Die for preventing magnetic core from being cracked during sintering

A mold and magnetic core technology is applied in the field of molds to prevent sintering and cracking of magnetic cores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

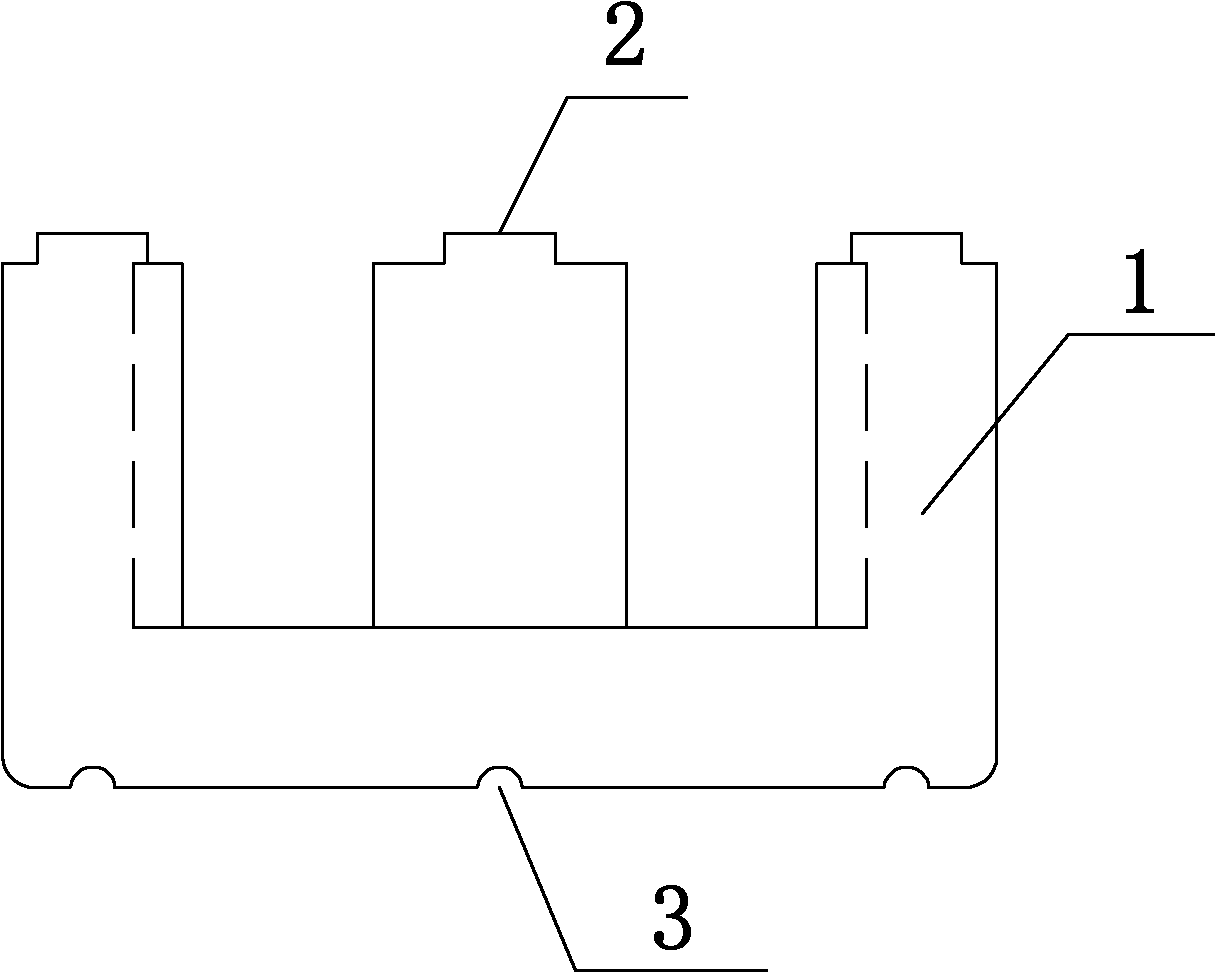

[0017] The mold to prevent the sintering and cracking of the magnetic core has a structure such as figure 1 As shown, the mold 1 is an E-shaped structure with a horizontal opening upwards, the inner side of the protruding parts at the left and right ends is an arc-shaped structure, and the middle protruding part is a cylindrical structure, which is set on the inner side of the top of the cylindrical structure and the top inner side of the left and right ends. A convex surface 2, the length of the convex surface 2 is 8mm, the width is 4mm, and the height is 0.5mm. The inner surface of the bottom of the mold 1 is provided with a concave point 3, the diameter of the concave point is 5mm, and the depth is 1mm.

