Machining-free puncture-resisting recycled tire

A processing-free and tire-free technology, which is applied to tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve the problems of reduced tire service life, reduced elasticity, poor tread anti-puncture ability, etc., to prolong the service life , improve the service life, the effect of strong anti-puncture ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

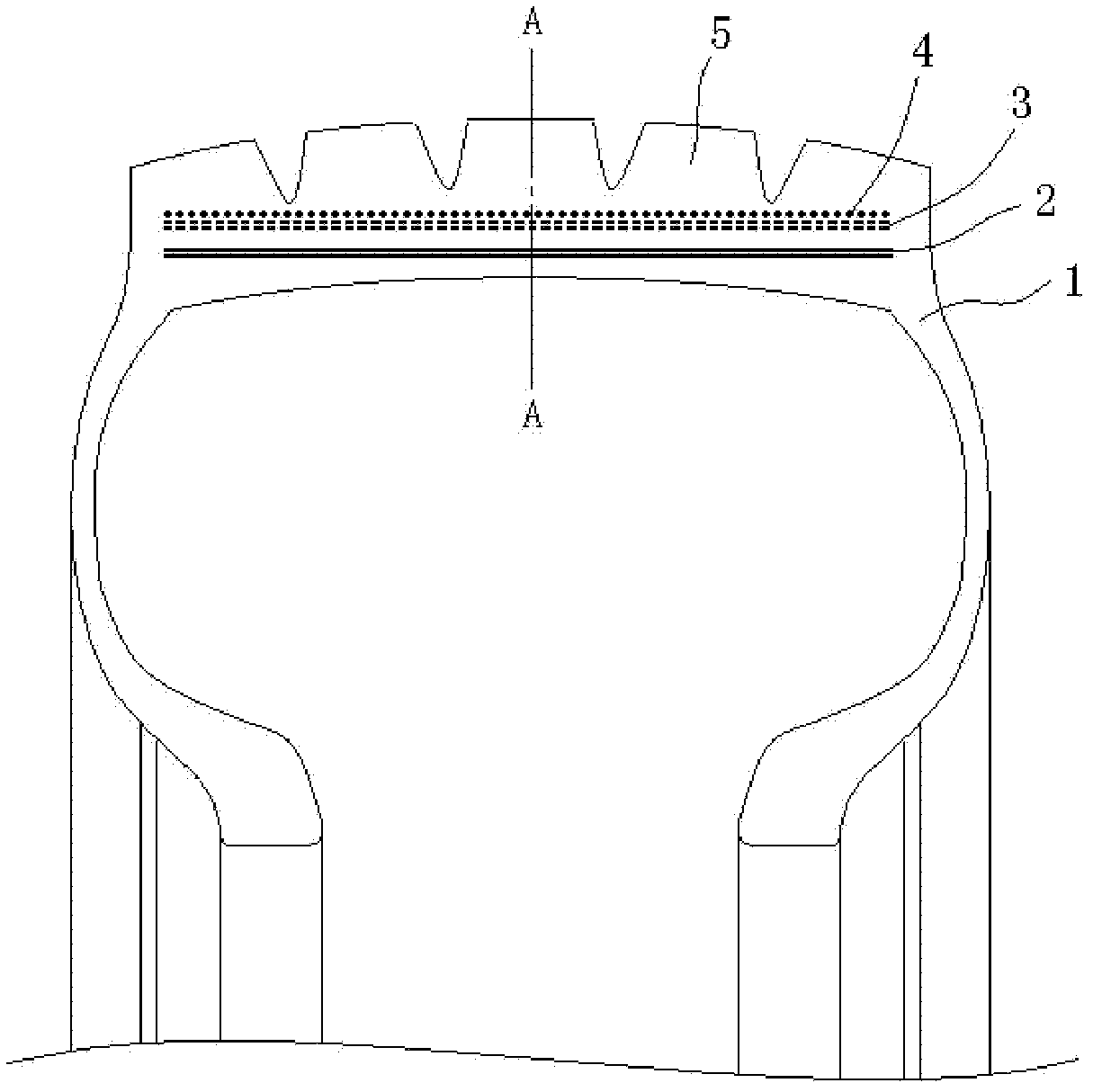

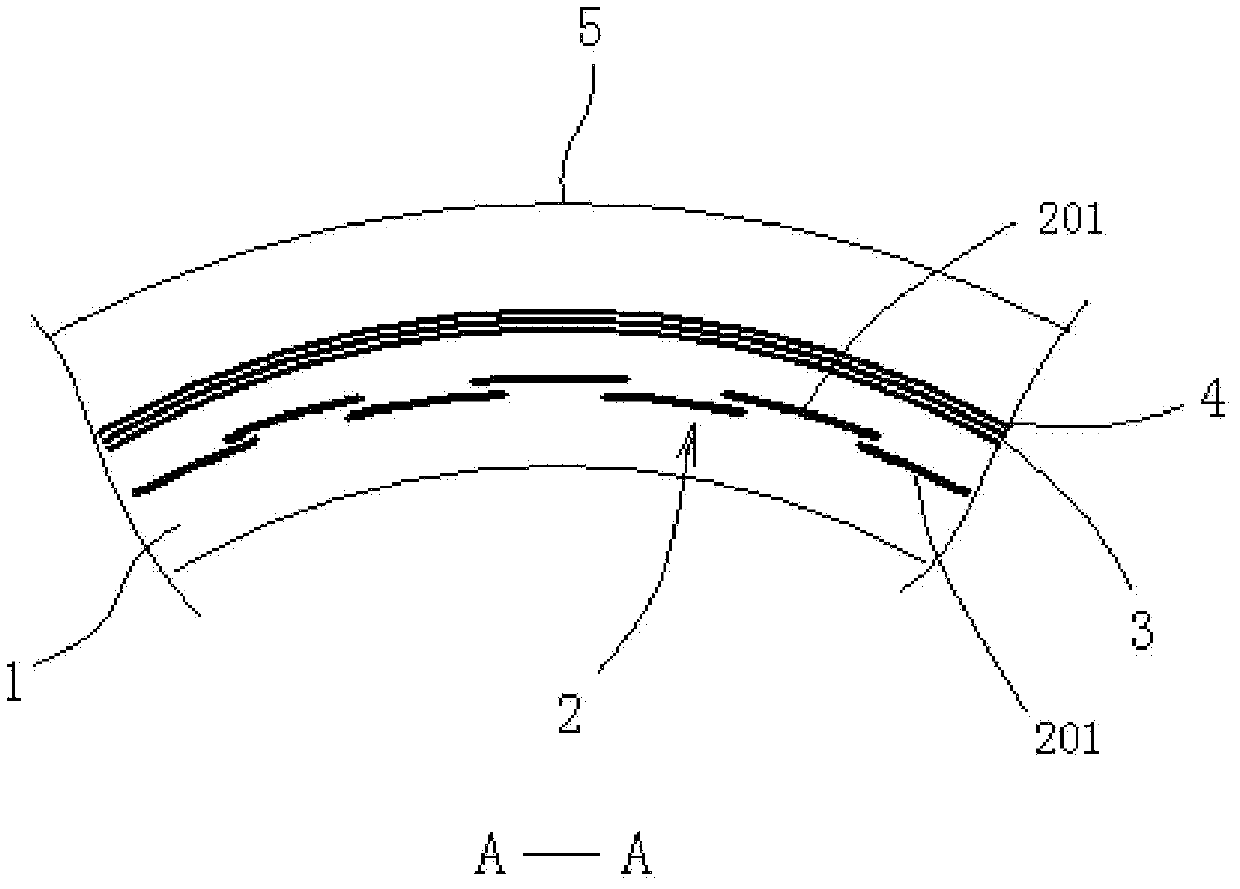

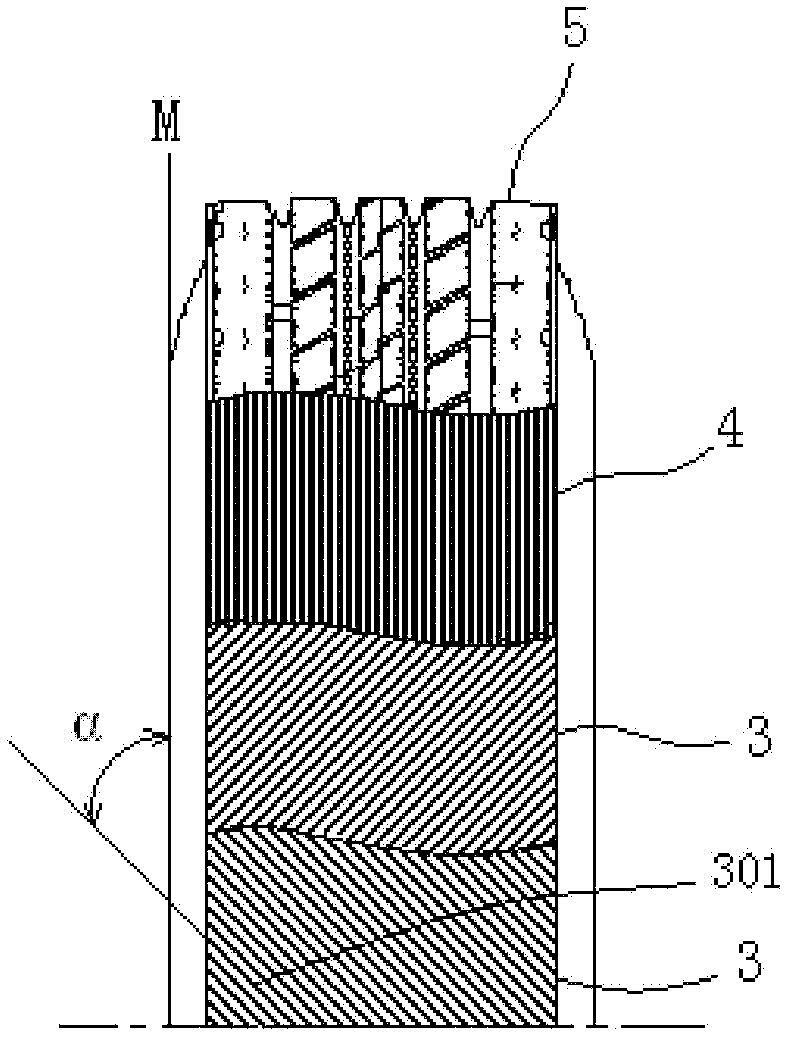

[0029] See Figure 1-Figure 3 , processing-free anti-puncture recycling tires, including a carcass 1 and a tread 5 vulcanized integrally with the carcass 1, three layers of belt layers are vulcanized in the tread 5, from the outside to the inside, the first layer is made of steel wire along the tire The spiral belt layer 4 is wound in the direction of