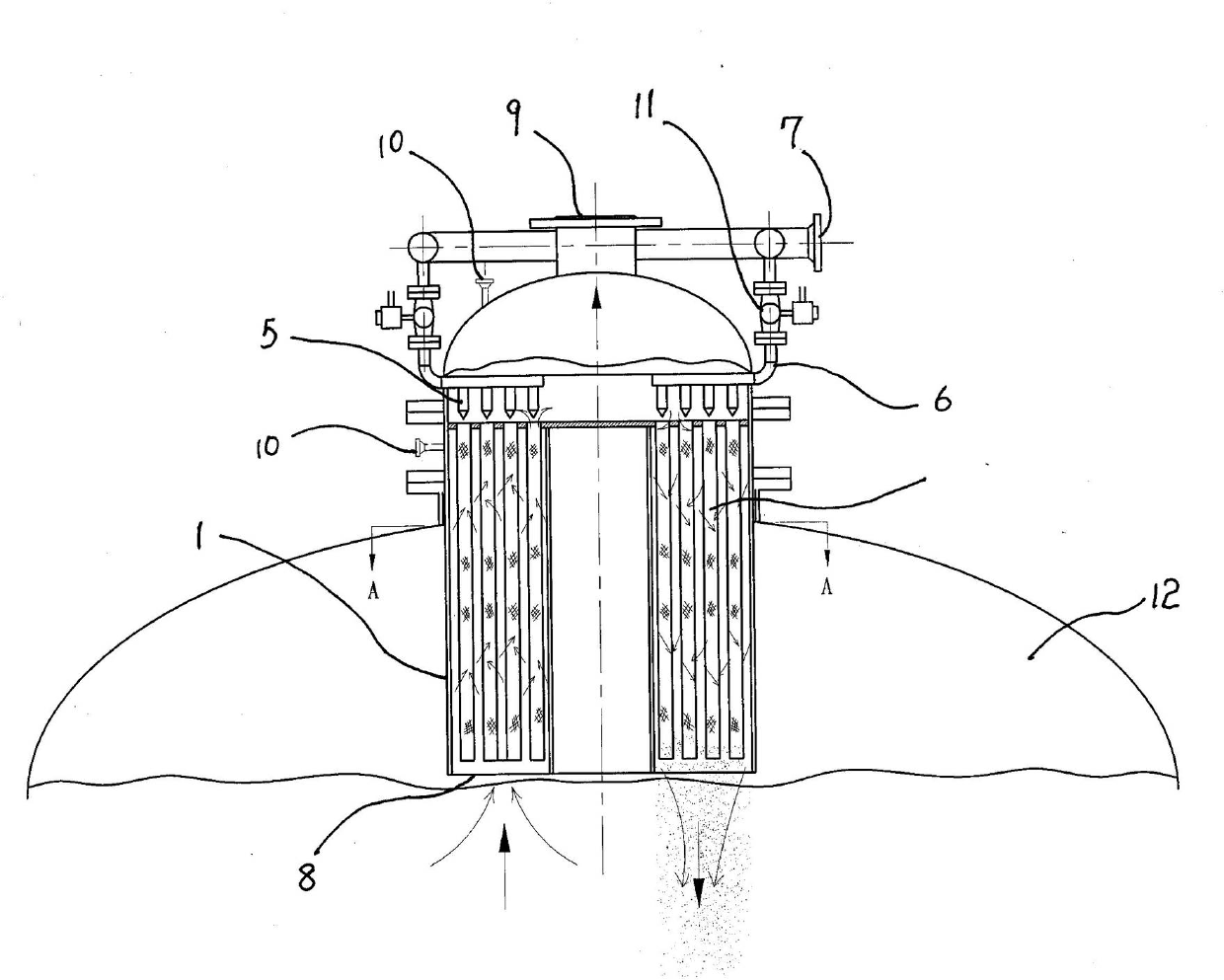

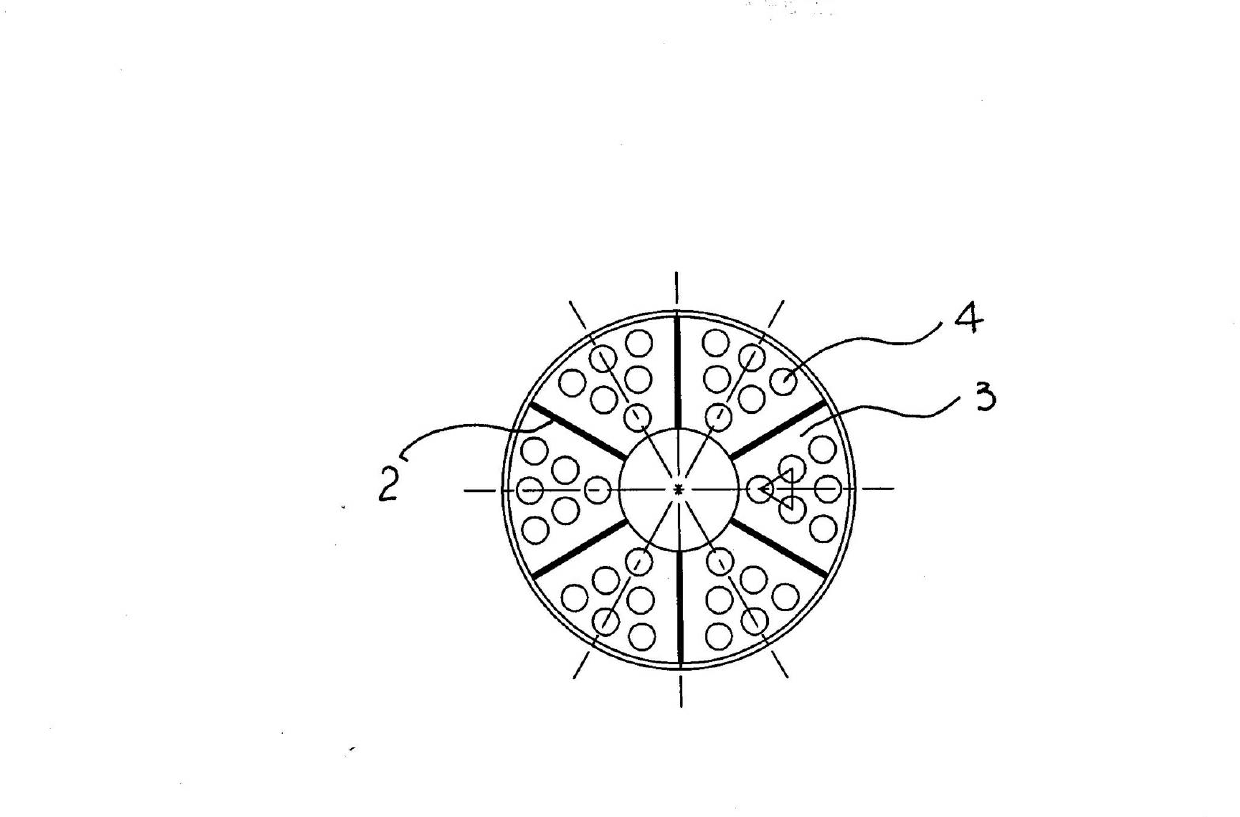

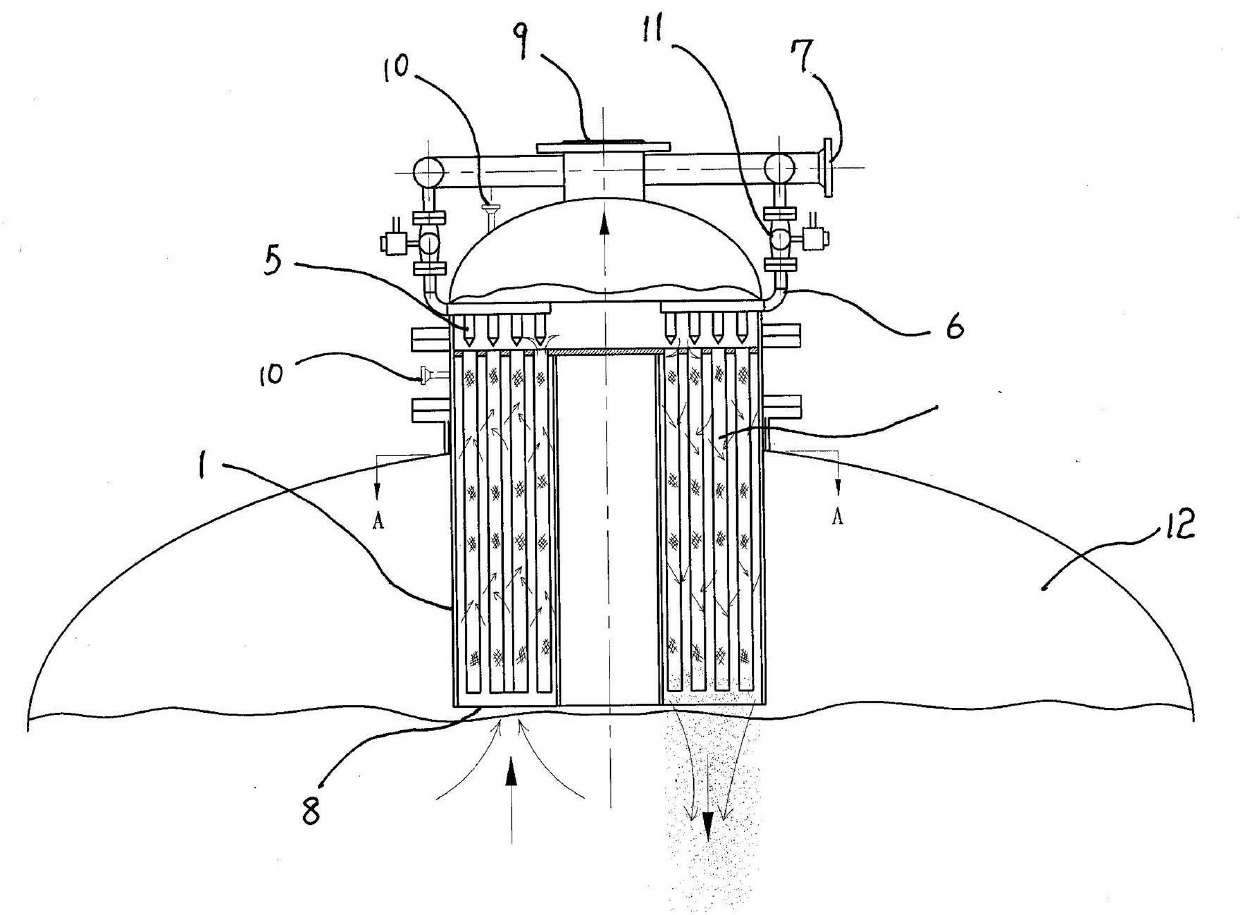

[0012] As shown in the figure, the present invention includes a housing 1, and a plurality of filter air chamber units 3 isolated from each other by a partition plate 2 are arranged in the housing 1. The design of the plurality of filter air chamber units 3 is not communicated with each other, and the purpose is to avoid reverse The dust blown off by the blowing group falls to the filter group being filtered next to it, so that the blown dust filter cake can smoothly fall to the accumulation level in the tank. The filter air chamber unit 3 is equipped with a filter element 4, the filter element can be a metal fiber sintered mesh filter tube, the filter surface of the filter tube is sintered by multi-layer metal fibers, and has a high filtering accuracy. A nozzle 5 is oppositely arranged above the top of the filter element 4, and the nozzle 5 adopts a supersonic ejection nozzle. The nozzle 5 is connected to the medium blowback inlet 7 through the pipeline 6, the bottom of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com