Embodiment 2

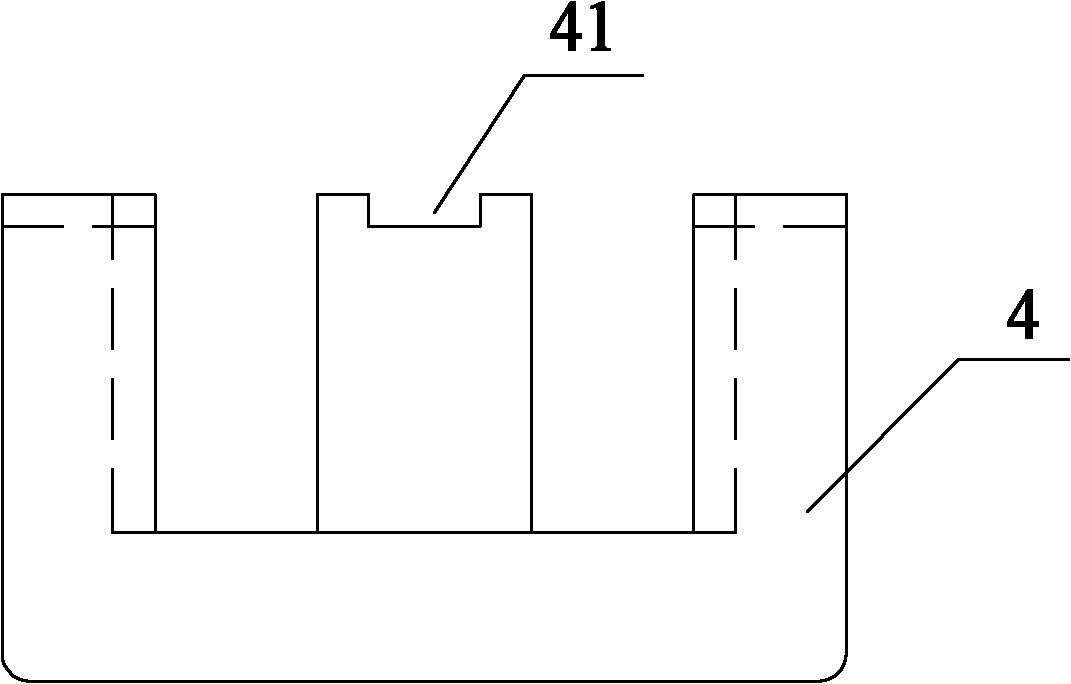

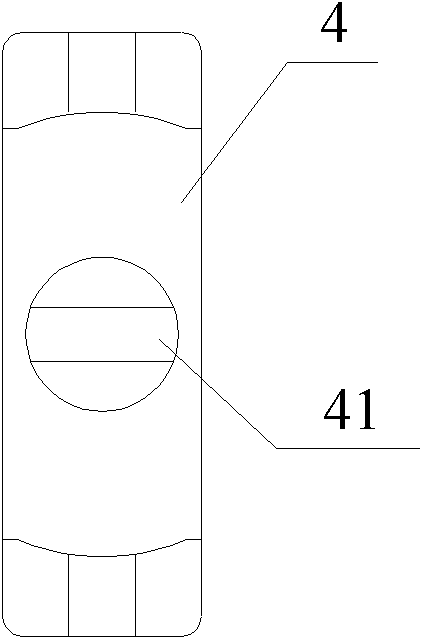

[0019] A mold for preventing sintering and cracking of the magnetic core. The mold is an E-shaped structure with a lateral opening upwards. The inner sides of the protruding parts at the left and right ends are arc-shaped structures, and the middle protruding part is a cylindrical structure. The convexity has a length of 5 mm, a width of 3 mm and a height of 0.3 mm. The magnetic core 4 fired by this mold is as Figure 2~3 As shown, the larger magnetic core 4 is easy to crack during sintering, and sometimes there is an internal pond core. In view of this situation, when designing the mold, the lower punch is made with a length of 5mm and a width of 3mm (taken according to the actual size of the product) different values), a convex surface with a height of 0.3mm, the surface of the blank of the formed magnetic core 4 will form a concave exhaust groove 41 with a length of 5mm, a width of 3mm, and a depth of 0.3mm. An exhaust channel is created, which is conducive to the drainage...

Embodiment 3

[0021] The mold to prevent the sintering and cracking of the magnetic core. The mold is an E-shaped structure with a lateral opening upwards. The inner side of the left and right protruding parts is an arc-shaped structure, and the middle protruding part is a cylindrical structure. There are three concave points on the inner surface of the bottom of the mold. The pit diameter is 3 mm and the depth is 0.5 mm. The magnetic core 4 fired by this mold is as Figure 4 As shown, the molded blank will be in contact with the sintered carrier (setter or push plate) during sintering, and sometimes cracks (mainly cracks) and crystal points of the bottom plate of the magnetic core 4 will occur. Usually, zirconium plates are placed or corundum or alumina powder is sprinkled to prevent the magnetic core from contacting the setter or push plate, but this operation will increase the production cost. In view of this situation, when designing the mold, a concave point with a diameter of 3mm and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com