rotation. The helix angle of the spiral belt layer 4 changes with the tire diameter, the diameter of the steel wire and the size of the steel wire interval. The second layer and the third layer are diagonal belts that cross each other. Belt layer 3; the angle α between the steel wire 301 in the bias belt layer 3 and the plane M where the tire rotation direction is located is 45°-75° (see image 3 ); anti-trap ring 2 is vulcanized in the carcass 1, and anti-trap ring 2 is made up of several anti-trap sheets 201 stacked on different circumferences by two circles, and anti-trap sheet 201 is as Figure 4 , Figure 5 As shown, there...

Embodiment 2

[0032] See Image 6 , the difference between this embodiment and implementation 1 is that the carcass 1 and the tread 5 adopt teeth and grooves to cooperate, and the teeth and grooves of the carcass 1 and the tread 5 cooperate to adopt two symmetrical curved annular teeth 501a, 501b and grooves; Such as Figure 7 As shown, the inner surface of the tread 5 is provided with two symmetrical curved ring teeth 501a, 501b, and several reinforcing ribs 502 are arranged between the two teeth. The carcass 1 is provided with the curved ring teeth 501a, 501b corresponding to the curved ring groove; such as Figure 8 As shown, curved annular teeth 101a, 101b can also be set on the carcass 1, a number of reinforcing ribs 102 are arranged between the two teeth, and curved annular grooves are correspondingly arranged on the tread 5; The diagonal belt layer 3 is used to replace the anti-piercing ring.

[0033] When the tire is inflated, the carcass 1 has no helical belt layer 4 and expands...

Embodiment 3

[0035] See Figure 9 , The carcass 1 and the tread 5 of this embodiment adopt tooth and groove cooperation, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com