Concentric welding method and device

A welding method and receiver technology, applied in auxiliary devices, welding media, welding equipment, etc., can solve the problems of tungsten steel bar strength not meeting quality requirements, oxidation blackening, solder hardening, etc., to ensure seamless welding. Process level, solve oxidation blackening, ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

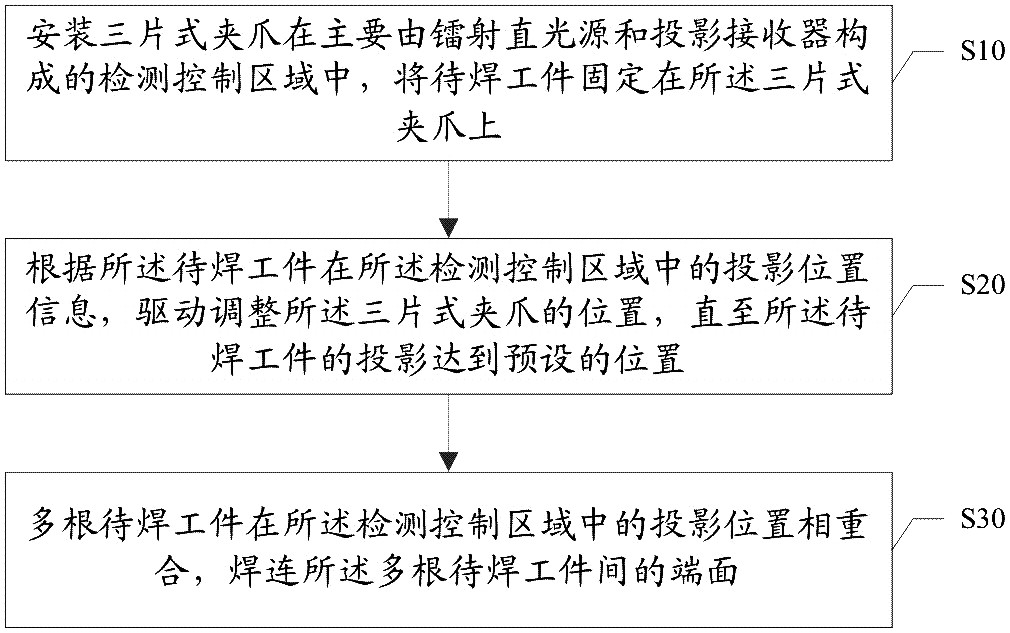

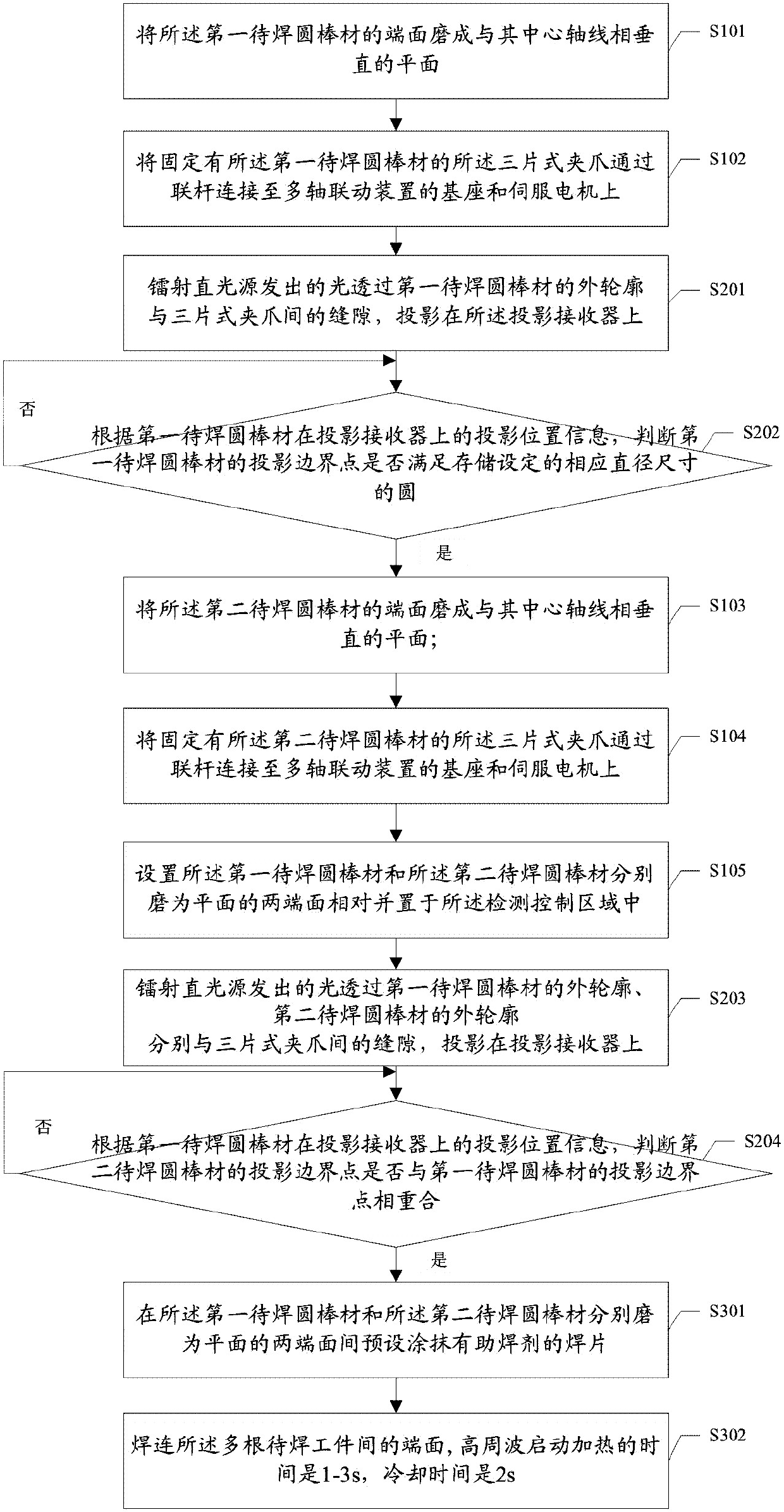

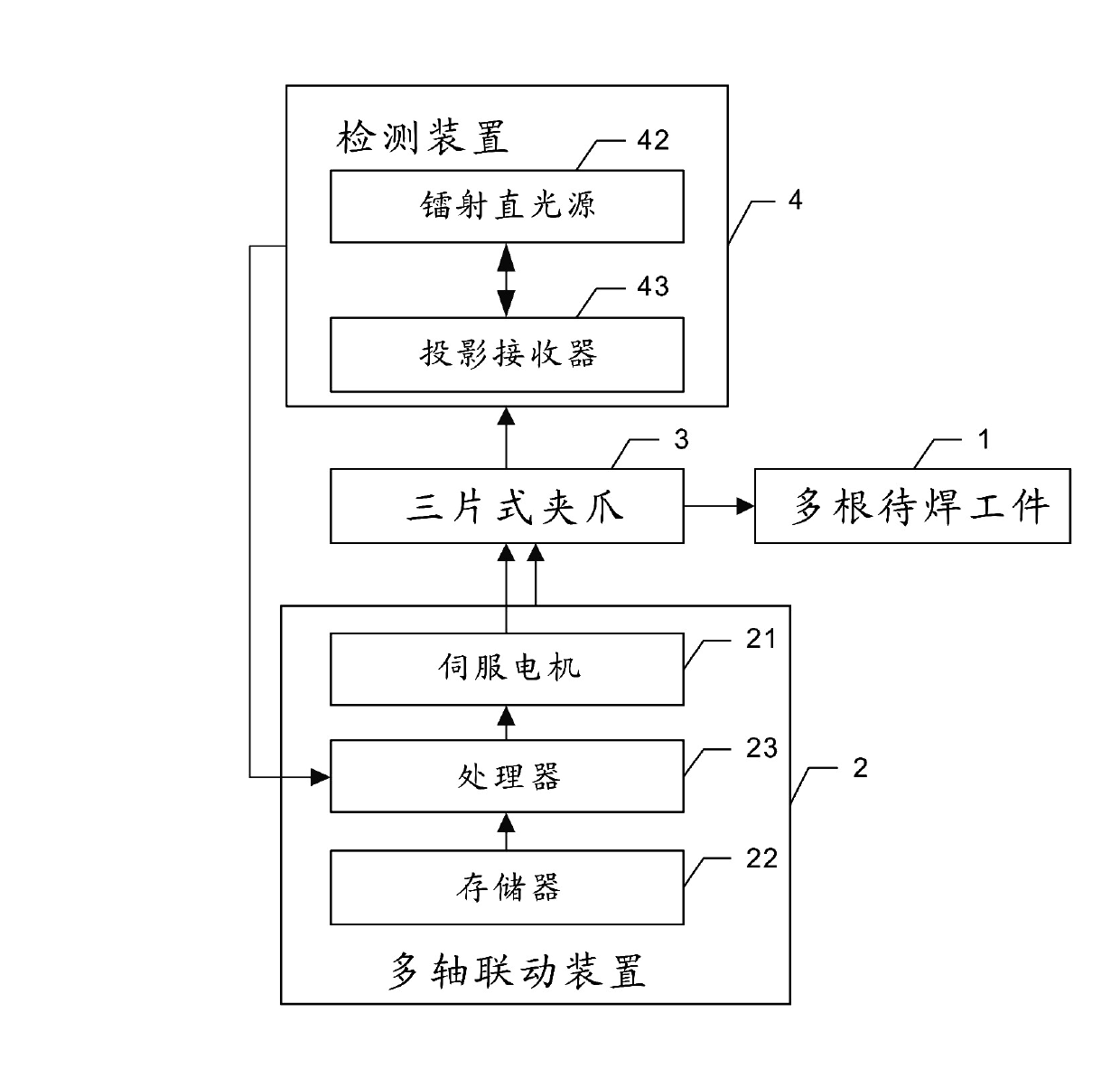

[0052] see figure 1 , the concentric welding method provided by the embodiment of the present invention is used to reprocess waste micro-drills and milling cutters used in PCB production into products by plane concentric welding, including the following steps:

[0053]Step S10, installing the three-piece gripper in the detection control area mainly composed of the laser direct light source and the projection receiver, and fixing the workpiece to be welded on the three-piece gripper;

[0054] Step S20, according to the projection position information of the workpiece to be welded in the detection control area, drive and adjust the position of the three-piece jaw until the projection of the workpiece to be welded reaches a preset position;

[0055] In step S30, the projection positions of the plurality of workpieces to be welded in the detection control a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com