Driving mechanism for die-assembling thrust base

A transmission mechanism and thrust seat technology, which is applied in the field of mold clamping parts of injection molding machines, can solve problems such as high energy consumption, difficult maintenance, and high noise, and achieve the effects of low energy consumption, small space occupation, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

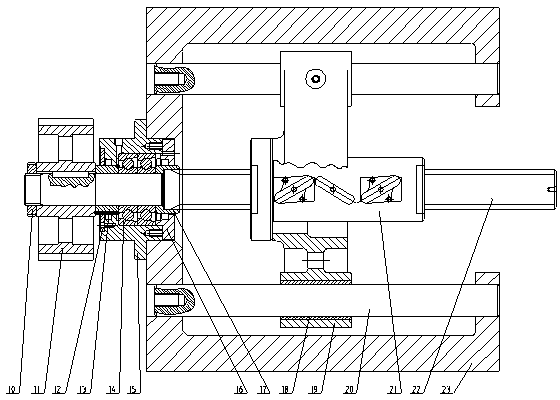

[0014] Such as figure 1 As shown, the tail plate 23 is composed of the rear wall surface and the left tail plate bracket 4 and the right tail plate bracket 5 fixed on the rear wall surface. There is a hole 1 on the left side of the tail plate and two holes 3 on the right side of the tail plate. There is a support hole coaxial with the hole 1 on the left side of the tail plate on the left bracket 4 of the tail plate. Hole 3 is coaxial with the support hole. The axis of the hole 1 on the left side of the tail plate, the axis of the hole 3 on the right side of the tail plate and the axis of the center hole 2 are parallel and in the same plane.

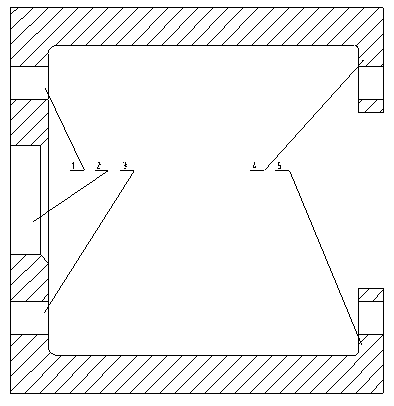

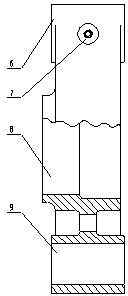

[0015] Such as figure 2 As shown, the center of the thrust seat 19 is the center hole 8 of the thrust seat, and the two sides of the center hole 8 of the thrust seat are symmetrically distributed with the left hole 6 of the thrust seat and the right hole 9 of the thrust seat, and the left hole 6 of the thrust seat and the right side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com