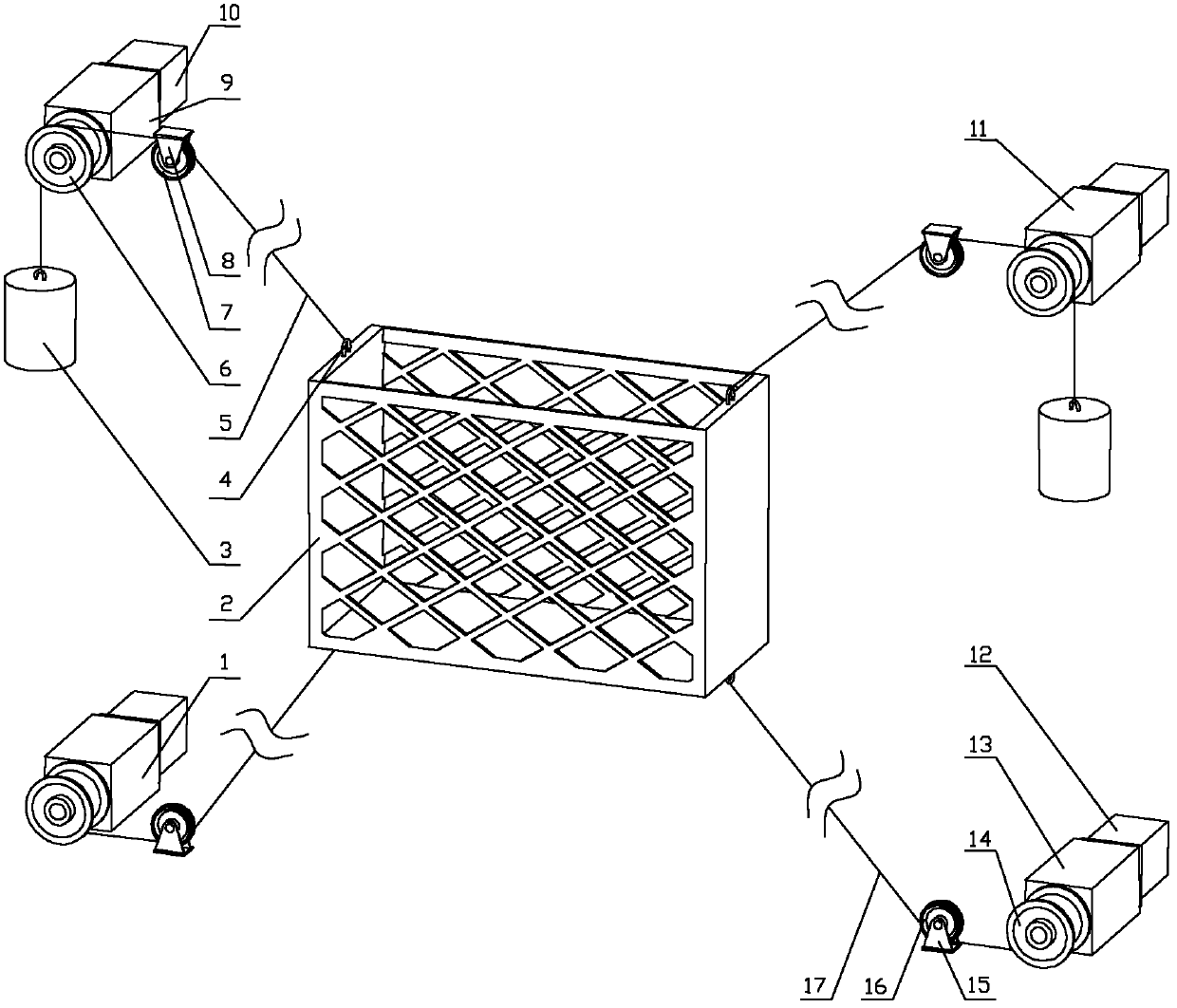

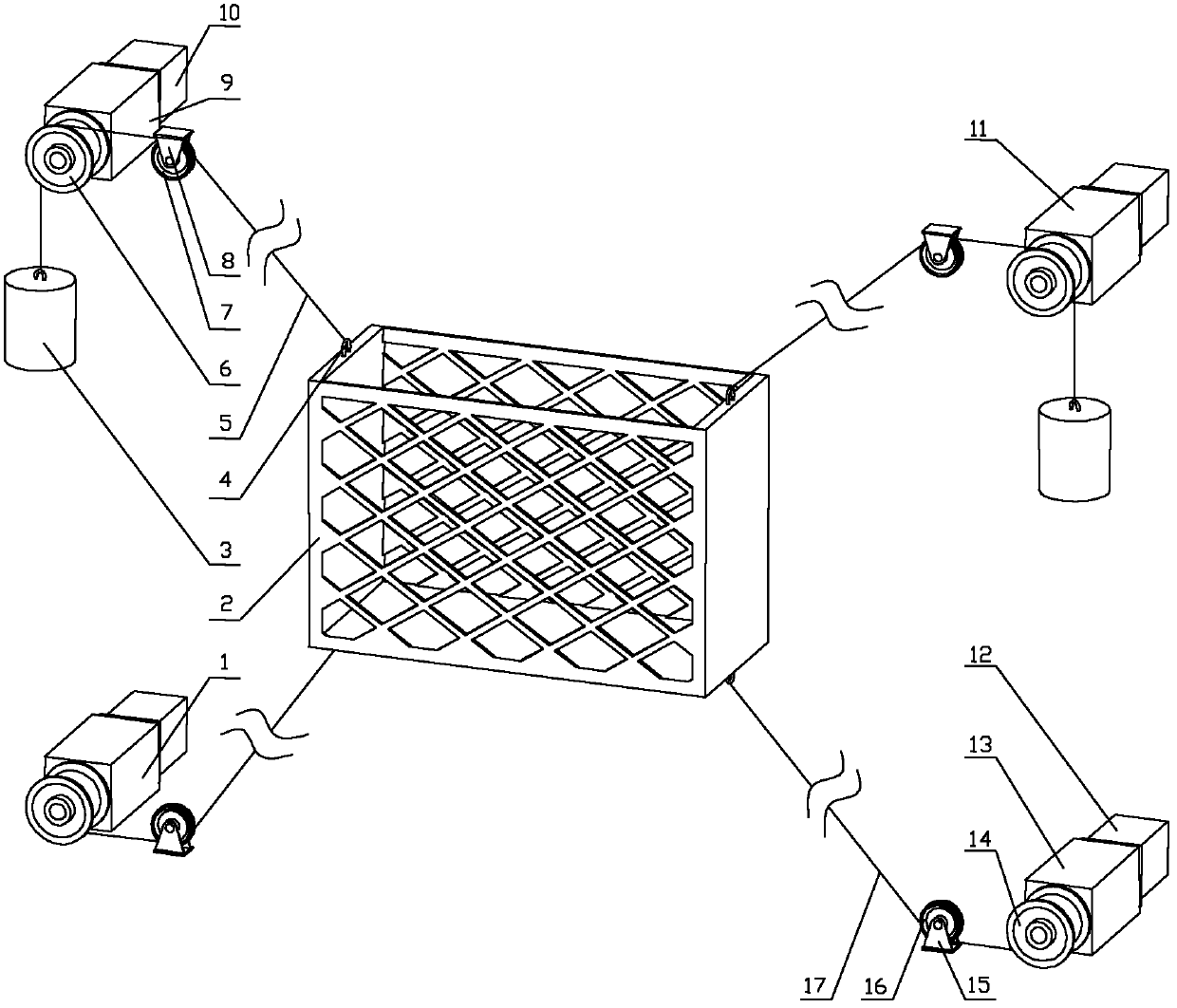

Wire-traction wall lifting and carrying combining mechanism

A rope traction and wall technology is applied in the field of rope traction wall hoisting and carrying parallel mechanisms, which can solve the problems of small working range, unstable horizontal direction of the carrying basket, and horizontal operation, etc. The effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] see figure 1 , the embodiment of the present invention is provided with loading basket 2, 2 groups with counterweight driving device 11, 2 groups without counterweight driving device 1 and 2 counterweight blocks 3; the loading basket 1 is provided with 4 lifting lugs 4 , the 2 sets of counterweight driving devices 11 are located above the two sides of the loading basket 2, and the 2 groups of counterweight driving devices 11 are provided with an upper drive motor 10, an upper reducer 9, a friction drum 6, an upper Set the fixed pulley 7, the upper bracket 8 and the upper wire rope 5; the upper fixed pulley 7 is fixed on the wall through the upper bracket 8; one end of the upper wire rope 5 is fixed on the loading basket 2 The lifting lug 4 is connected, and the other end of the upper wire rope 5 is connected with the counterweight 3 through the upper fixed pulley 7 and the friction drum 6; , the 2 groups of non-counterweight driving devices 1 are provided with a lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com